Mining motor belt pulley automatic disassembly press machine

A technology of automatic disassembly and motor use, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, manual operation, and low productivity, and achieve the goals of reducing labor intensity, wide application range, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

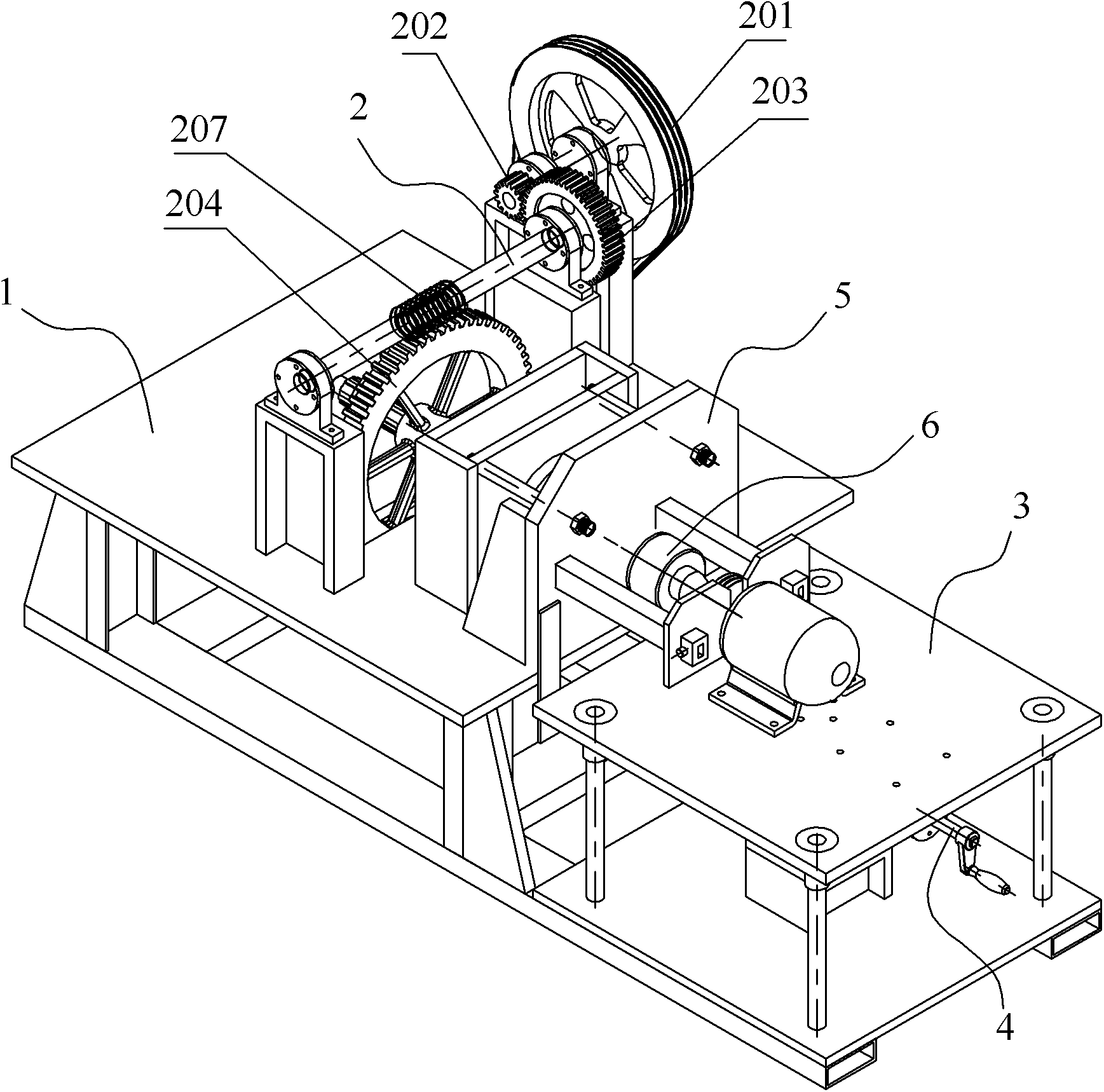

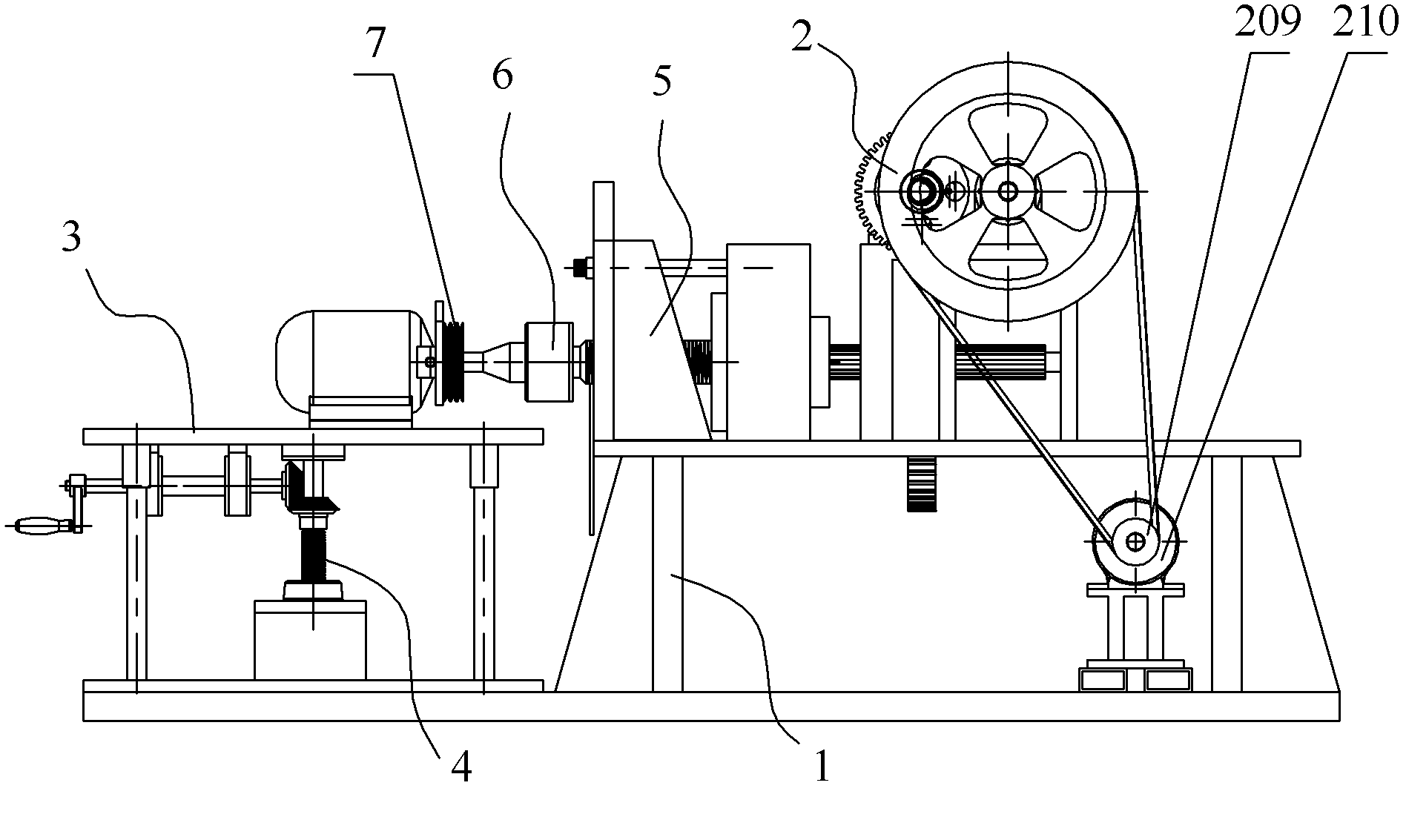

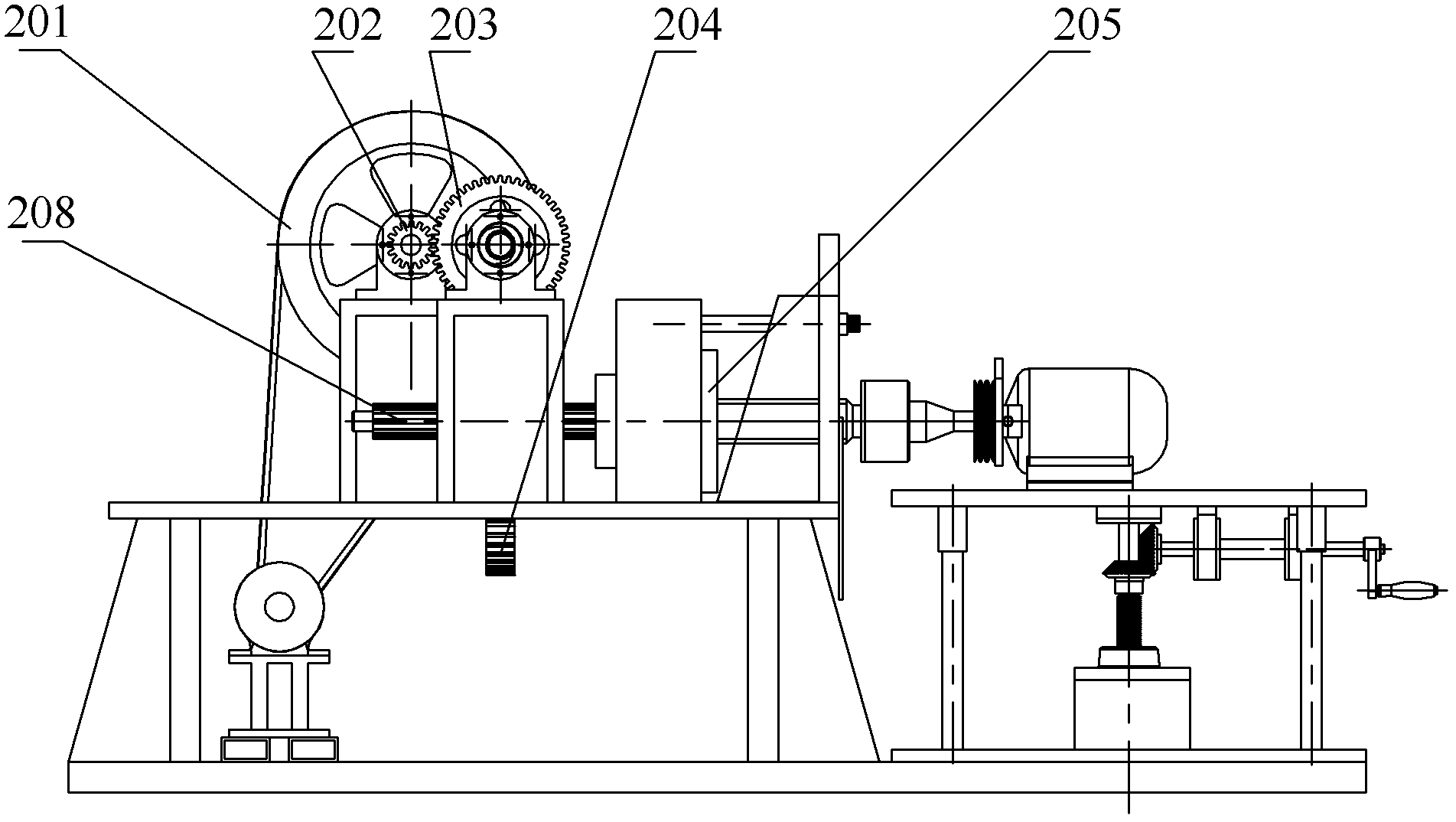

[0038] A mining motor pulley automatic dismantling press, such as Figure 1-Figure 4 As shown, it includes a frame 1, a main transmission mechanism 2, an elevating workbench 3, a workbench elevating mechanism 4, a card wheel bracket 5, and a quick-change ejector component 6.

[0039] rack 1 as described (see Figure 5-Figure 6 ) is a frame structure mainly composed of rack panels 101, 4 columns 108, 2 bottom beams 106, 4 beams 105 and 4 reinforcement plates 107. The 2 bottom beams pass through 4 columns and 4 reinforcement plates respectively Connected with the frame panel, the 4 beams are respectively installed between the 2 bottom beams, and the frame panel is respectively equipped with 2 transmission shaft I mounting supports 103, 2 worm screw mounting supports 102 and 1 main transmission The nut mounting base 104, two motor mounting base fixing beams 110 are installed on the bottom beam, and the motor mounting base fixing beam 110 is fixed with a motor mounting base 109. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com