Dental model gradational-layer ceramic block and manufacture method thereof

A manufacturing method and technology of dental molds, which are applied in dentistry, dentures, and protective layers, etc., can solve problems such as poor light transmission, fading of ceramic teeth, uneven color, etc., and achieve poor light transmission and high strength. And the effect of reliability and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

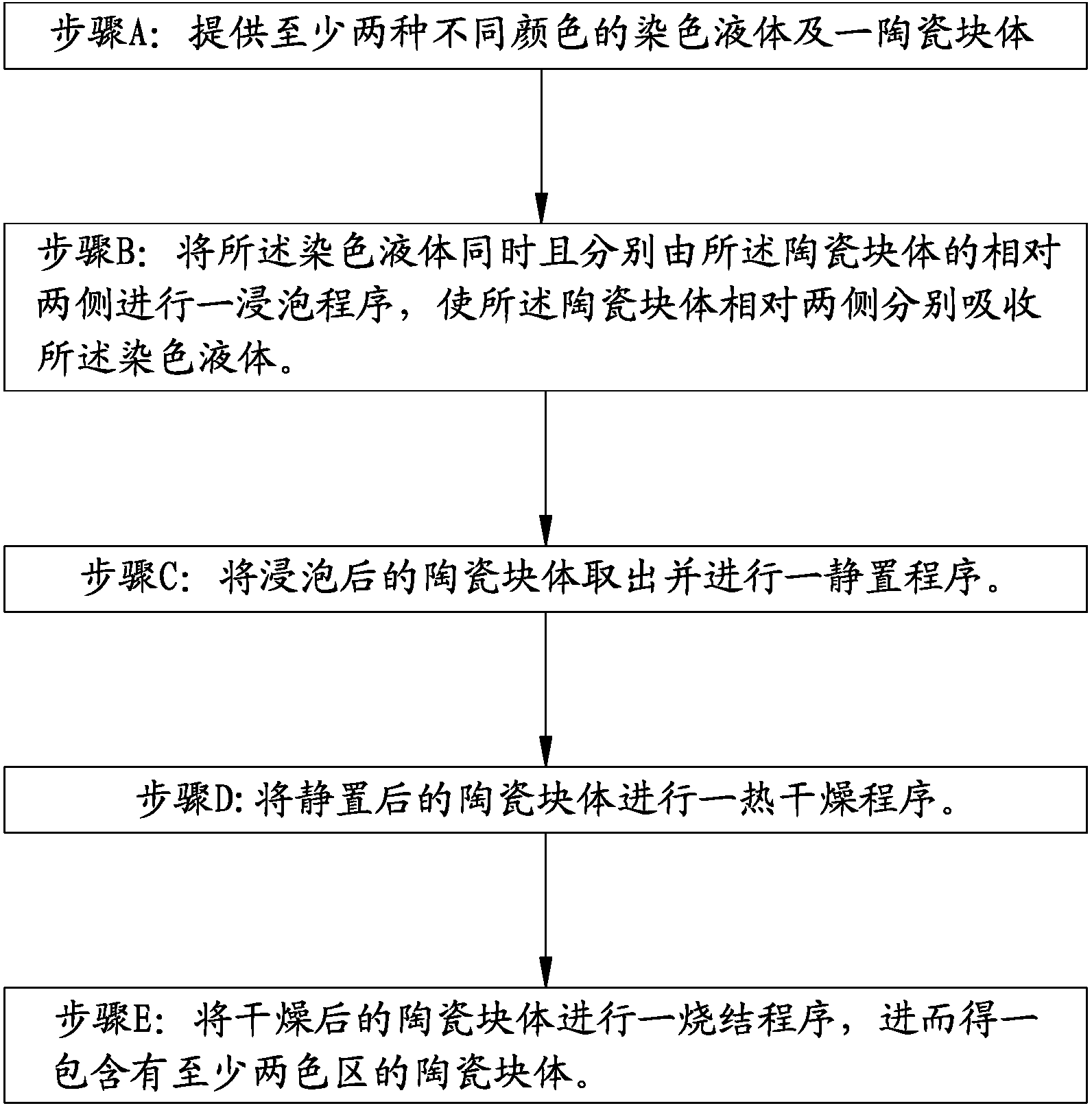

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0033] First of all, in the field of modern dentistry, all-ceramic crowns are high-strength non-metallic crowns instead of metals, decorated with dentin porcelain and incisal porcelain, and the current excellent ceramic materials include alumina and zirconia.

