Colored filter with spacer, liquid crystal display device and method for making the same

A technology of color filter and manufacturing method, which is applied in the photoplate-making process, instruments, optics and other directions of the pattern surface, can solve the problems such as the uncontrollable distribution of LCD spacers, achieve brightness, avoid the influence of pixels, and improve Effects of Brightness and Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

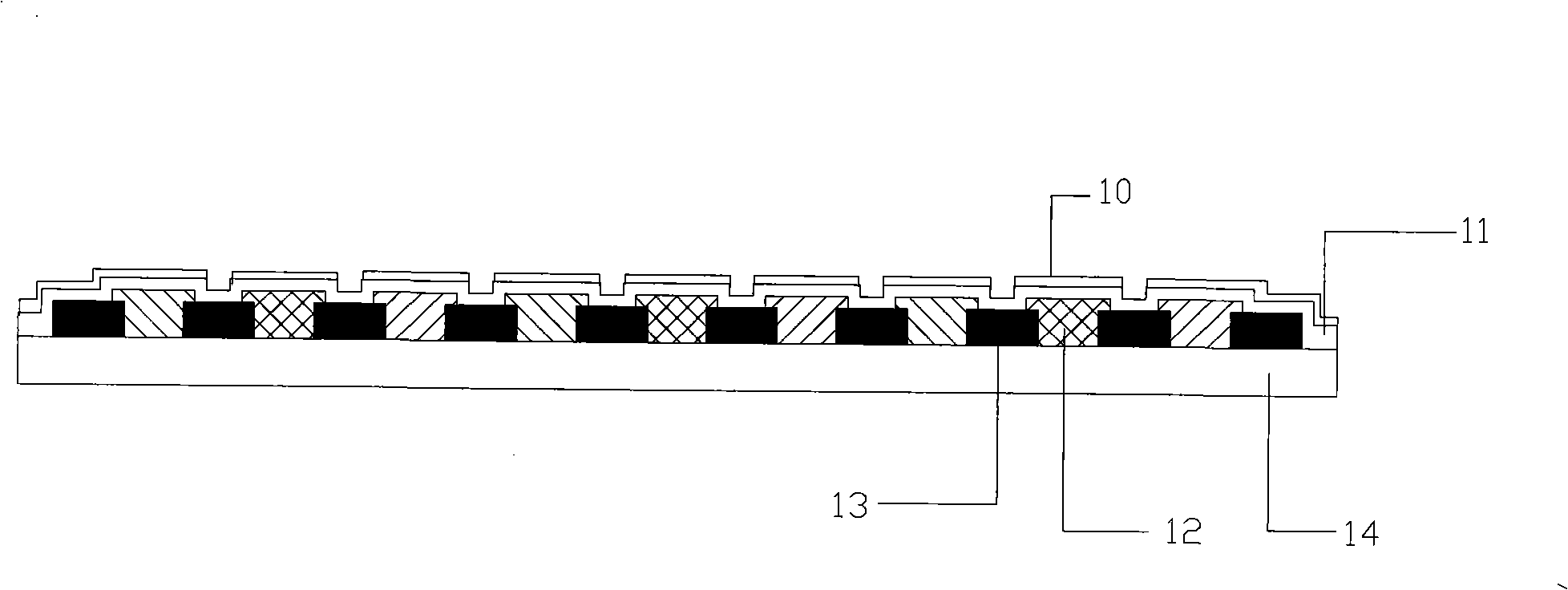

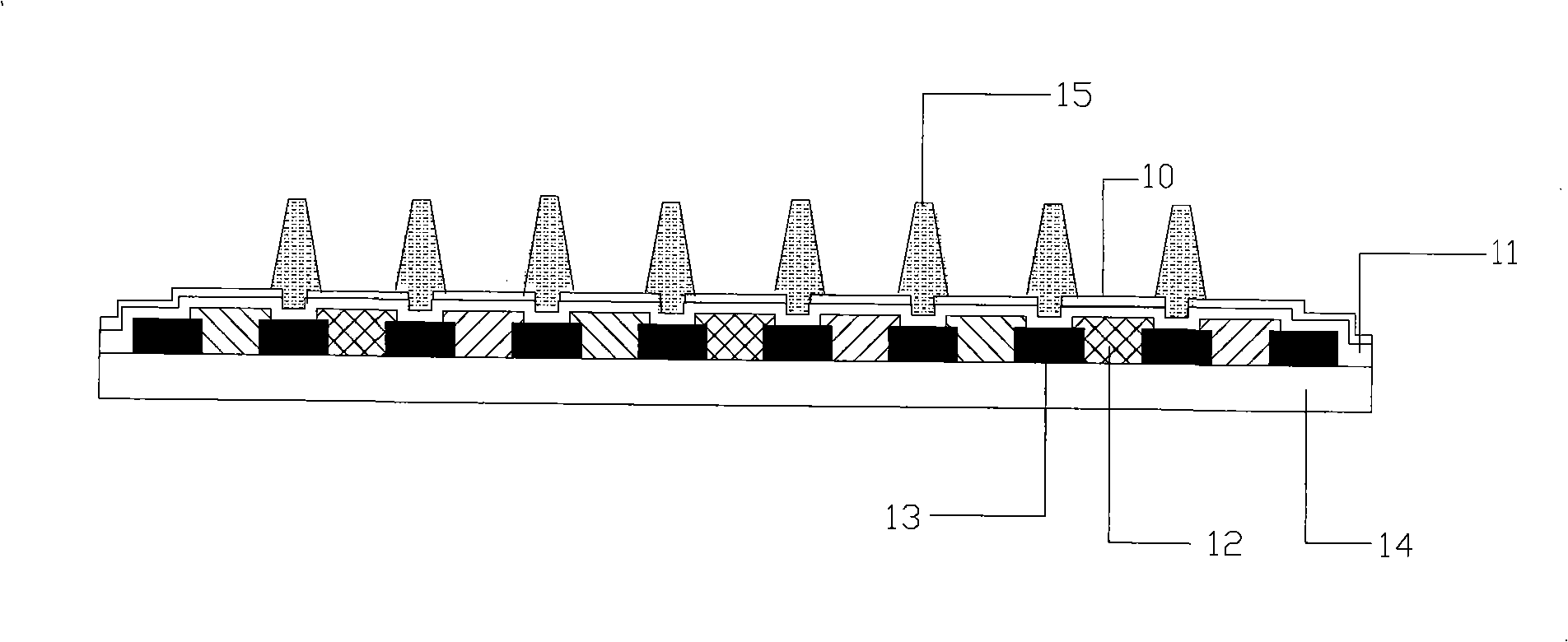

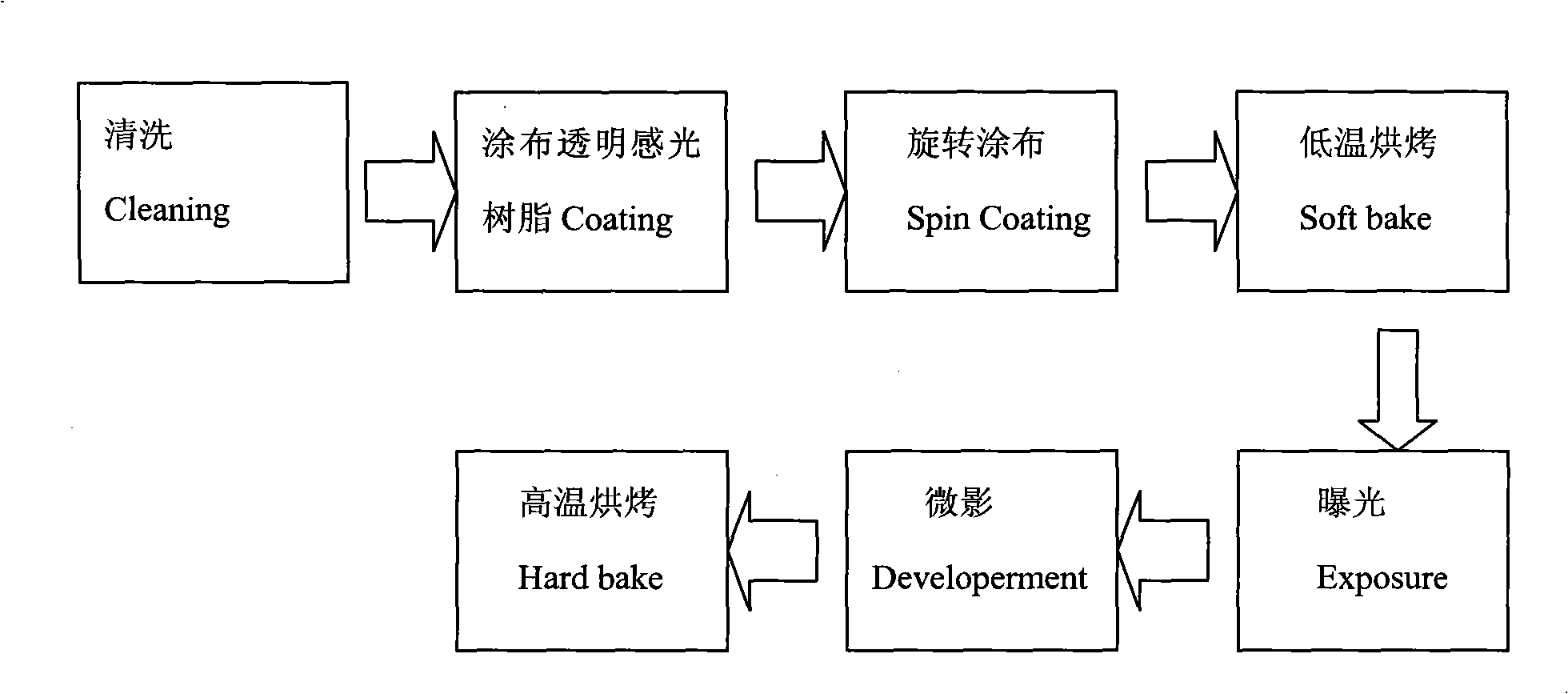

[0037] Embodiment 1. In this embodiment, spacers are formed on the top of the color filter substrate. The color filter substrate can use various existing color filters. The existing color filters are usually composed of A transparent SiO coated 2 On the glass substrate of the