Modular closed-type multifunctional mechanical drive testing stand

A technology of multifunctional machinery and transmission test bench, which is applied in the field of mechanical transmission, can solve the problems of uneconomical use and bulky structure of energy-consuming devices, and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the purpose and advantages of the present invention, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

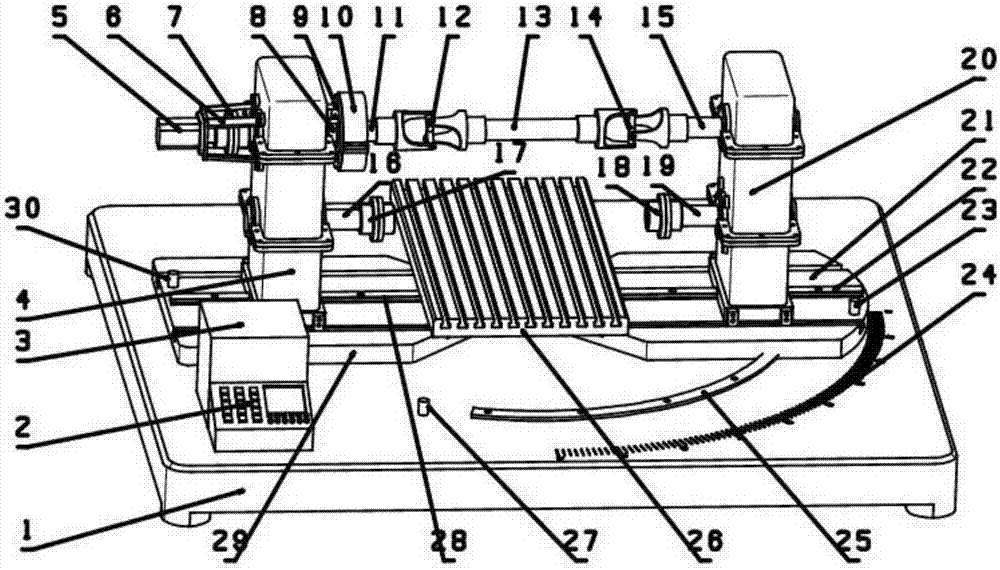

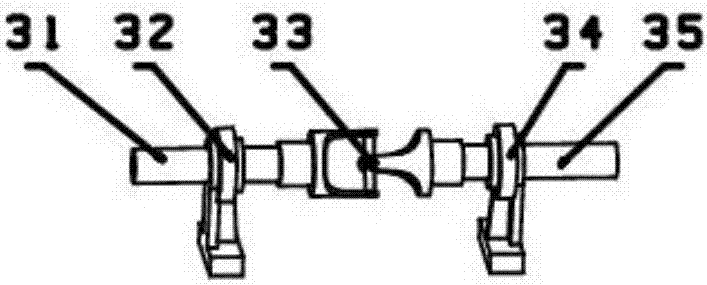

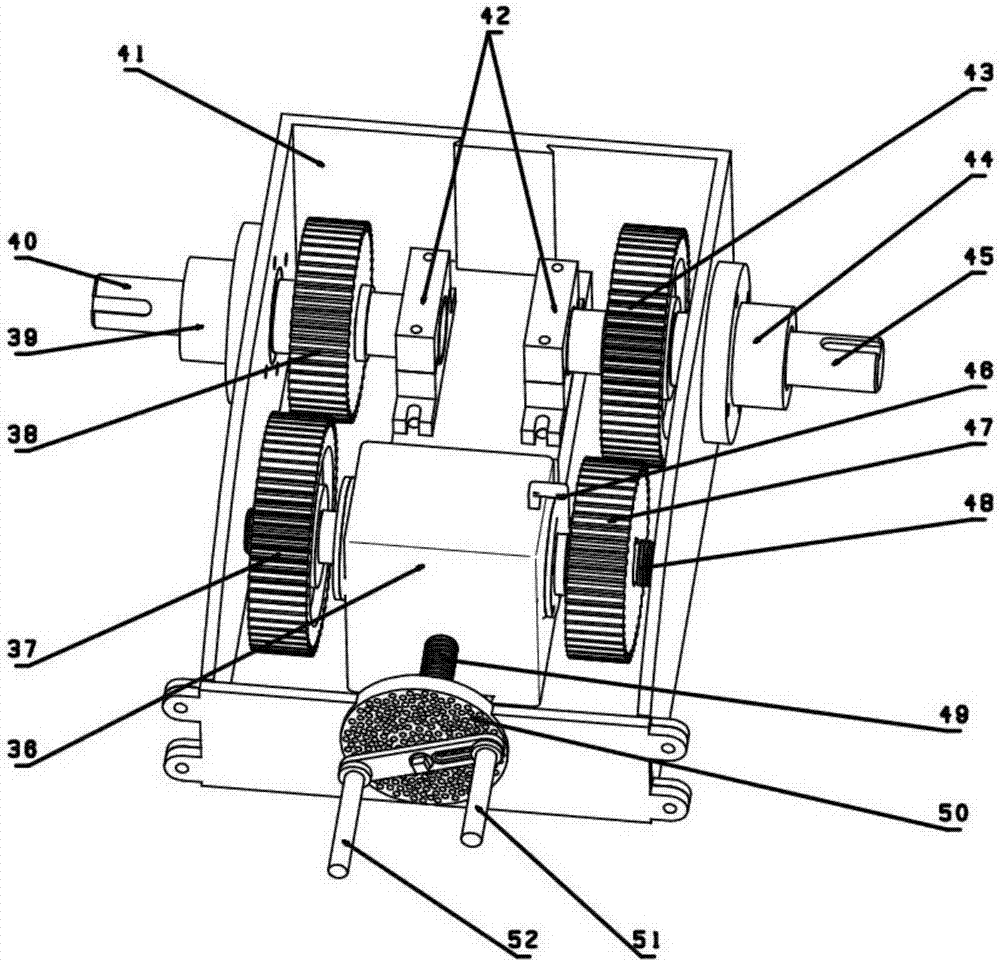

[0029] Such as figure 1 , 2 , 3, 4, 5, and 6 show the modular closed multifunctional mechanical transmission test bench, including: base 1, operation panel 2, processor 3, vertical reducer I 4, servo motor 5, motor support frame 6, Motor coupling 7, gear shaft Ⅰ 8, loader mounting frame 9, loader 10, connecting shaft Ⅰ 11, universal coupling Ⅰ 12, connecting optical shaft 13, universal coupling Ⅱ 14, gear shaft Ⅱ 15, gear shaft Ⅲ 16 , coupling Ⅰ17, coupling Ⅱ18, gear shaft Ⅳ19, vertical reducer Ⅱ20, rotating disc 21, linear slide rail Ⅰ22, limit block Ⅰ23, scale 24, ring guide rail 25, mounting plate 26, limit block Ⅱ27, linear slide rail Ⅱ28, fixed plate 29, limit block Ⅲ30, connecting shaft Ⅱ31, magnetic fixed sensor Ⅰ32, test couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com