Tray piston swing pressure fluid feeding machine driven by crank-link mechanism

A technology of crank connecting rod mechanism and fluid machine, which is applied in the direction of swing piston type machinery, machine/engine, swing piston type pump, etc., can solve the problem of not finding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

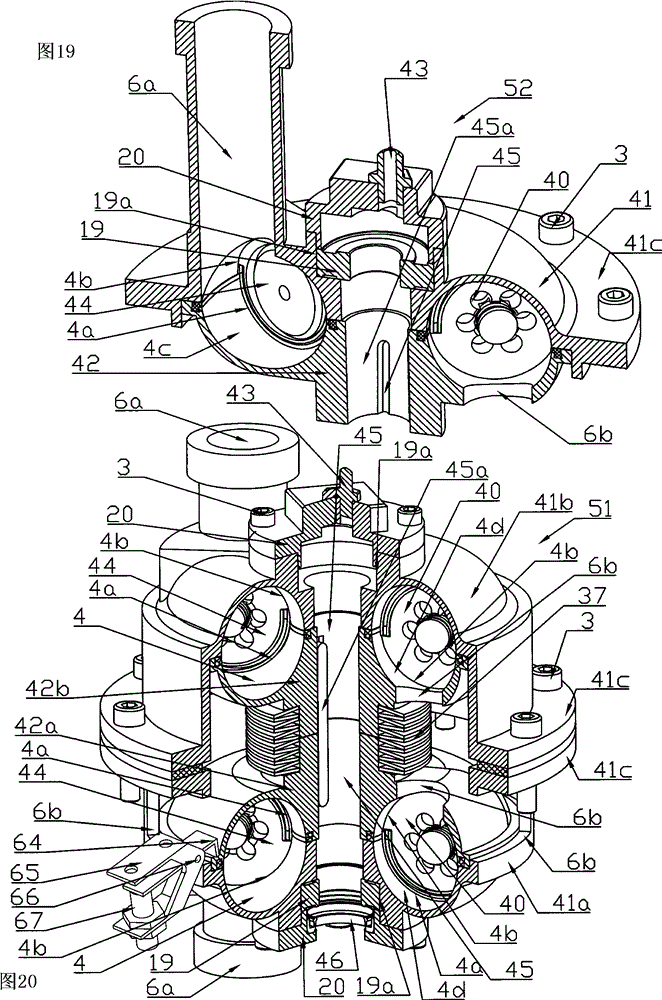

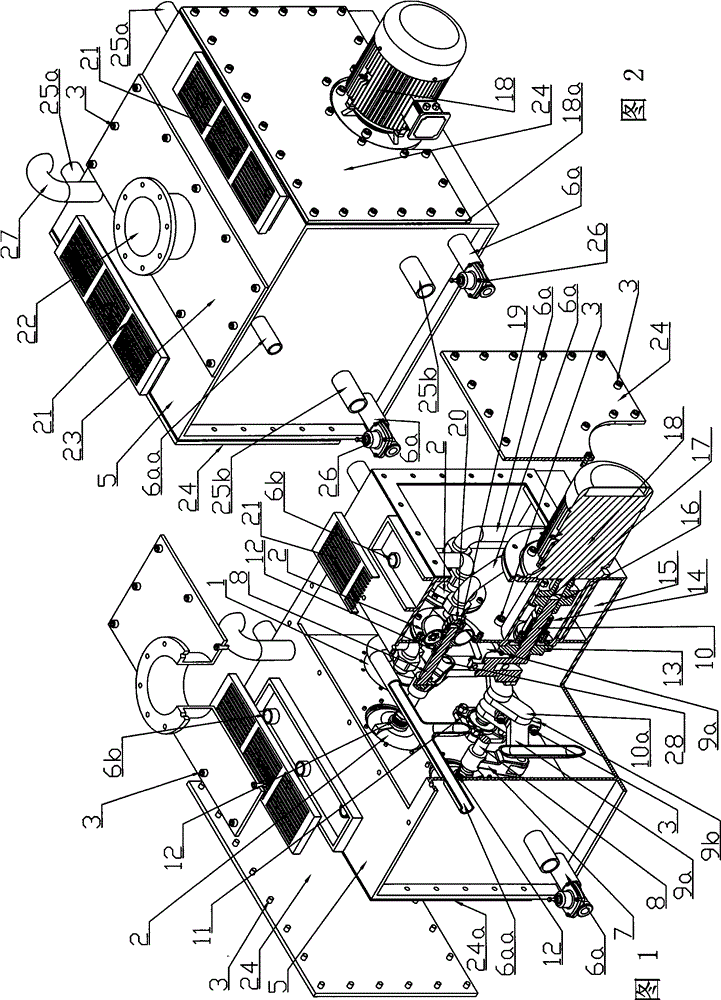

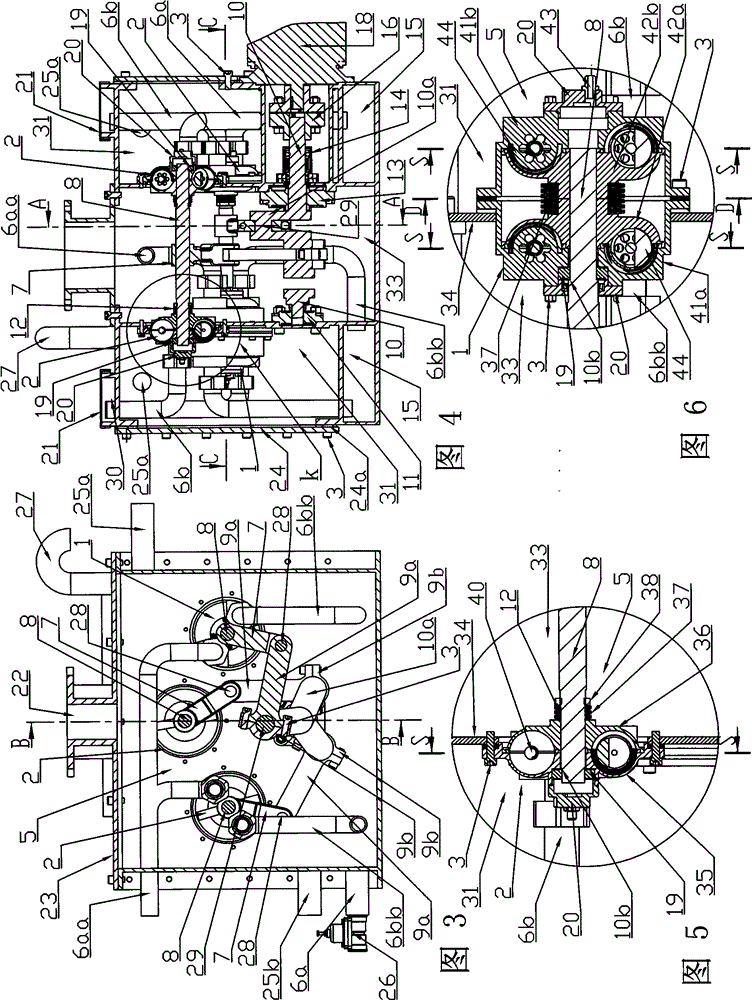

[0066] A pallet piston rocking press-feeding fluid machine driven by a crank-link mechanism, including a support shell 5, several pallet piston rocking actuators, a fluid inlet and outlet channel system, a cooling system, and a driving force generating system; the fluid inlet and outlet channel system includes Fluid passages, nozzles and valves, the fluid passages communicate with the working chamber 4c; the cooling system is a mechanism for forced cooling and / or natural heat dissipation of the components of the pressurized fluid machine; the pallet piston swing actuator includes 1 or 2 Fixed rocking tray group, piston piece, connecting mechanism, power entry and exit bonding structure, lubrication system and sealing structure; The pallet piston swing actuator A of the single solid rocking pallet group, the basic prototype of the device is the general embodiment 6 in the application numbers CN201410058100.X and 210420073755.X of "Pallet Piston Swing Drive Machine with Mechanica...

Embodiment 2

[0085] The difference between this embodiment 2 and embodiment 1 is in the following points, and all the other are basically the same as embodiment 1:

[0086] 1. In this embodiment 2, there are two types of pallet piston swing actuators, one of which is a pallet piston swing actuator B with a single solid rock pallet group using a fixed rock pallet group. The basic prototype of this device is " The overall embodiment 5 in the application numbers CN201410058100.X and 210420073755.X of the mechanically driven piston acting on the fluid load of the tray piston type swing driver; the second is the pair of clamp split swing tray piston type swing using two solid rocking tray groups Executing device B, the basic prototype of which is the general embodiment 5 in the application number CN201410092640.X and 201420114474.4 of "Piston Swing Drive Machine for Wafer Swing Tray Acting on Fluid with Mechanically Driven Piston";

[0087] 2. The crank-connecting rod transmission group is a cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com