Method and system for realizing standardized cooking by using intelligent temperature control

A cooking method and cooking container technology, applied in applications, cooking utensils, household utensils, etc., can solve problems such as process judgment errors, no temperature detection and feedback control, and affecting the quality of dishes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

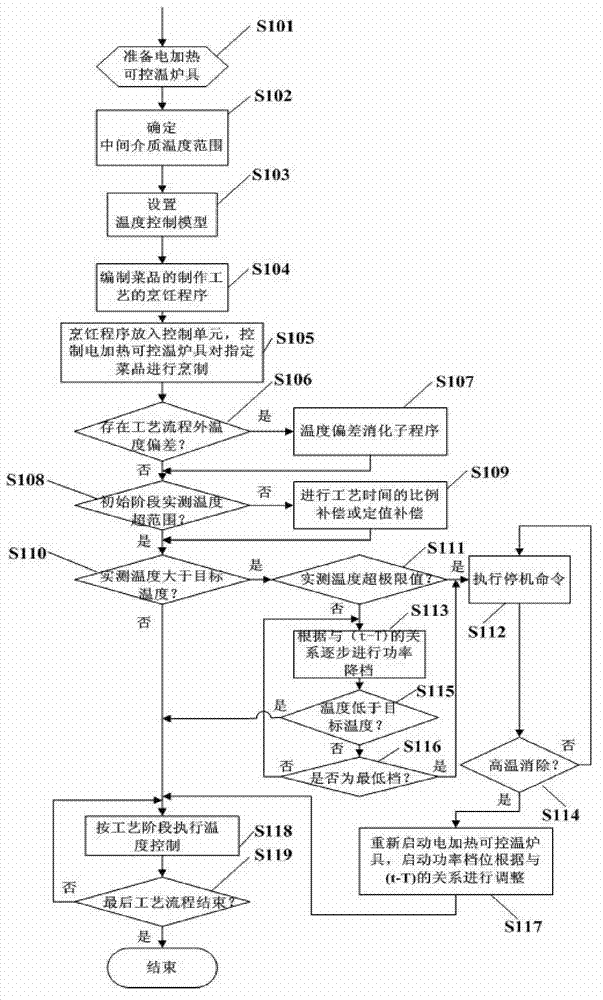

[0055] figure 1 A flowchart is shown. Its basic process is:

[0056] S101: Prepare an electric heating and temperature-controllable stove with a control unit;

[0057] S102: Determine the temperature range of the intermediate medium, wherein the water temperature is controlled within the range of 99-105 degrees Celsius; the oil temperature is controlled within the range of 170-250 degrees Celsius; the temperature of water-oil mixing is controlled within 135-135 degrees Celsius 170 degrees; the water vapor temperature is controlled at 100-110 degrees Celsius (under normal pressure), providing accurate temperature parameters for the cooking process of dishes;

[0058] S103: Set the temperature control model U=P-k(t-T), where P is the set power of the electric heating temperature-controllable stove (the target power at the time point), T is the target temperature, t is the measured temperature, and U is the electric heating controllable The actual execution power of the warm s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com