Autonomous-dispatch system linked to mine development plan

a technology of autonomous dispatch and mine development, applied in the field of mining systems, can solve the problems of easy errors, difficult to recognize and correct, and prevent the economic extraction of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

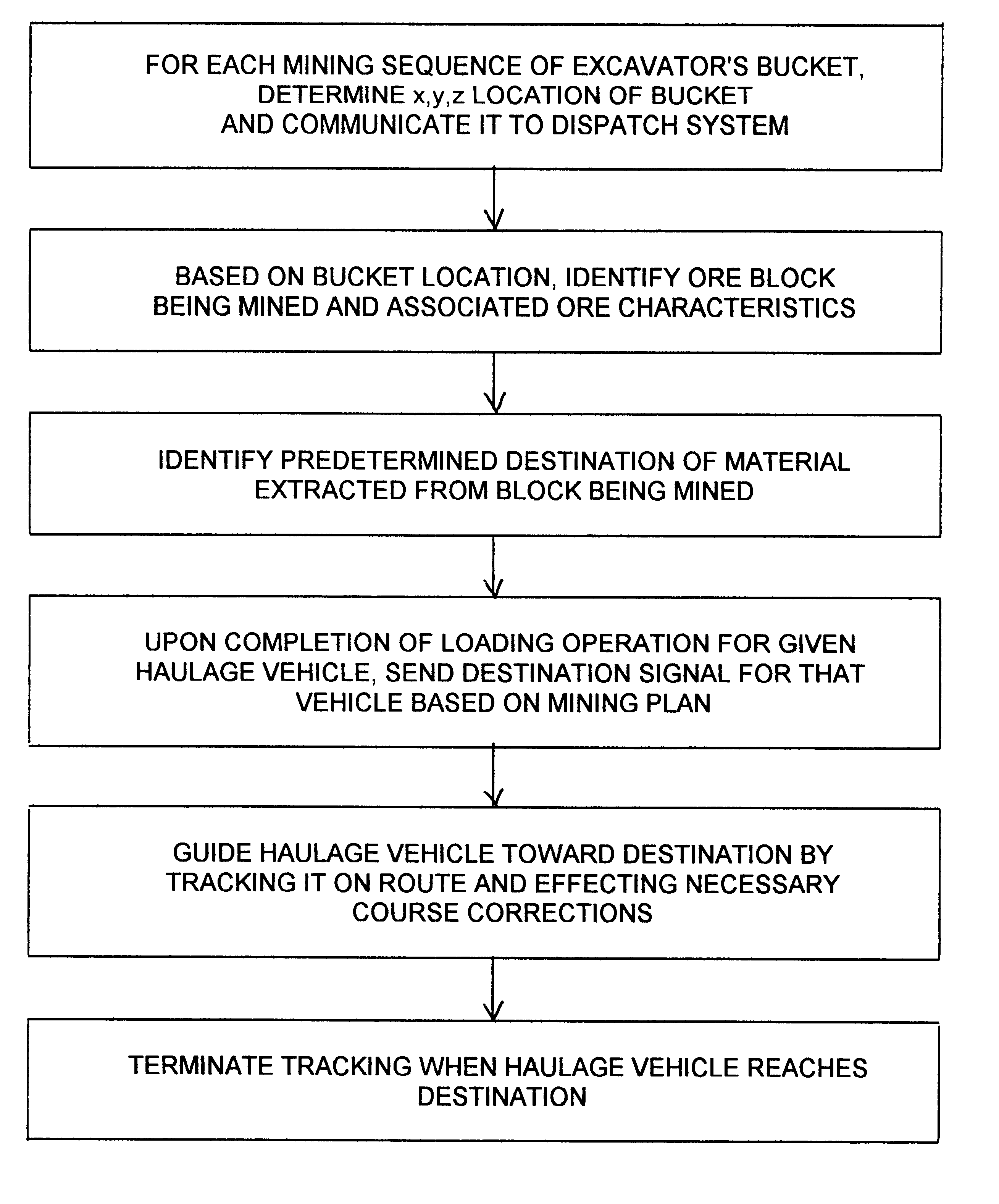

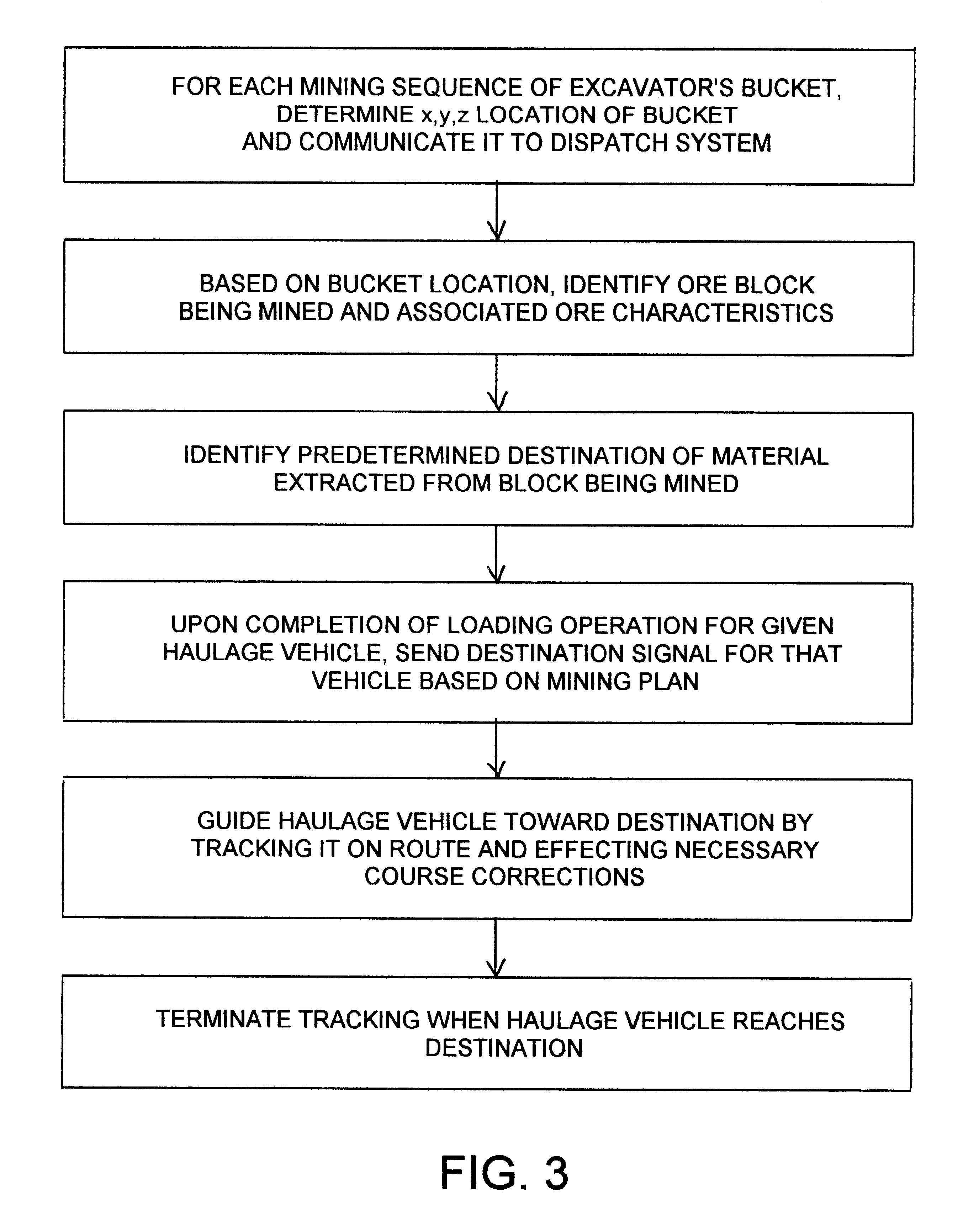

Method used

Image

Examples

Embodiment Construction

For the purposes of this disclosure, it is understood that every reference to an operator is intended to apply as well to an onboard automated control system. Surface mines utilize a variety of work machines for excavating and transporting ore, grading and stabilizing roadways and slopes in the mine pit, and providing all support functions necessary to the operation of a mine. Most work machines, such as excavators, shovels, backhoes and the like, are human-operated, mobile pieces of equipment constantly being moved around the surface of the mine. Skilled operators ensure that each mining machine is positioned in the right place and optimally oriented to perform its intended function. For example, an excavator operator will ensure that the undercarriage of the machine is sufficiently close to the minable seam and that its boom is oriented so as to permit the bucket of the machine to reach and extract a full load of ore.

In order to improve safety and efficiency, much effort is curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com