Hypoxic fire prevention and fire suppression systems and breathable fire extinguishing compositions for human occupied environments

a technology of breathable fire extinguishing compositions and fire prevention and fire suppression systems, which is applied in the direction of lighting and heating apparatus, heating types, separation processes, etc., can solve the problems of system only being deployed post-combustion, ozone depletion, toxic and environmentally unfriendly,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

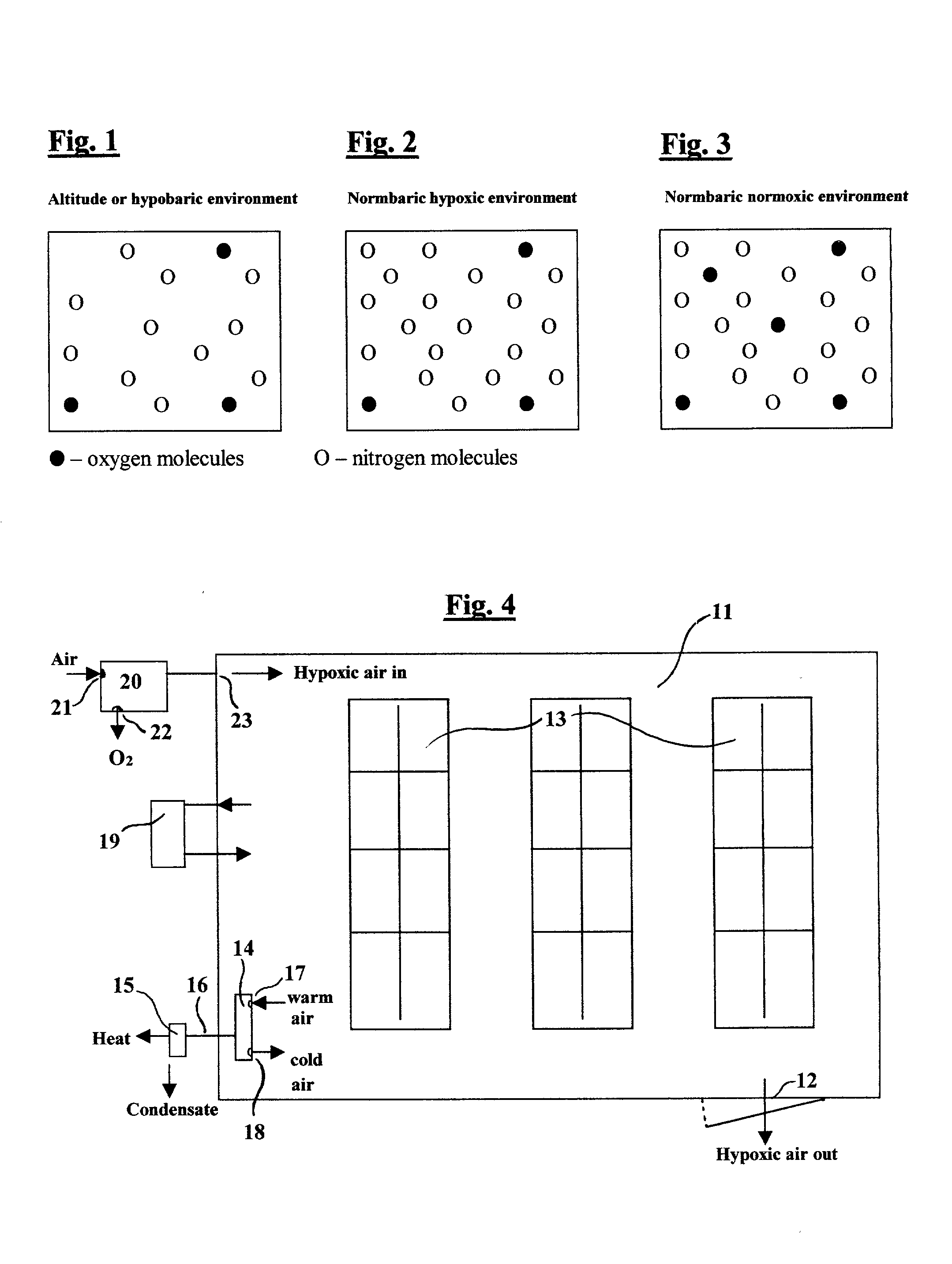

[0064] This invention is based on a discovery made during research conducted in a Hypoxic Room System manufactured by Hypoxico Inc. The inventor discovered that that the processes of ignition and combustion in a normbaric, hypoxic environment are far different from the ignition and combustion process that occurs in a hypobaric or natural altitude environment with the same partial pressure of oxygen.

