Steel belt type dryer

A belt dryer and dryer technology, applied in the field of mechanical devices, can solve the problems of difficulty in arranging paste-like, viscous materials and fine materials, unsolvable deviations, and difficulty in uniform distribution of viscous materials, so as to achieve uniform cloth thickness. The effect of easy control, favorable deviation correction and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

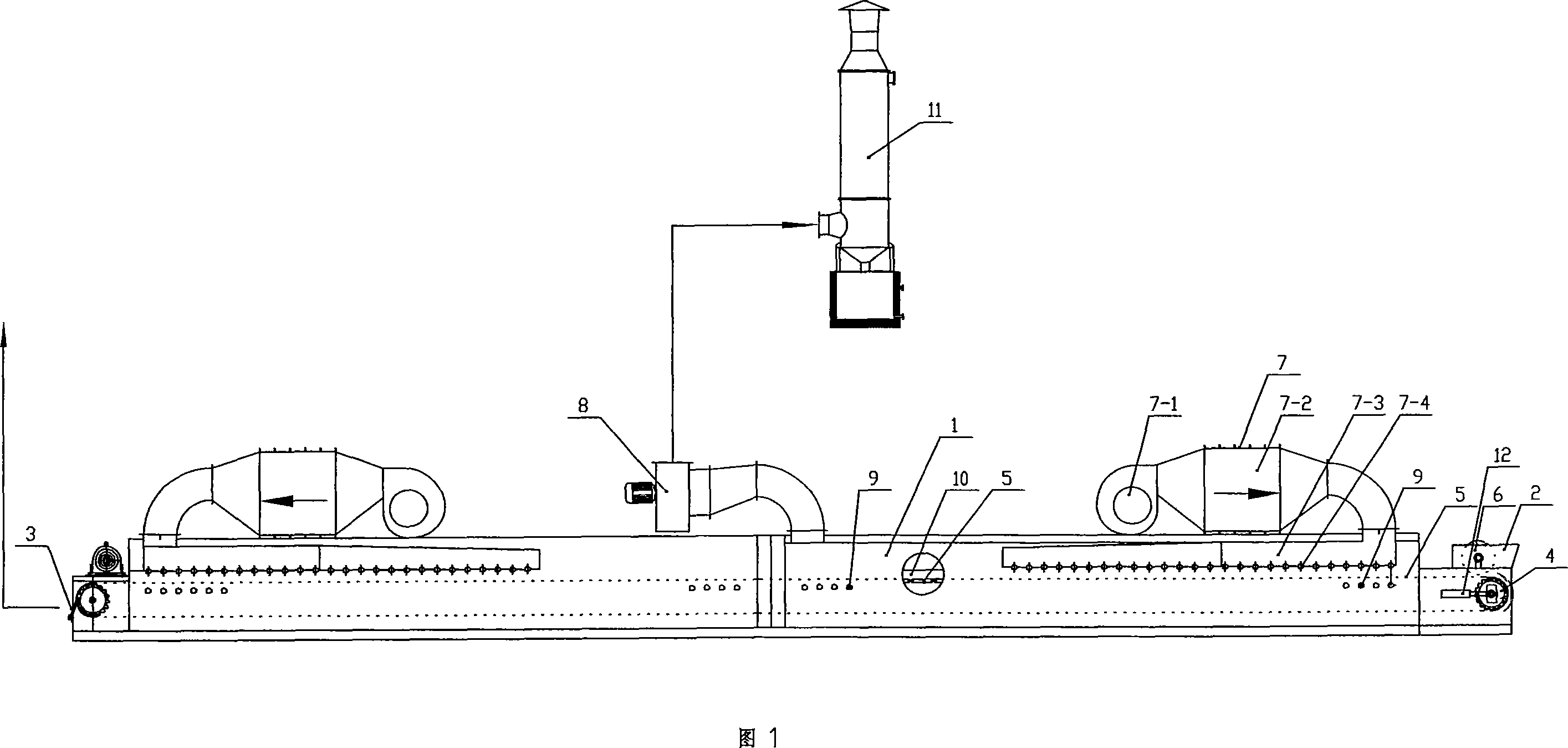

[0014] As shown in Figure 1, a belt dryer has a drying channel 1, a feed port 2 and a discharge port 3 are respectively arranged at both ends of the drying channel 1, and a driving wheel driven by a driving wheel 4 is arranged in the drying channel 1. Conveyor belt 5, the conveyor belt 5 is a stainless steel belt, baffles 10 are provided on both sides of the conveyor belt 5, and a deviation correcting device 12 for correcting the left and right deviation of the conveyor belt 5 when it is advanced is provided at the driving wheel 4. A material distribution device 6 is provided at the feeding port 2, and a gas heating device 7 and a dehumidification blower 8 are connected to the drying channel 1, and a dust removal device 11 connected thereto is provided above the dehumidification blower 8. The material distributing device 6 is a rubber or silicon rubber cloth pressing roller, and the gas heating device 7 is composed of a blower 7-1, a heat exchange sheet 7-2 and an air distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com