Drum type laundry machine

A drum-type washing machine, drum technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of insufficient convenience of use, and achieve the effects of increased reliability, high reliability, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

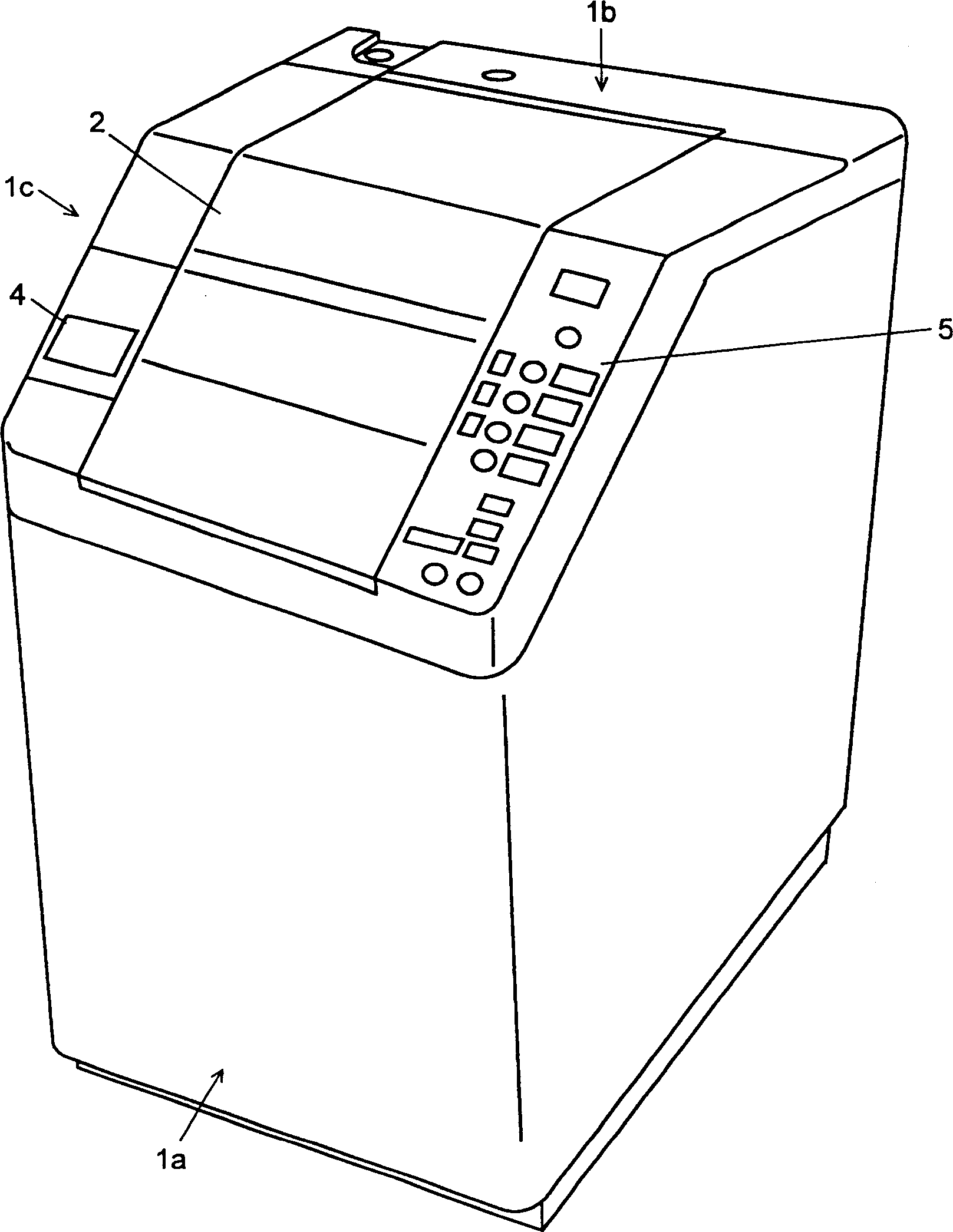

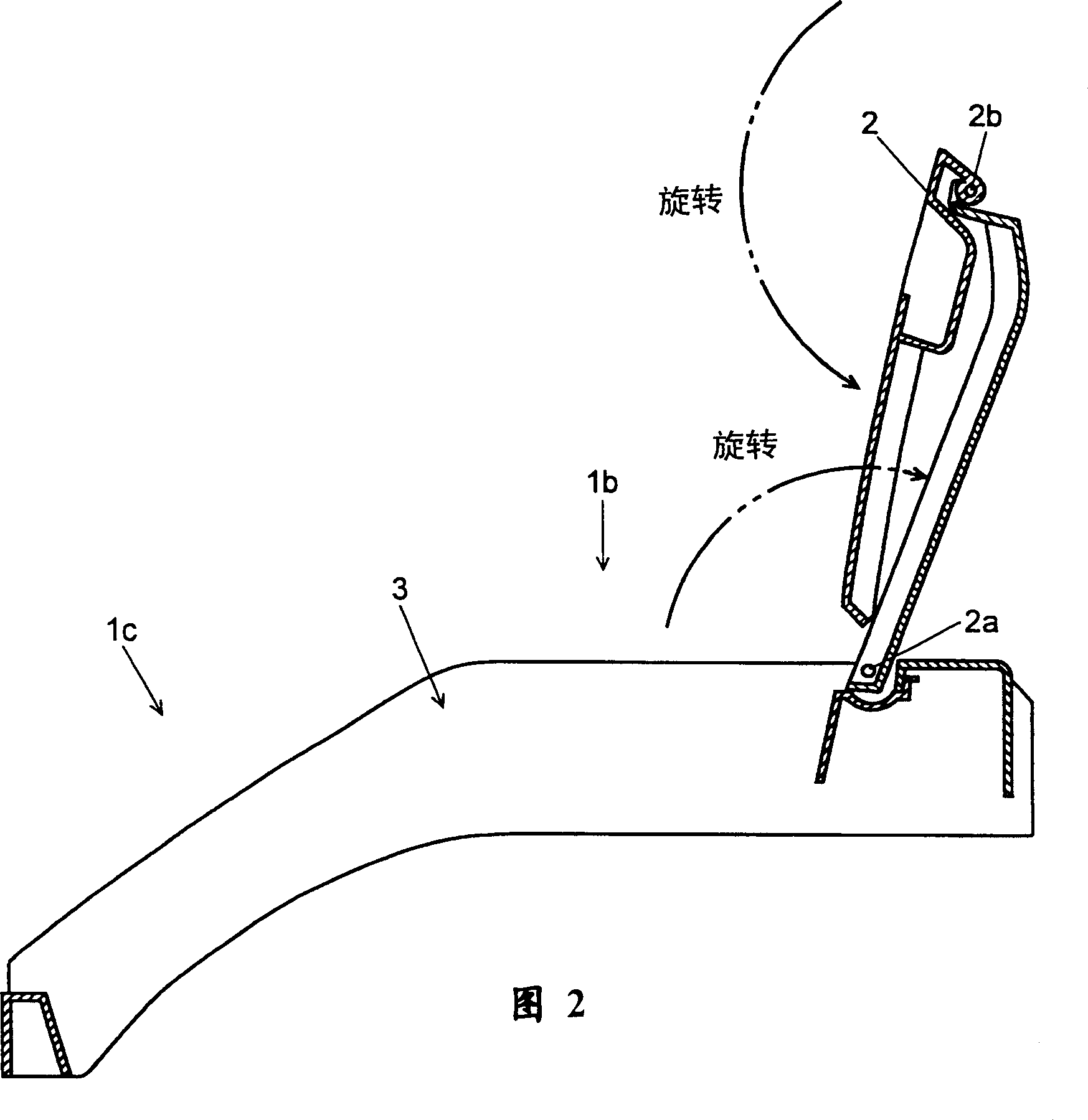

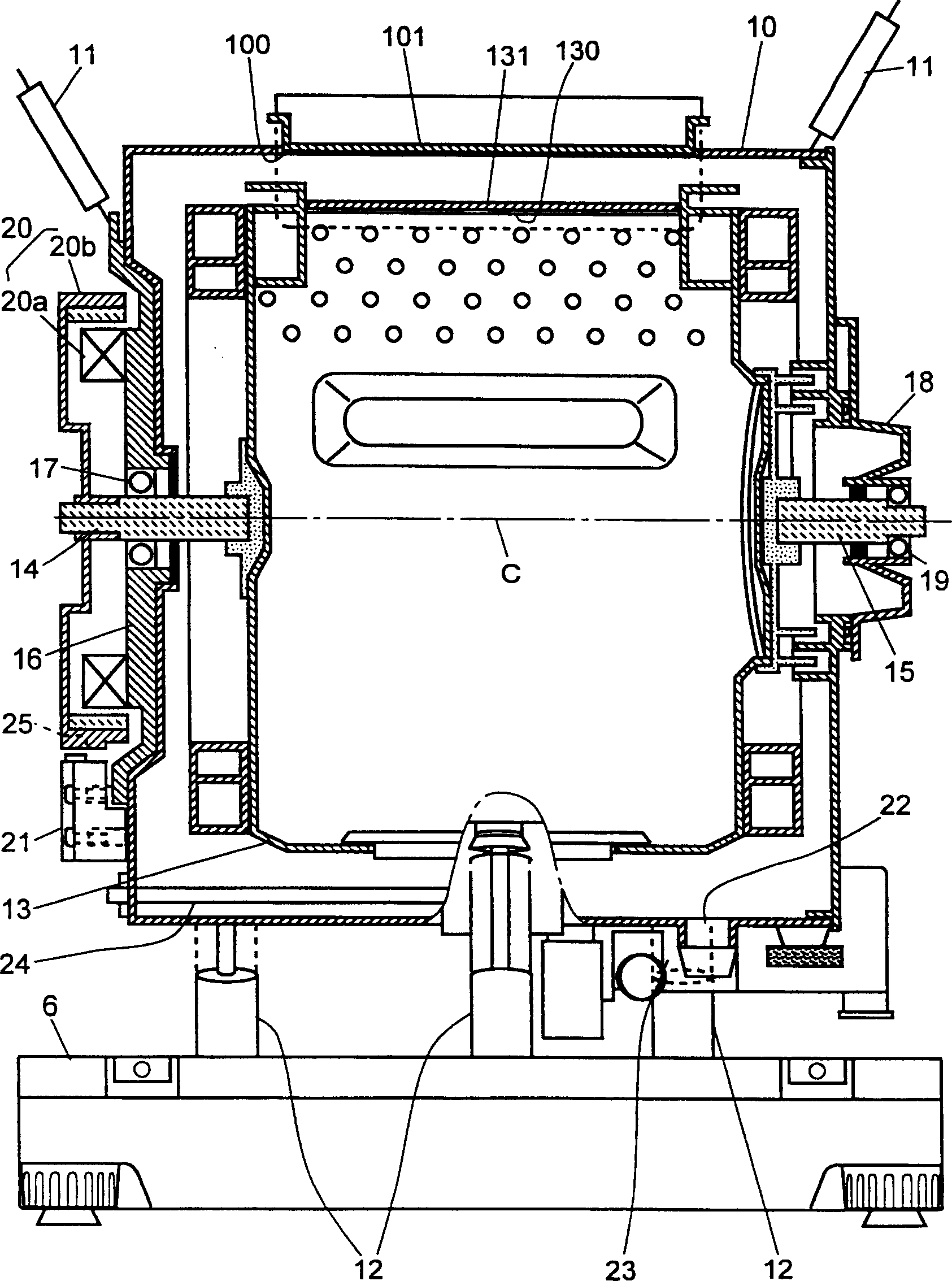

[0043] Hereinafter, a drum type washing machine according to an embodiment of the present invention will be described with reference to the drawings.

[0044] figure 1 It is a perspective view of the appearance of the drum-type washing machine of this embodiment, and Fig. 2 is a longitudinal sectional side view of the upper part. In this front-loading washing machine, the outer casing has a substantially circular corner between the upper portion 1a and the front portion 1b and has an inclined shape in which the front half is slightly curved outward (hereinafter referred to as "inclined portion 1c"). From the inclined portion 1c to the upper portion 1a behind it, there is a larger laundry input port 3, and the upper cover 2 for opening and closing the laundry input port 3, as shown in Figure 2, passes through shafts 2a, 2b extending horizontally. , it can be erected in a 2-fold state behind the laundry inlet 3.

[0045] The left side of the upper cover 2 is provided with a de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com