Ultrahigh-strength TiCN-base Co-containing steel-bonded hard alloy threading tool capable of coating and preparation method

A technology of steel-bonded hard alloy and ultra-high strength, which is applied in the field of cobalt-containing and coatable TiCN-based steel-bonded hard alloy. Substrate high temperature resistance and other issues, to achieve the effect of improving sintering activity, improving tempering resistance, and increasing transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

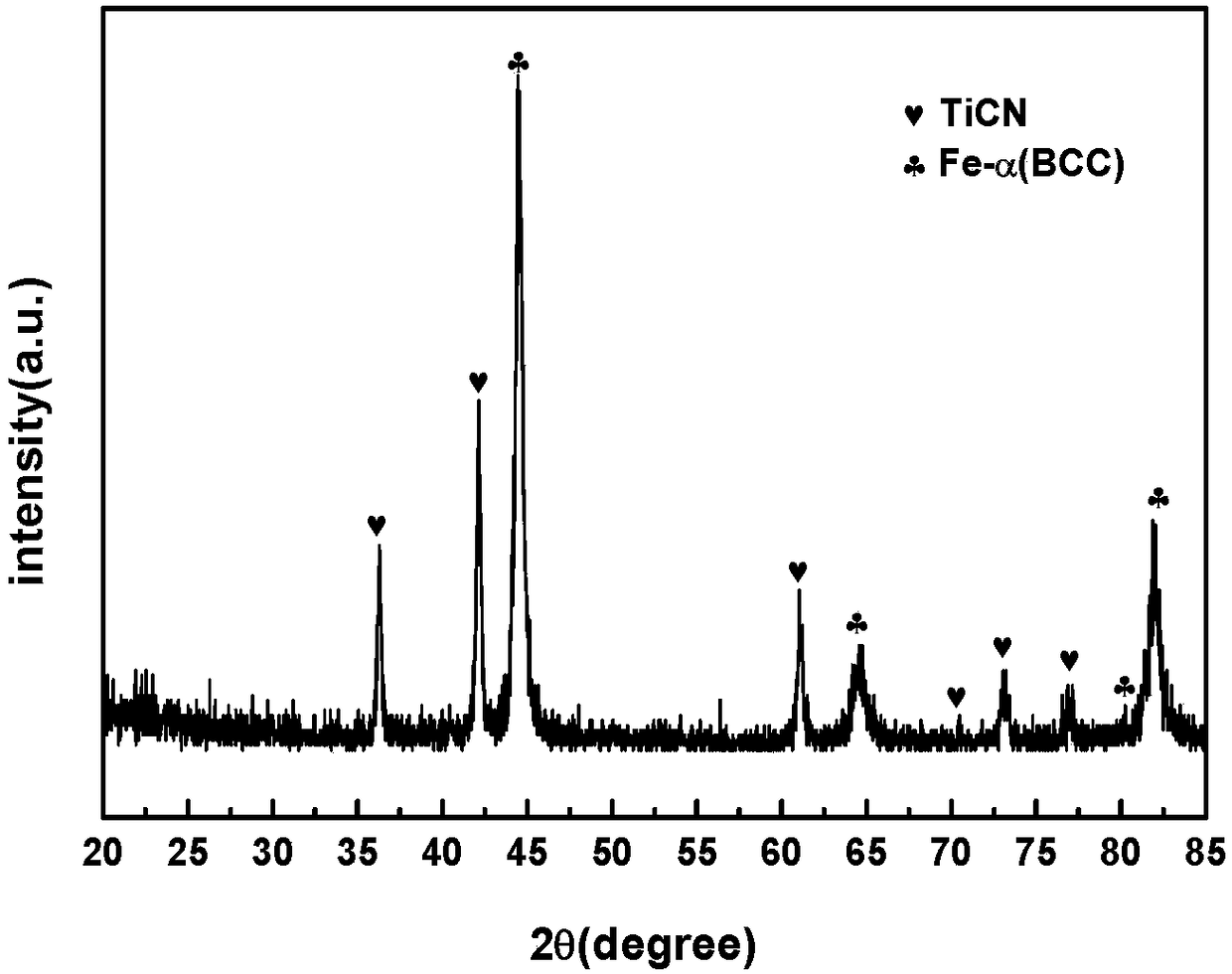

Embodiment 1

[0032] Present embodiment takes following technical scheme:

[0033] (1) 27wt.% titanium carbonitride powder, 0.90wt.% carbon powder, 2.0wt.% chromium carbide powder, 2.5wt.% molybdenum carbide powder, 2.0wt.% cobalt powder, 65.57wt .% iron powder and 5% of the total mass of paraffin were added to the stainless steel ball mill tank with a ball-to-material ratio of 5:1 and 100ml of absolute ethanol was added for wet milling and mixing. The speed of the ball mill was set at 250r / min, and the ball milling time was 72h;

[0034] (2) The powder obtained in step (1) is quickly dried in a vacuum drying oven by means of negative pressure drying, the drying temperature is 85 ° C, and the drying time is 4 hours, and then pre-conditioned for a certain time and temperature in a low oxygen partial pressure drying oven. Oxidation, passing through a 40-mesh sieve to sieve and granulate to obtain a mixed powder;

[0035] (3) Press the mixed powder of step (2) on a hydraulic press, the pressu...

Embodiment 2

[0040] (1) 30wt.% titanium carbonitride powder, 0.98%wt.% carbon powder, 3wt.% chromium carbide powder, 3wt.% molybdenum carbide powder, 5.0wt.% cobalt powder, 58.02wt. The remaining iron powder and 5% of the total mass of paraffin were added to the stainless steel ball mill tank, the ball to material ratio was 6:1, and 100ml of absolute ethanol was added for wet milling and mixing. The speed of the ball mill was set at 300r / min, and the ball milling time was 80h ;

[0041] (2) The powder obtained in step (1) is quickly dried in a vacuum drying oven by means of negative pressure drying, the drying temperature is 85 ° C, and the drying time is 4.5 hours, and then it is dried for a certain time and temperature in a low oxygen partial pressure drying oven. Preoxidation, passing through a 40-mesh sieve and granulating to obtain mixed powder;

[0042] (3) Press the mixed powder of step (2) on a hydraulic press, the pressure is 150Mpa, the pressure is increased slowly, and the pres...

Embodiment 3

[0047] (1) 32wt.% titanium carbonitride powder, 1.1%wt.% carbon powder, 2.8wt.% chromium carbide powder, 3.5wt.% molybdenum carbide powder, 7.0wt.% cobalt powder, 53.6 The balance of wt.% iron powder and 5% of the total mass of paraffin were added to the stainless steel ball mill tank, the ratio of ball to material was 5:1, and 100ml of absolute ethanol was added for wet grinding and mixing. The speed of the ball mill was set at 280r / min, and the ball mill Time 96h;

[0048] (2) The powder obtained in step (1) is quickly dried in a vacuum drying oven by means of negative pressure drying, the drying temperature is 80 ° C, and the drying time is 4 hours, and then pre-conditioned for a certain time and temperature in a low oxygen partial pressure drying oven. Oxidation, passing through a 40-mesh sieve to sieve and granulate to obtain a mixed powder;

[0049] (3) Press the mixed powder of step (2) on a hydraulic press, the pressure is 100Mpa, the pressure is increased slowly, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com