Collector, electrode structure, electricity storage component, and composition for collectors

A technology of current collectors and components, applied in the field of current collectors, can solve problems such as internal short circuit, external temperature rise, battery thermal damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

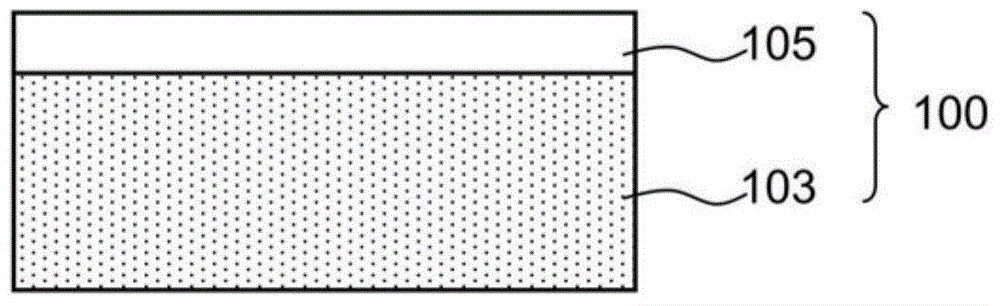

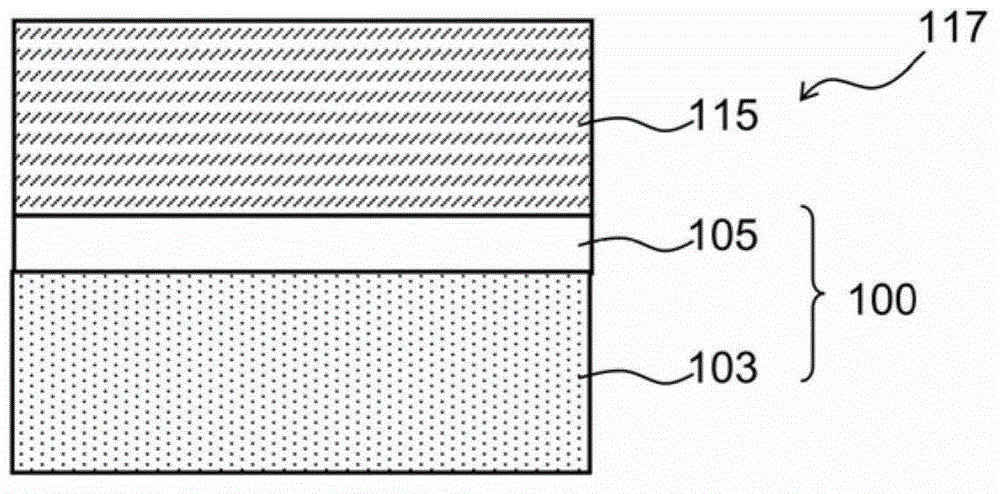

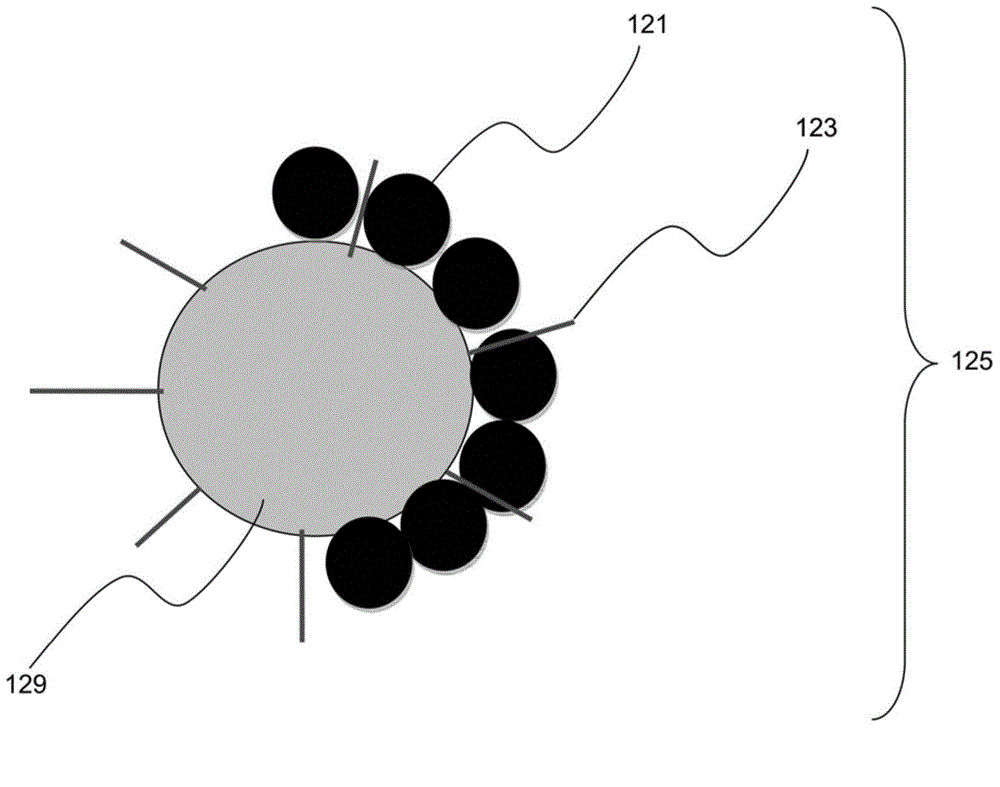

Embodiment 1

[0090] The latex-based polyolefin resin (polyolefin-based latex particles) shown in Table 1 is a water-based latex type maleic acid-modified polypropylene resin, and its mixing amount is 100 parts by mass. ) in an amount of 0.1 parts by mass, the two were mixed to obtain a resin solution, 25 parts by mass of acetylene black was mixed in the resin solution, and dispersed by a ball mill for 8 hours to make a coating. The resulting paint was coated on one side (Gravure coater) of an aluminum foil (JIS A1085) with a thickness of 15 μm by a gravure coater so that the coating film thickness was 2 μm (the weight of the coating film was 2 g / m 2 ). In order to make the film adhere, the substrate temperature (PMT) was heated to 110° C. for 24 seconds to produce a current collector electrode. Hereinafter, the substrate, coating, and drying conditions are the same as those in this embodiment, so the description will not be repeated.

Embodiment 2~16

[0092] The latex-based polyolefin resin (polyolefin-based latex particles) shown in Table 1 is a mixture of the following resins: (denatured by maleic acid) polypropylene (PP), (denatured by maleic acid) polyethylene (PE ) resin, (denatured by maleic acid) polyethylene-polypropylene (PE-PP) block polymerization (Block polymerization) resin, (denatured by maleic acid) polyethylene-polypropylene (PE-PP) graft Polymerization (Graft polymerization) resin, (by maleic acid denatured) polypropylene (PP) resin and (by maleic acid denatured) polyethylene (PE) resin. The mixing amounts of the various components are shown in Table 1, and a current collector electrode was produced in the same procedure as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com