Snowmobile with improved drive train

A technology for motor vehicles and drive trains, applied to drive trains. Fields, can solve problems such as wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

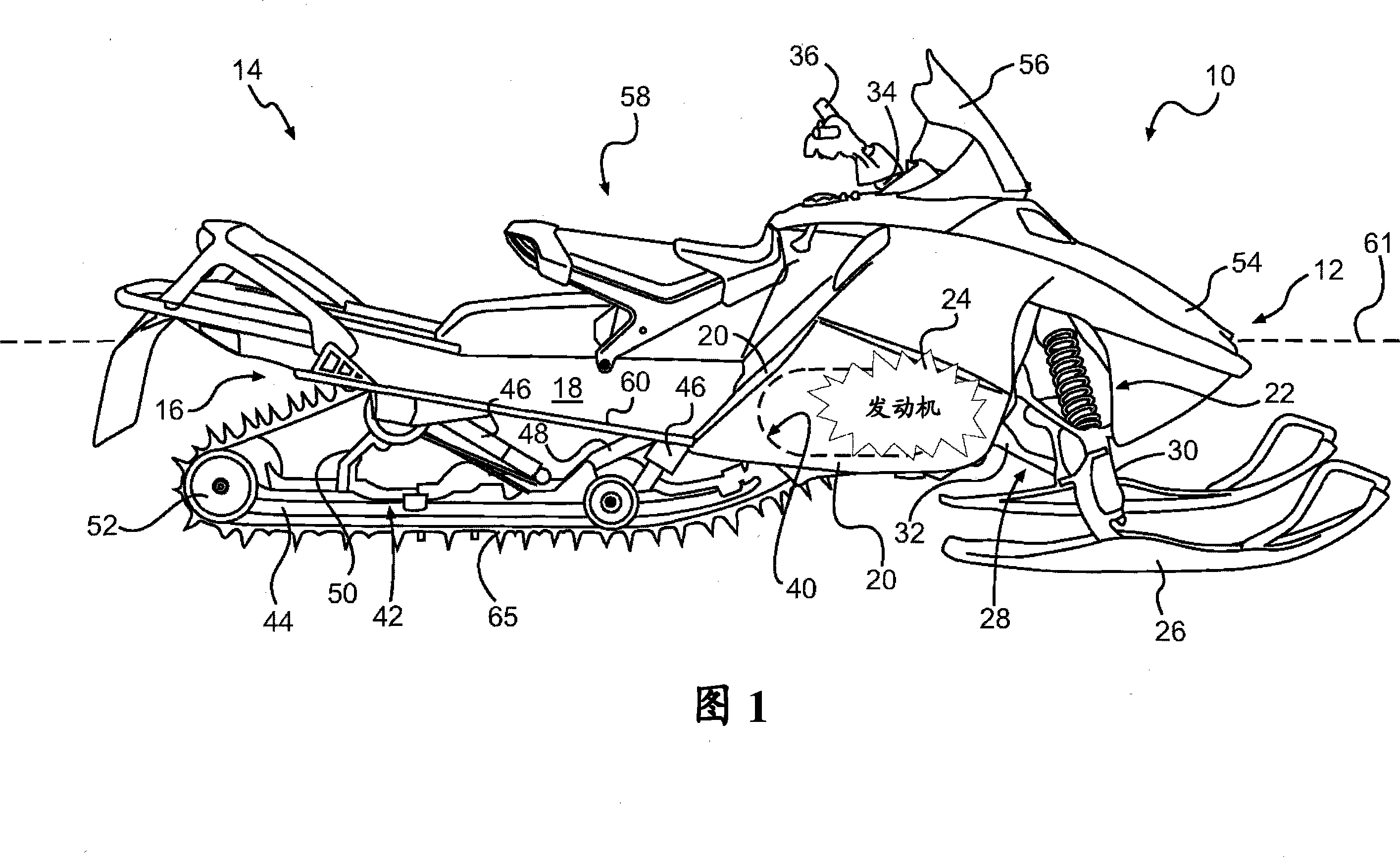

[0027] Referring now to FIG. 1 , a snowmobile incorporating an embodiment of the present invention is generally indicated at 10 . A particular application of the invention relates to snowmobiles, although certain aspects of the invention are applicable to other types of vehicles.

[0028] The snowmobile 10 includes a front end 12 and a rear end 14 defined in line with the direction of travel of the vehicle. The snowmobile 10 includes a frame 16 that generally includes a tunnel 18 , an engine mount portion 20 and a front suspension assembly portion 22 . Channel 18 is generally constructed of an inverted U-shaped bent metal sheet that extends rearwardly along the longitudinal axis of snowmobile 10 and connects to engine mount portion 20 at the front. An engine 24 , shown schematically in FIG. 1 , is supported by the engine mount portion 20 of the frame 16 . At the front end 12 of the snowmobile 10 is provided a steering assembly (not labeled) on which two skis 26 are positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com