Method for single-stage vanadium extraction in same converter

A single vanadium extraction and converter technology, which is applied in the manufacture of converters, etc., can solve the problems of large heat loss and the reduction of scrap steel processing, and achieve the effect of solving large heat loss and reducing energy consumption in the converter process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

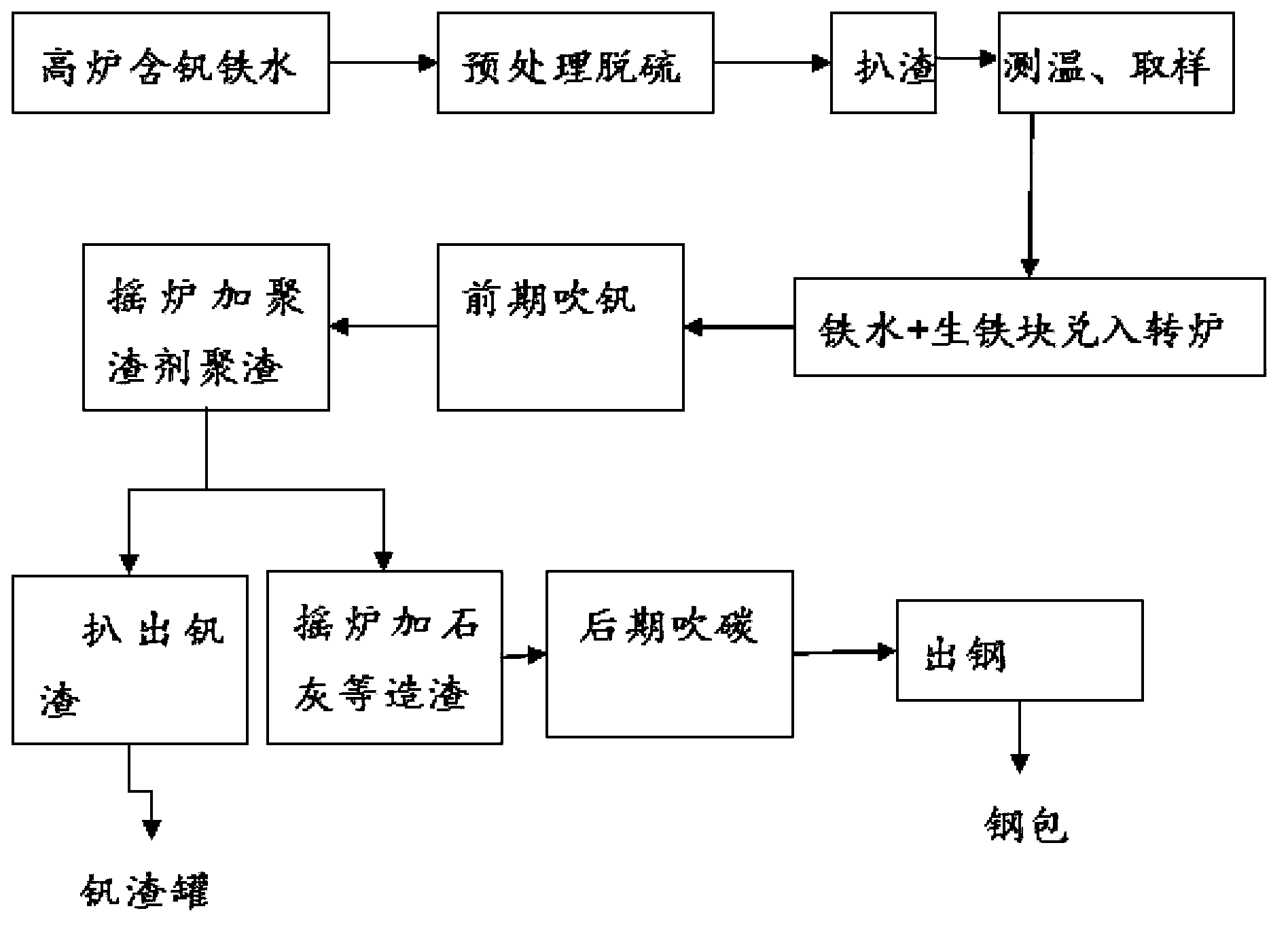

[0026] The method for extracting vanadium in the same furnace single-connected converter provided in this embodiment comprises the following steps:

[0027] (1) Put the vanadium-containing molten iron into the converter, and the charging amount is controlled at 82.0 tons / furnace. The carbon content of the molten iron is 3.6% to 0.20%. The temperature of the molten iron is 1290°C, and the total content of silicon, manganese and titanium is 0.90%. , the total content of silicon and titanium is 0.60%;

[0028] (2) Desulfurization of molten iron pretreatment, desulfurization of molten iron to 0.070%;

[0029] (3) Remove the slag in the molten iron so that the amount of slag in the molten iron is 0.5%;

[0030] (4) Temperature measurement and sampling of molten iron. The composition and temperature of molten iron in the furnace must meet the requirements of steps (1) and (2). Mix the molten iron + pig iron into the converter;

[0031] (5) Vanadium blowing in the early stage, the ...

Embodiment 2

[0040] The method for extracting vanadium in the same furnace single-connected converter provided in this embodiment comprises the following steps:

[0041] (1) Put the vanadium-containing molten iron into the converter, and the charging amount is controlled at 79.0 tons / furnace. The carbon content of the molten iron is 5.8%, the vanadium content is 0.40%, the temperature of the molten iron is 1250°C, and the total content of silicon, manganese and titanium is 0.50%, the total content of silicon and titanium is 0.40%;

[0042] (2) Desulfurization of molten iron pretreatment, desulfurization of molten iron to 0.030%;

[0043] (3) Remove the slag in the molten iron so that the amount of slag in the molten iron is 0.2%;

[0044] (4) Temperature measurement and sampling of molten iron. The composition and temperature of molten iron in the furnace must meet the requirements of steps (1) and (2). Mix the molten iron + pig iron into the converter;

[0045] (5) In the early stage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com