A method for removing low-concentration ammonia nitrogen in water by using ozone and trace amounts of calcium peroxide

A low-concentration ammonia nitrogen and calcium peroxide technology, applied in the field of low-concentration ammonia nitrogen, can solve problems such as complex process, slow processing speed, and high equipment requirements, and achieve the effect of increasing dissolved oxygen content, improving dissolved oxygen content, and obtaining safe and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

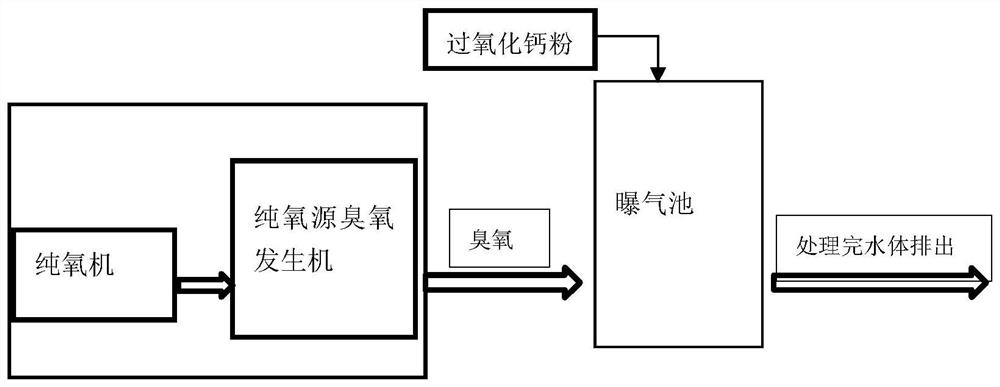

[0035] Apparatus used in the method of the invention:

[0036] Pure oxygen generator:

[0037] The present invention uses a pure oxygen machine to produce pure oxygen, and adopts a pure oxygen generator with an oxygen flow rate of 3L / min.

[0038] Ozone generator:

[0039] The ozone generator that the present invention adopts is that power is 15g / H ozone generator (QLO-15G220v / 50hz, 3.4A, 750W), and oxygen source is 3L / min pure oxygen generator, and pure oxygen generator is built-in in the ozone generator , the total power is 750w.

[0040] Aeration (gas-liquid mixing) reaction device:

[0041] According to the requirements of the actual environment, gas-liquid mixing uses a gas-liquid mixing pump and an ejector to mix ozone and water to be treated.

[0042] The present invention utilizes ozone and trace calcium peroxide to remove the method for low-concentration ammonia nitrogen in water body, and its steps are as follows:

[0043] Add 0.01g / L calcium peroxide powder to ...

Embodiment 2

[0047] Apparatus used in the method of the invention:

[0048] Pure oxygen generator:

[0049] The present invention uses a pure oxygen machine to produce pure oxygen, and adopts a pure oxygen generator with an oxygen flow rate of 3L / min.

[0050] Ozone generator:

[0051]The ozone generator that the present invention adopts is that power is 15g / H ozone generator (QLO-15G220v / 50hz, 3.4A, 750W), and oxygen source is 3L / min pure oxygen generator, and pure oxygen generator is built-in in the ozone generator , the total power is 750w.

[0052] Aeration (gas-liquid mixing) reaction device:

[0053] According to the requirements of the actual environment, gas-liquid mixing uses a gas-liquid mixing pump and an ejector to mix ozone and water to be treated.

[0054] The present invention utilizes ozone and trace calcium peroxide to remove the method for low-concentration ammonia nitrogen in water body, and its steps are as follows:

[0055] Add 0.001g / L calcium peroxide powder to ...

