Wire electrode supply device for wire-cut electric discharge machine

A technology for supplying equipment and EDM wire, applied in electric machining equipment, electrode manufacturing, metal processing equipment, etc., can solve problems such as breakage, wire electrode relaxation, increase wire electrode tension, etc. effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

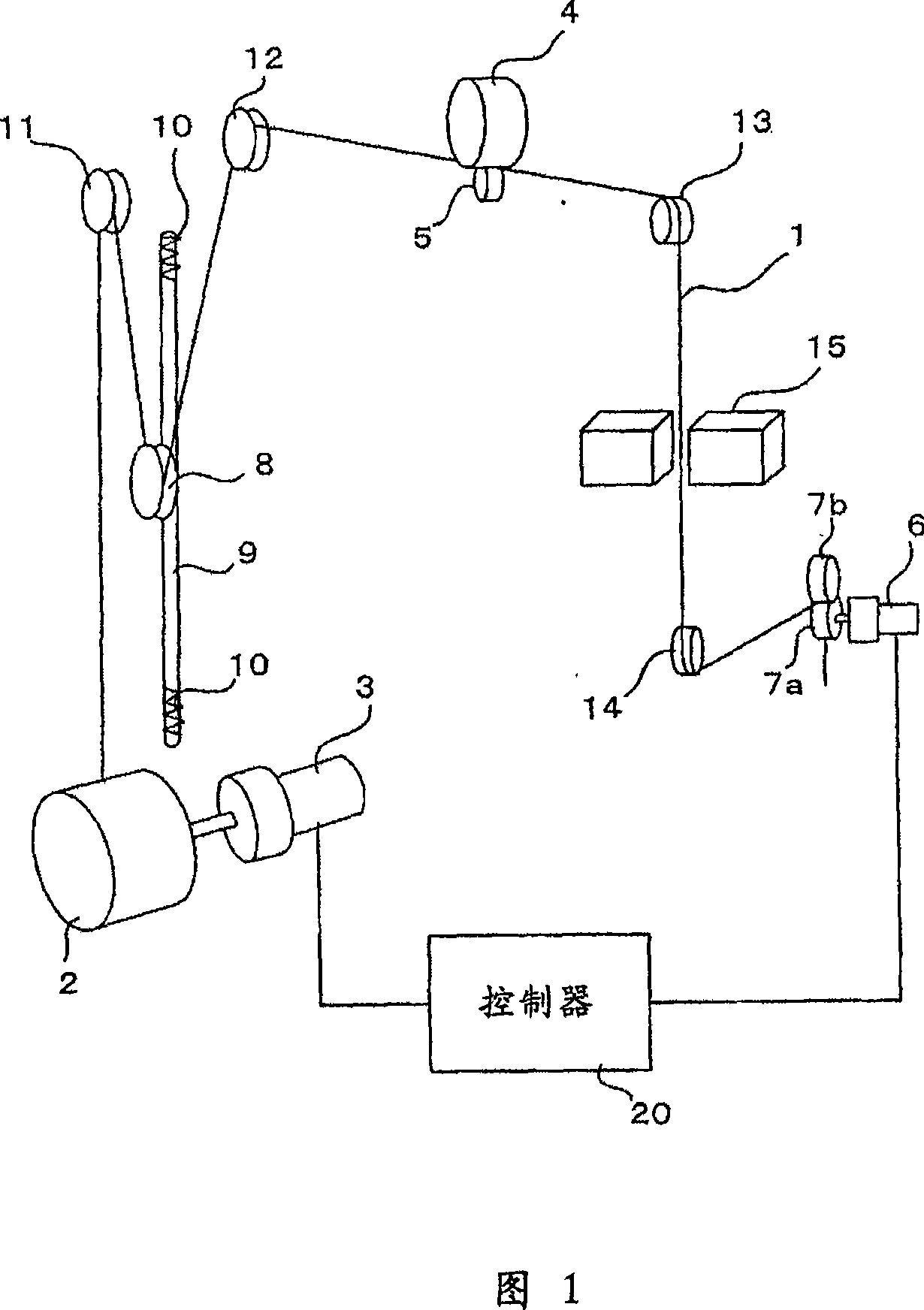

[0019] Referring to the drawings, a torque motor 3 is used to drive a bobbin 2 on which a wire electrode 1 is wound. The wire electrode 1 unrolled from the bobbin 2 passes through the roller 11, passes through the pulley 8, passes through the roller 12, passes between the brake roller 4 and the suppressor 5, and then passes through the roller 13 and passes through the working area of the workpiece 15, Passes between the roller 14 and the winding rollers 7a, 7b driven by the winding motor 6, and is wound up by the winding rollers 7a, 7b. The winding motor 6, the torque motor 3, and a not-shown brake device for driving the brake roller 4 are connected to and controlled by a controller 20 for controlling the wire electric discharge machine.

[0020] The pulley rises and falls along the guide 9. A spring 10 is provided at the end of travel of the pulley 8 in its upward and downward motions. When the pulley 8 reaches the end of its stroke, the spring 10 acts as a shock absorber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com