Method for preparing porous titanium dioxide photocatalysis film with non-hydrolyzed sol-gel method

A technology of porous titanium dioxide and photocatalytic film, which can be applied in chemical instruments and methods, physical/chemical process catalyst, chemical/physical process, etc., and can solve the problems of unreported photocatalytic film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

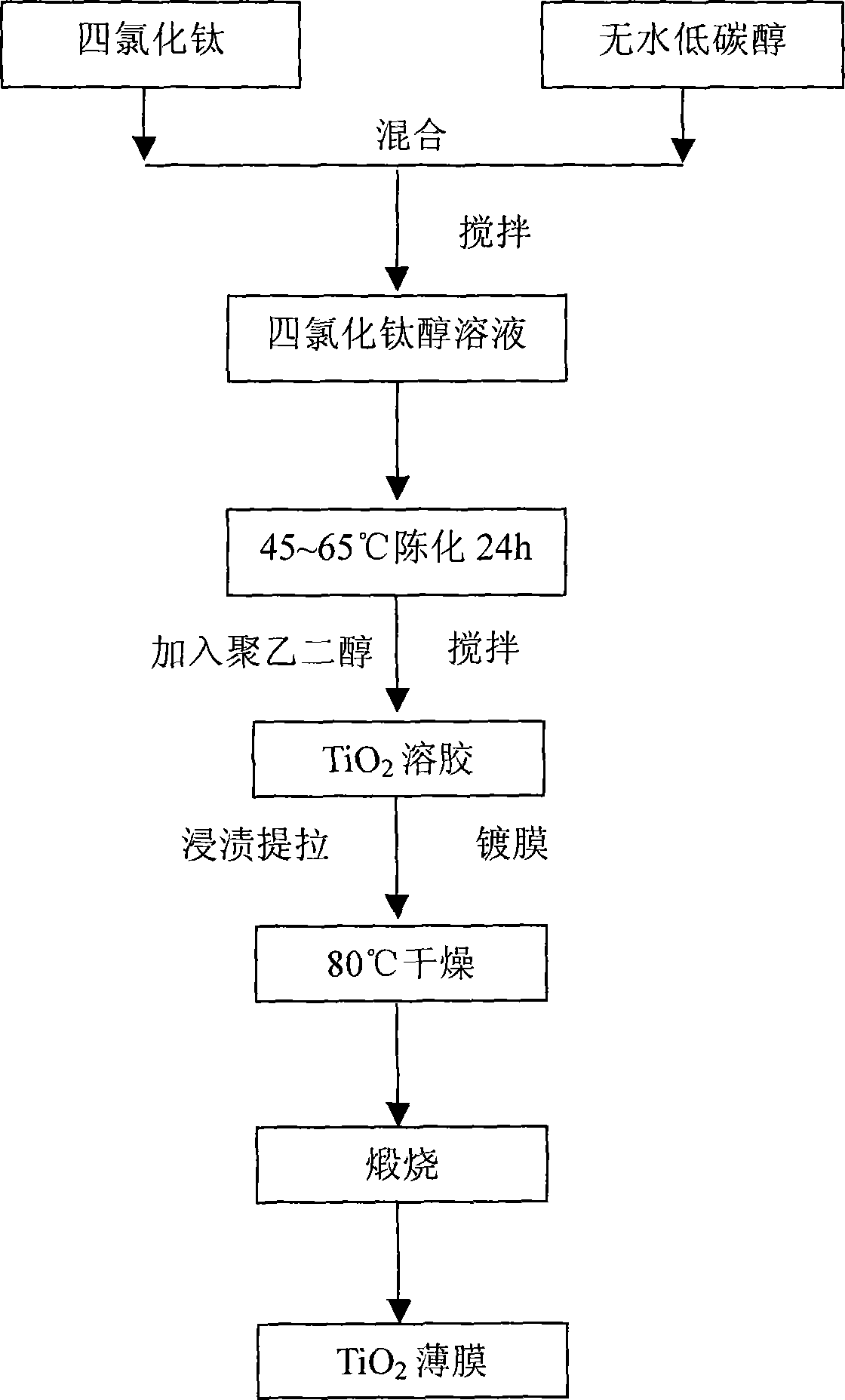

Image

Examples

Embodiment 1

[0019] In a fume hood, measure the required amount of absolute ethanol into a dry jar, place it in a cold water bath, use a pipette to transfer a certain amount of titanium tetrachloride and slowly mix with the ethanol, and stir thoroughly. Form TiCl 4 The ethanol solution has a molar concentration of 0.83mol / L. The ethanol solution of titanium tetrachloride was sealed and placed in an oven at 50°C for 24 hours, and then polyethylene glycol with a molecular weight of 1000 was added under stirring conditions, and the mixture was thoroughly stirred and mixed. The molar ratio of PEG1000 and titanium tetrachloride The ratio is 0.10, and finally the precursor sol is obtained and sealed and stored. At room temperature, in a dry environment, the immersion pulling method is used to coat the substrate with a pulling speed of 1mm / s, and then the film obtained by pulling is placed in an oven at 80°C for 2 hours to form TiO 2 Dry gel film. The dry gel film is calcined in an air atmosphere, th...

Embodiment 2

[0021] In a fume hood, measure the required amount of anhydrous isopropanol into a dry jar, place it in a cold water bath, use a pipette to transfer a certain amount of titanium tetrachloride and slowly mix with isopropanol , Stir fully to form TiCl 4 The isopropanol solution has a molar concentration of 0.43mol / L. The titanium tetrachloride isopropanol solution was sealed and placed in an oven at 45°C for 24 hours, and then a polyethylene glycol with a molecular weight of 600 was added under stirring conditions, and the mixture was thoroughly mixed. Among them, PEG600 and titanium tetrachloride The molar ratio is 0.20, and finally the precursor sol is obtained and sealed and stored. At room temperature, in a dry environment, the immersion pulling method is used to coat the substrate with a pulling speed of 1mm / s, and then the film obtained by pulling is placed in an oven at 80°C for 2 hours to form TiO 2 Dry gel film. Finally, the dry gel film is calcined in an air atmosphere wit...

Embodiment 3

[0023] In a fume hood, measure the required amount of anhydrous methanol into a dry jar, place it in a cold water bath, use a pipette to take a certain amount of titanium tetrachloride and slowly mix with methanol, and stir thoroughly. Form TiCl 4 The methanol solution has a molar concentration of 1.19mol / L. The methanol solution of titanium tetrachloride was sealed and placed in an oven at 55°C for 24 hours, and then polyethylene glycol with a molecular weight of 2000 was added under stirring conditions. The mixture was thoroughly stirred and mixed evenly. The molar ratio of PEG2000 and titanium tetrachloride The ratio is 0.02, and finally the precursor sol is obtained and sealed and stored. In a dry environment at room temperature, the dipping and pulling method is used to coat the substrate with a pulling speed of 1mm / s, and then the film obtained by pulling is placed in an oven at 80°C for 2 hours to form TiO 2 Dry gel film. The dry gel film is calcined in an air atmosphere, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com