[0065] For example, air with a 4.51" (114.5 mm of mercury) partial pressure of oxygen at an altitude of 9,000' (2700 m) can easily support the burning of a candle or the ignition of paper.

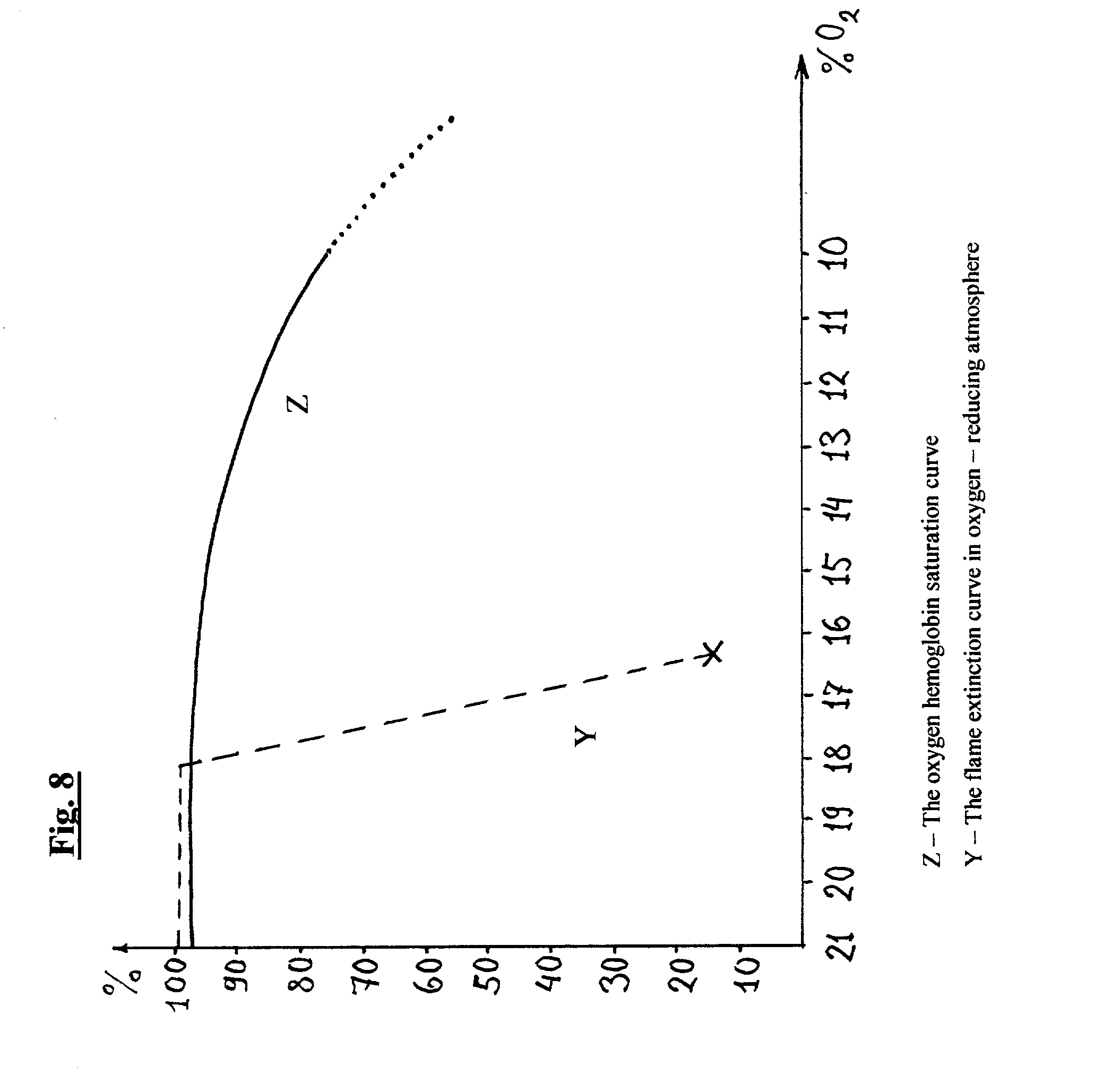

[0066] However, if we create a corresponding normbaric environment with the same partial pressure of oxygen (4.51"or 114.5 mm of mercury), a candle will not burn and paper will not ignite. Even a match will be instantly extinguished after the depletion of the oxygen-carrying chemicals found at its tip. For that matter, any fire that is introduced into this normbaric, hypoxic environment is instantly exti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com