Embodiment 3

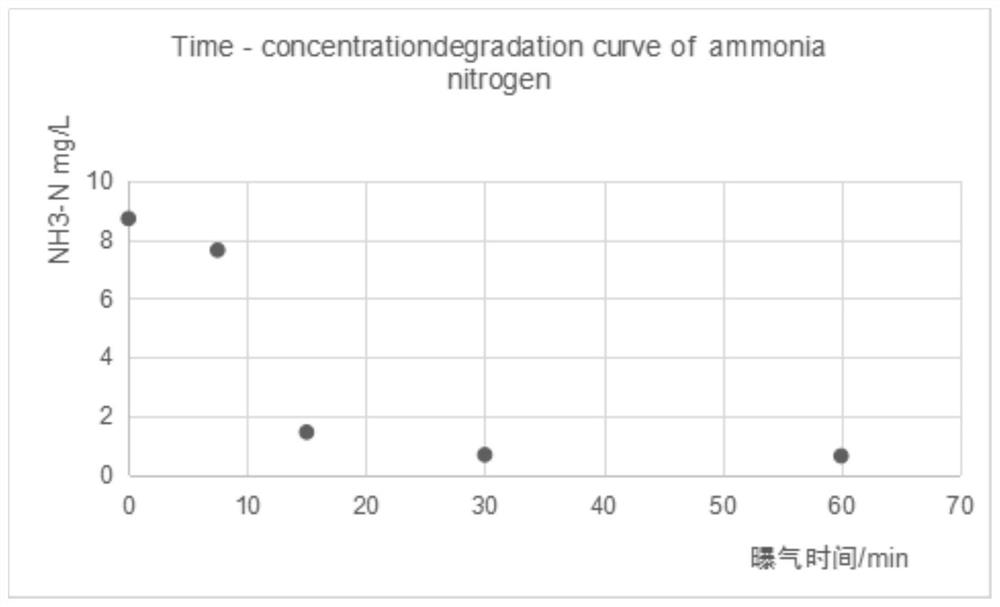

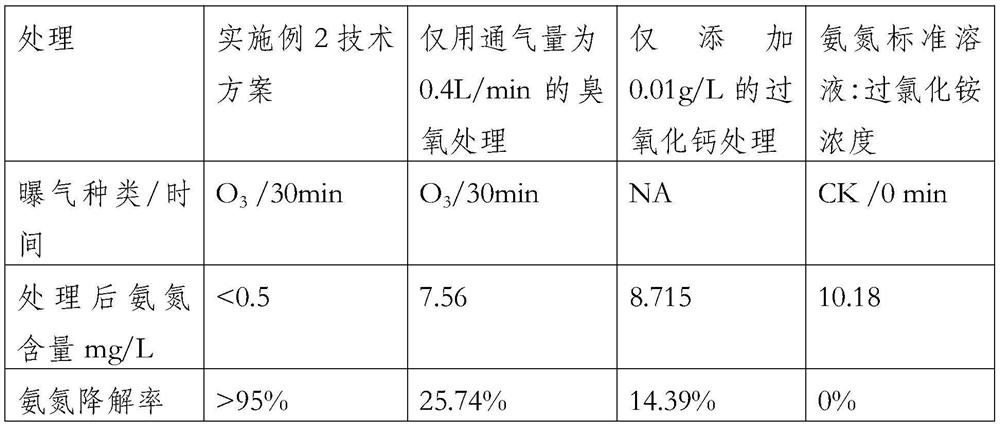

[0060] Prepare 10mg / L ammonia nitrogen standard solution by ammonium chloride, test the effect of the method for embodiment 2 removal ammonia nitrogen and comparative experiment:

[0061] Ammonia nitrogen standard solution with an initial content of about 10mg / L was prepared by using ammonium chloride as the experimental reflection liquid, using a plexiglass tube reaction device with a diameter of 50mm, adding 400ml of the experimental reflection liquid, and the dosage of calcium peroxide was to make the water body over The calcium oxide concentration is 0.001g / L, the aeration time is 30min, and the ozone ventilation content in the reaction device is 0.4L / min. After the reaction, use the national standard Nessler's reagent to measure the ammonia nitrogen content in the water body, and the results are included in the school. The control groups are only treated with ozone with a ventilation rate of 0.4L / min, and only 0.01g / L of calcium peroxide. The comparative experimental resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com