Mobile counterweight type pumping unit

A technology of counterweight and pumping unit, which is applied in the direction of machine/engine, liquid variable capacity machinery, mechanical equipment, etc., can solve problems such as energy waste, and achieve the effect of energy saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

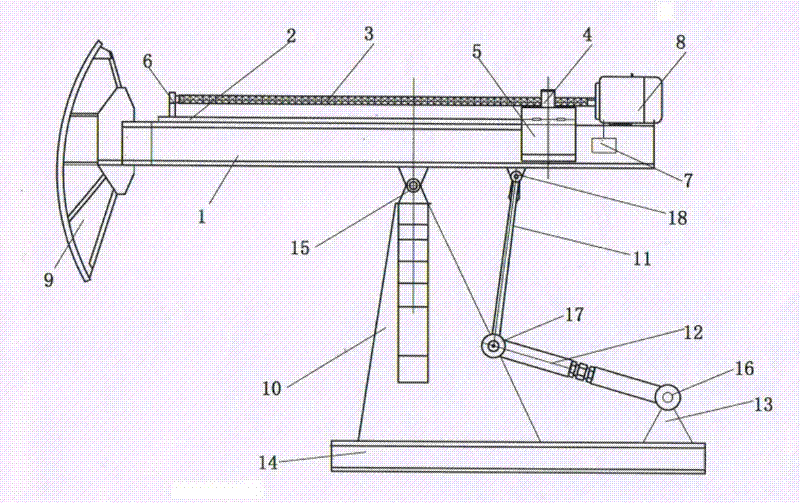

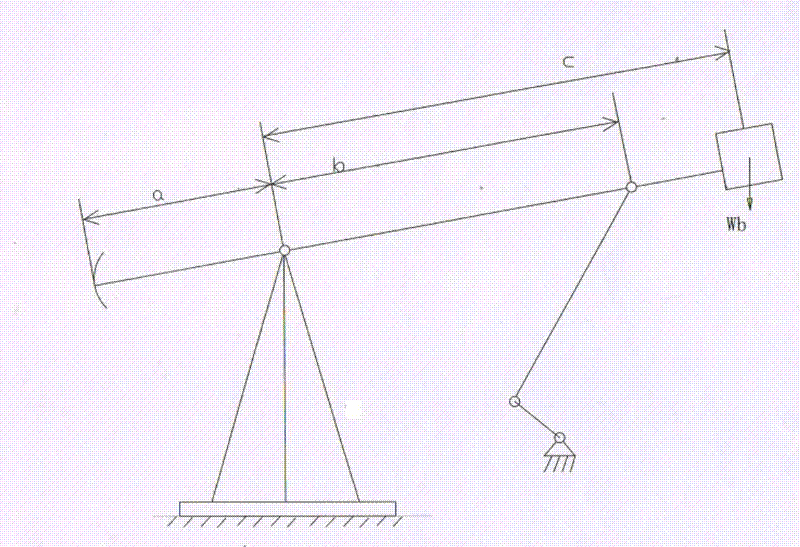

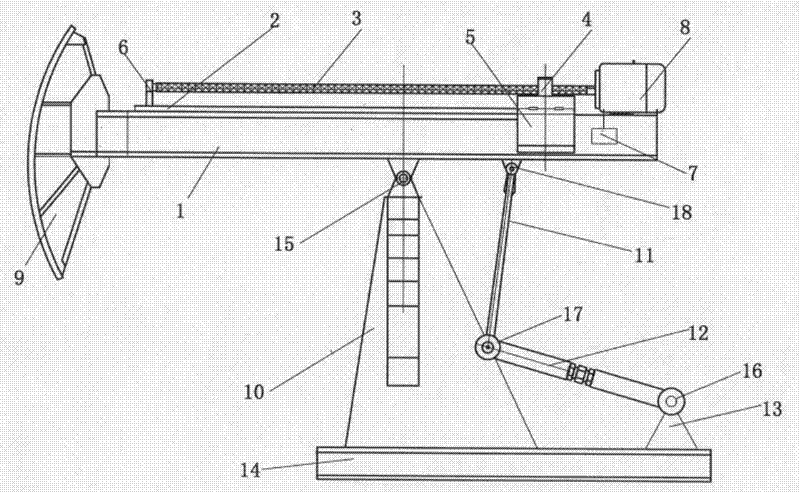

[0055] The mobile counterweight type pumping unit comprises a counterweight type balance mechanism, a tripod 10, a crank link mechanism and a frame 14.

[0056] The counterweight type balance mechanism includes a beam 1, two identical slideways 2, a reciprocating lead screw 3, two identical counterweights 5, a variable frequency motor 8 and a donkey head 9.

[0057] The frequency conversion motor 8 is fixed on the right side of the upper end face of the beam 1, and the frequency conversion motor 8 is connected with the reciprocating wire through the shaft coupling.

[0058] -3-

[0059] The right end of bar 3 is connected, and the left end of reciprocating leading screw 3 is supported on the left side of the upper end surface of swimming beam 1 by leading screw support 6 . Slideways 2 are respectively fixed on both sides of the beam 1 .

[0060] A screw nut 4 is installed on the reciprocating lead screw 3, and two identical counterweights 5 are fixed on the screw nut 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com