A silicon oxynitride etching method with gentle and smooth sidewall morphology

A technology of silicon oxynitride and silicon oxynitride materials, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of narrow process window, affect device performance, increase reverse current, etc., to achieve a wide process window, The effect of solving process defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Cleaning silicon oxide material:

[0029] The 500nm silicon oxide 1 on the silicon to be etched is followed by the following cleaning steps:

[0030] 1# cleaning solution (ammonia: hydrogen peroxide: pure water = 1:1:5), temperature 70° for 5 minutes; 2# cleaning solution (hydrochloric acid: hydrogen peroxide: pure water = 1:1:5), temperature 70° for 5 minutes 5 minutes for ultrasonication with acetone; 5 minutes for ultrasonication with isopropanol; 5 minutes for DI water rinse, dry and set aside.

[0031] 2) Photolithography, the process flow is as follows:

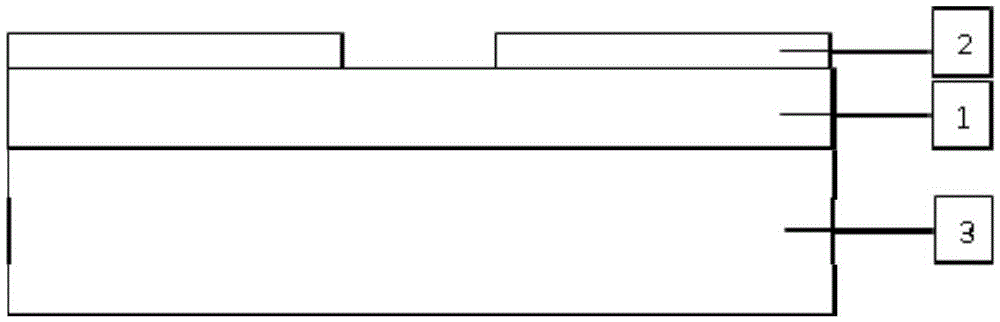

[0032] Vapor-coated tackifier; spin-coated photoresist 3, type 5214, thickness 1.6um; pre-bake at 95 degrees Celsius for 90 seconds; SUSSMA6 lithography machine contact exposure for 7 seconds; develop with 3038 developer for 45s; 110°, 60s to harden the film ,See figure 1 .

[0033] 3) Wet corrosion:

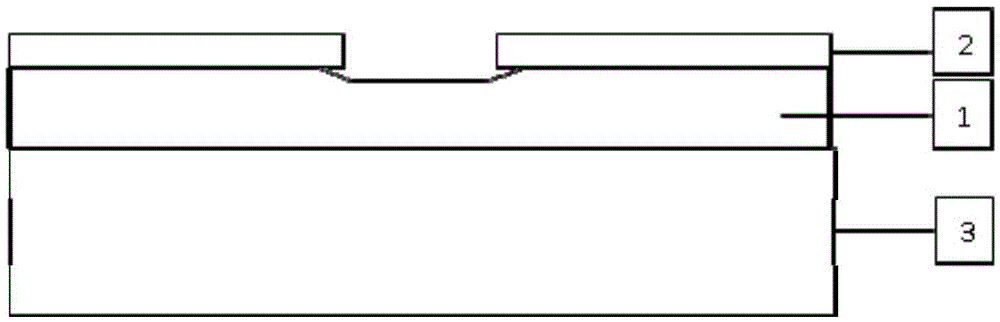

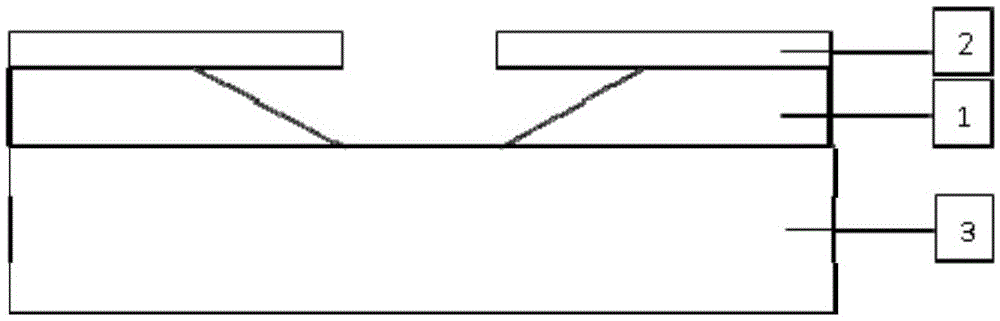

[0034] Wet etching silicon oxide 1 to achieve the purpose of gentle initial steps, the specific process ...

Embodiment 2

[0043] 1) Cleaning silicon nitride material:

[0044] The 500nm silicon nitride material 1 on the silicon to be etched is sequentially subjected to the following cleaning steps:

[0045] 1# cleaning solution (ammonia: hydrogen peroxide: pure water = 1:1:6), temperature 70° for 4 minutes; 2# cleaning solution (hydrochloric acid: hydrogen peroxide: pure water = 1:1:7), temperature 70° for 6 5 points; isopropanol ultrasonication 5 points; acetone ultrasonication 5 points; isopropanol ultrasonication 5 points;

[0046] 2) Photolithography, the process flow is as follows:

[0047] Vapor-coated tackifier; spin-coated photoresist 3, type 5214, thickness 1.6um; pre-bake at 95 degrees Celsius for 90 seconds; SUSSMA6 lithography machine contact exposure for 7 seconds; develop with 3038 developer for 45s; 110°, 60s to harden the film ,See figure 1 .

[0048] 3) Wet corrosion:

[0049] Wet etching silicon nitride material 1 to achieve the purpose of smoothing the initial step, the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com