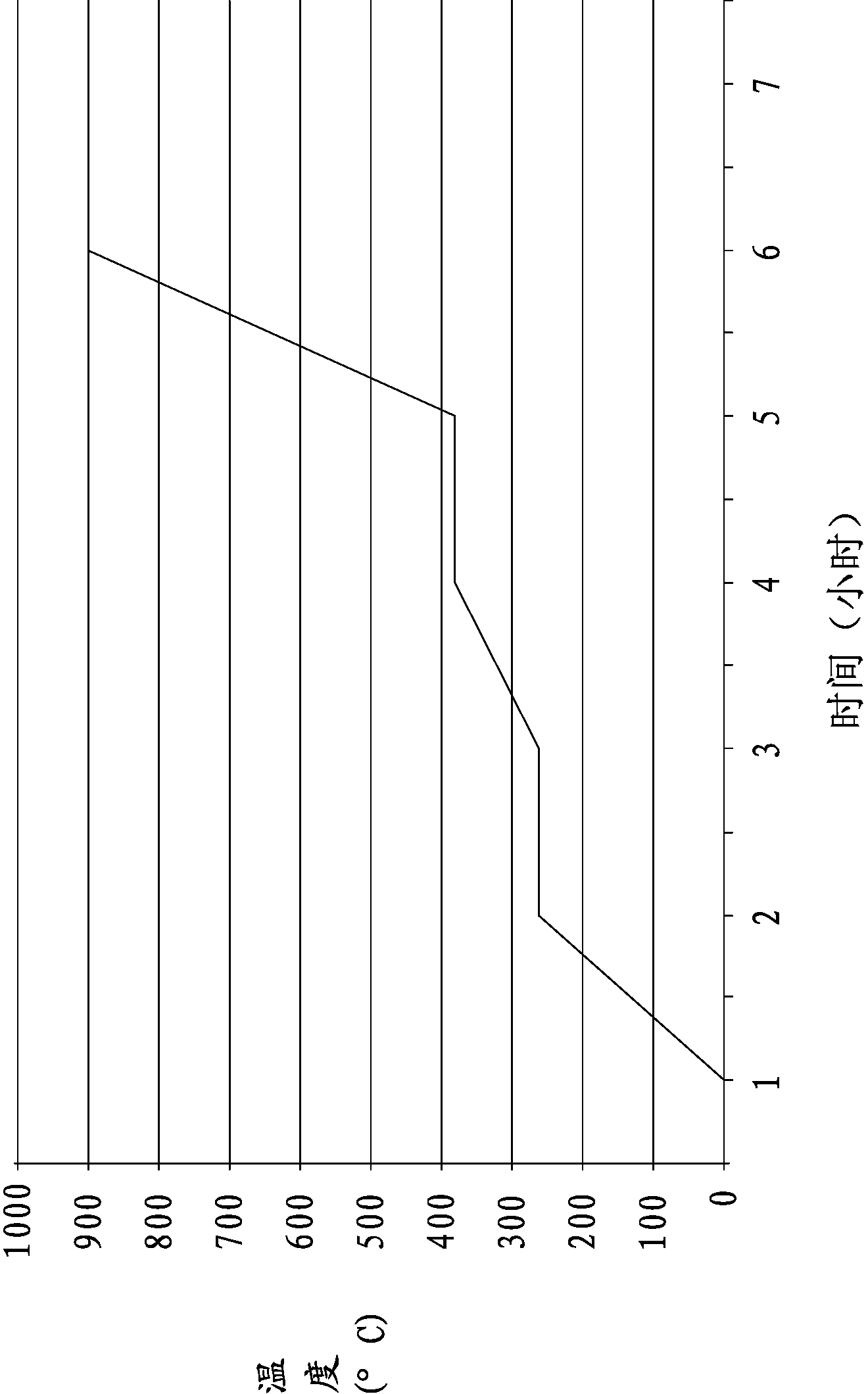

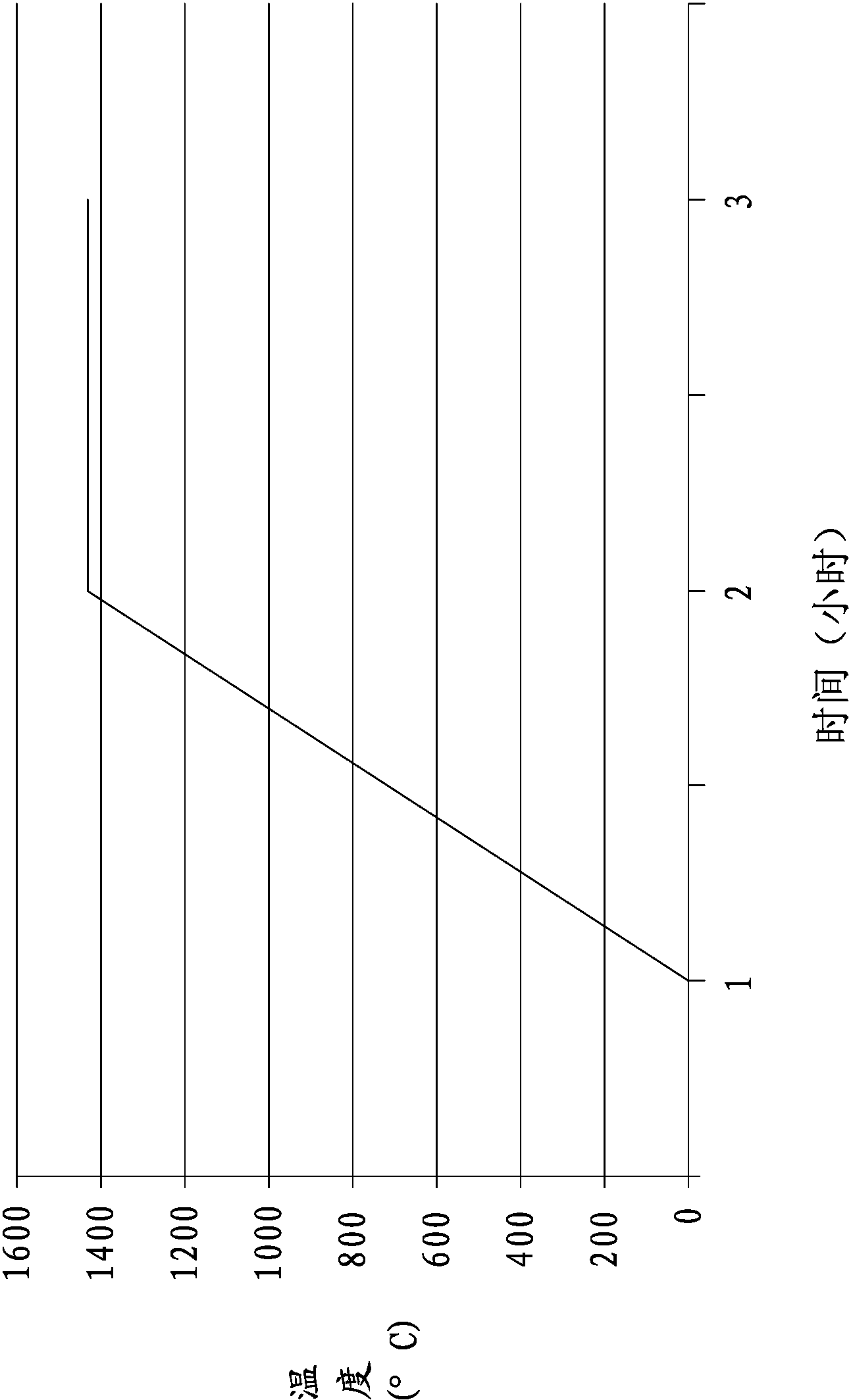

[0034] Furthermore, as shown in the table below, the process parameters of dry pressing and cold isostatic pressing are adopted for the undyed ceramic block of the present invention, that is to say, the ceramic powder must first be subjected to a forming process to form a ceramic block 1. In the embodiment of the present invention, the ceramic powder is colored or colorless, and the ceramic block 1 further includes zirconia powder, wherein zirconia has excellent properties of high toughness, chemical corrosion resistance and good biocompatibility, And it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com