Vertical milling lathe complex machining center

A compound machining center and vertical milling technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., to achieve the effect of improving equipment life, simple structure, and large clamping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

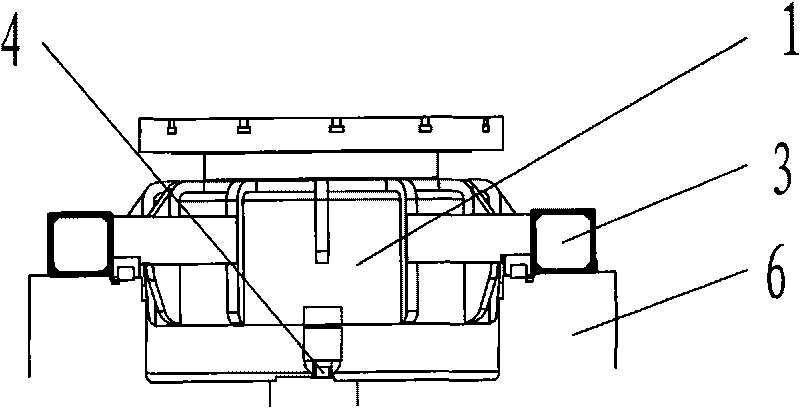

[0020] Such as Figure 4 As shown, the direct-drive external rotor torque motor used in the vertical milling and turning compound machining center of the present invention includes a torque motor stator 111, a rotor 110, a clamping device 109 for braking, a motor cooling device for cooling, and a pendulum Other auxiliary structures used in the head, such as encoder 103, encoder bracket 101, spindle box 102, turning and milling spindle 104, bearing gland 105, turntable bearing 106, bearing housing 107, housing 108, base plate 112, etc.

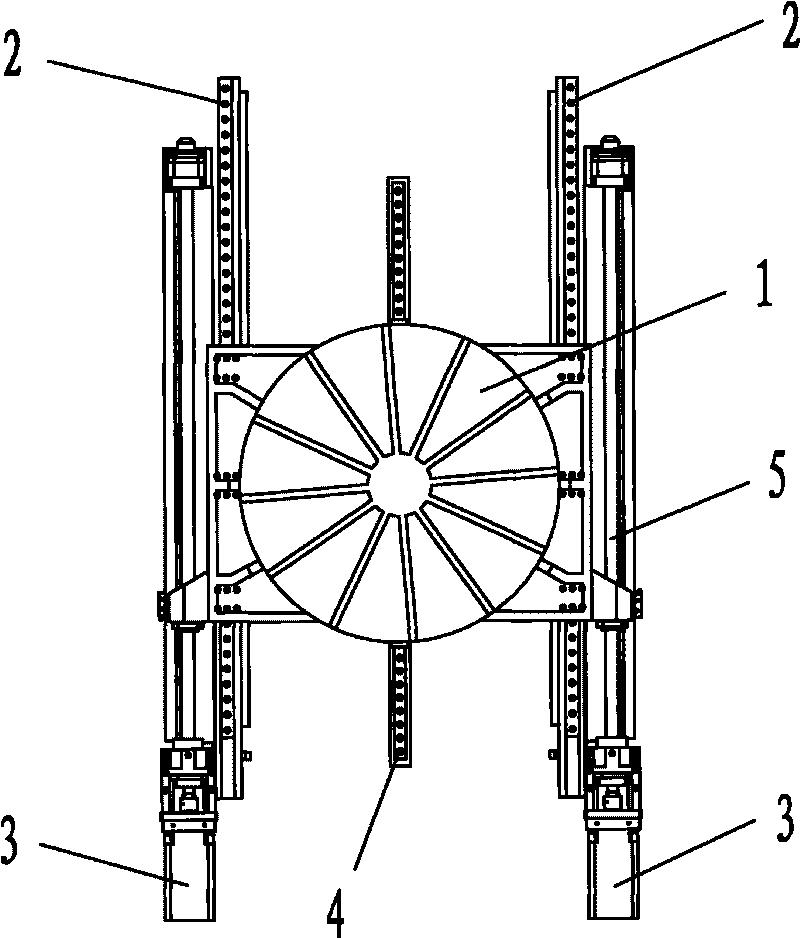

[0021] Such as image 3 The structure of the vertical milling-turning compound machining center shown in the present invention includes a bed 6 arranged horizontally, and two columns 7 arranged on one side of the bed 6 vertically. The bed 6 is provided with two rows of parallel X-axis side support line rails 2 and X-axis screw 5, and the single-axis turntable 1 sits on the two rows of X-axis rails 2, and the horizontal seat frame 99 of the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com