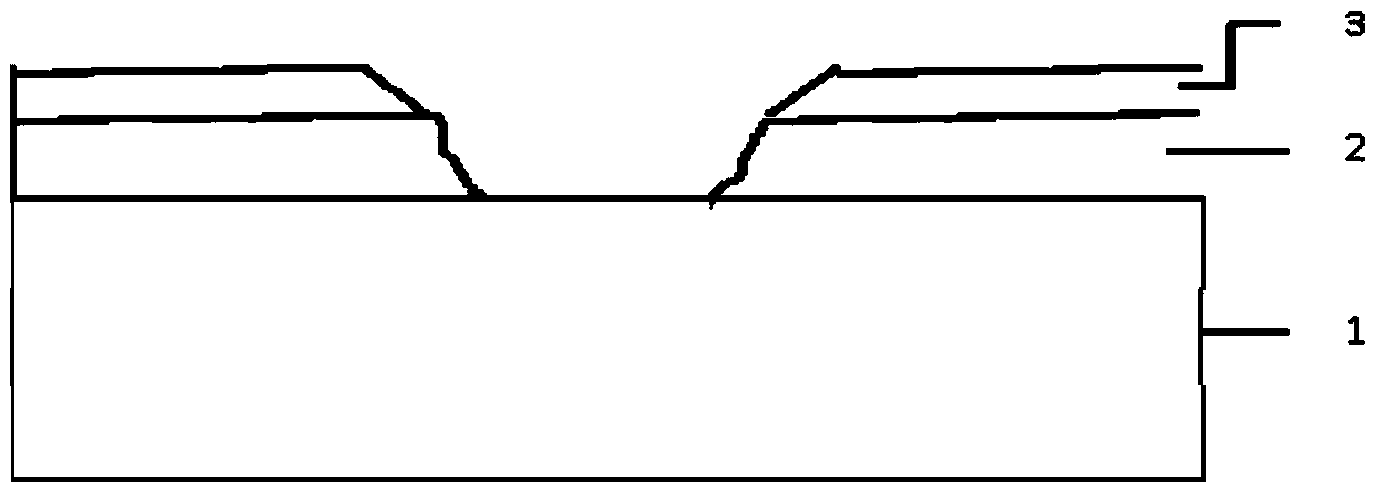

SiC etching method for gentle and smooth side wall morphology

A smooth, topographic technology that can be used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to solve problems such as narrowing of mask strip widths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Cleaning SiC material:

[0031] The SiC material 1 to be etched is sequentially subjected to the following cleaning steps:

[0032] 1# cleaning solution (ammonia: hydrogen peroxide: pure water = 1:1:5), temperature 70° for 5 minutes; 2# cleaning solution (hydrochloric acid: hydrogen peroxide: pure water = 1:1:5), temperature 70° for 5 minutes 1 minute; BOE cleaning solution (hydrofluoric acid: ammonium fluoride = 1:20), room temperature, time 30 seconds; acetone ultrasonic 5 minutes; isopropanol ultrasonic 5 minutes; DI water rinse 5 minutes, dry, and set aside.

[0033] 2) Deposit a loose mask layer:

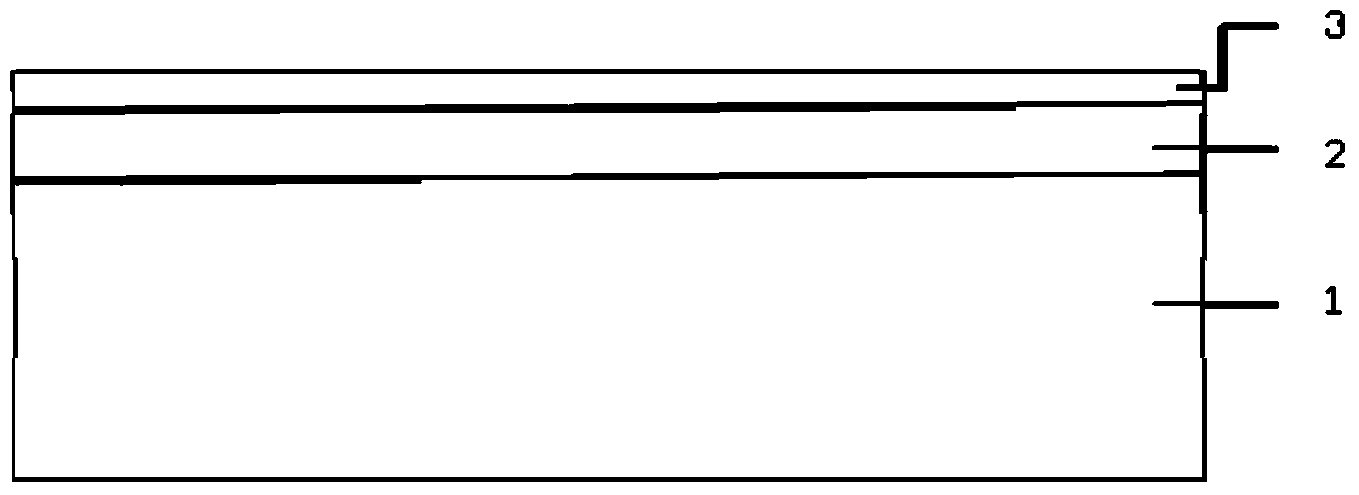

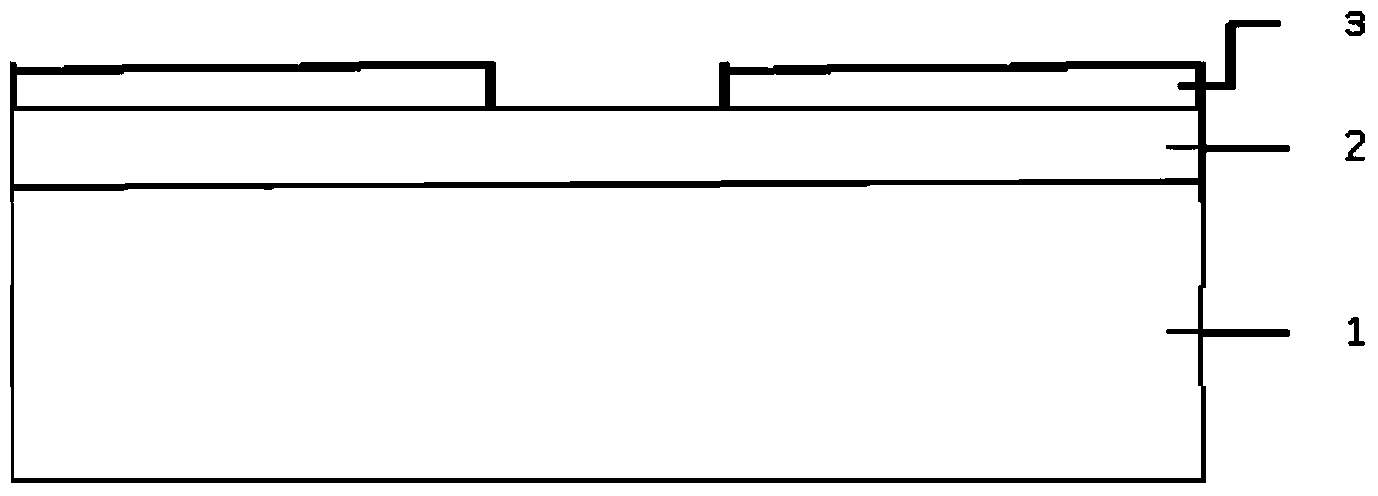

[0034] Using PECVD, namely plasma enhanced chemical vapor deposition method, room temperature deposition mask layer 2, its chemical composition is SiO2, see figure 1 . According to the thickness of the SiC material 1 to be etched 2um and the etching selectivity ratio 2, it is determined that the thickness of the mask layer 2 to be deposited is not less than 1um. Co...

Embodiment 2

[0050] 1) Cleaning SiC material:

[0051] The SiC material 1 to be etched is sequentially subjected to the following cleaning steps:

[0052] 1# Cleaning solution (ammonia: hydrogen peroxide: pure water = 1:1:5), temperature 70° for 5 minutes; BOE cleaning solution (hydrofluoric acid: ammonium fluoride = 1:20), room temperature, time 30 seconds; 2 #Cleaning solution (hydrochloric acid: hydrogen peroxide: pure water = 1:1:5), temperature 70° for 5 minutes; BOE cleaning solution (hydrofluoric acid: ammonium fluoride = 1:20), room temperature, time 30 seconds; isopropyl Alcohol ultrasonication for 5 minutes; acetone ultrasonication for 5 minutes; isopropanol ultrasonication for 5 minutes; DI water rinse for 5 minutes, dry and set aside.

[0053] 2) Deposit a loose mask layer:

[0054] Using ICPCVD, i.e. plasma enhanced chemical vapor deposition method, room temperature deposition mask layer 2, its chemical composition is SiON, see figure 1 . According to the thickness of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com