thin film, a black matrix for shading and a red film layer, a green film layer, a blue film layer arranged in a certain order and a transparent film layer for flattening and protecting the surface are arranged on the transparent substrate. Composition of flat layers. A typical existing color filter structure such as figure 1 shown, including a SiO-coated 2 The film is composed of a glass substrate 14, a black matrix layer 13, a color filter layer 12 including a plurality of color pixels, a flat layer 11, and an electrode layer 10 engraved with a pattern. The black matrix layer 13 is disposed on the surface of the glass substrate 14, and the black matrix layer is composed of horizontally and vertically ...

Embodiment approach 2

[0050] Embodiment 2 is different from Embodiment 1 in that the spacers are formed on the surface of the first substrate facing the color filter substrate. The first substrate can adopt various existing TFT substrates or white glass substrates, and the existing first substrates usually include a transparent SiO coated 2 The glass substrate of the thin film and the transparent electrode layer formed on the glass substrate adopt the manufacturing method in Embodiment 1, and the spacers are formed on the glass substrate and the transparent electrode layer through exposure and lithography. The position of the spacer is set so that the first substrate and the color filter are assembled to correspond to the area of the black matrix of the color filter, preferably the position of the spacer and the grid lines of the black matrix of the color filter Corresponds to the location area of the intersection point. After the first substrate and the color filter are assembled, the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com