Broadband wave-absorbing force bearing composite material and preparing method thereof

A composite material and broadband technology, applied in the field of radar stealth material manufacturing for weapons and equipment, can solve problems such as the influence of wave-absorbing frequency band width, unstable electrical properties of structural materials, and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

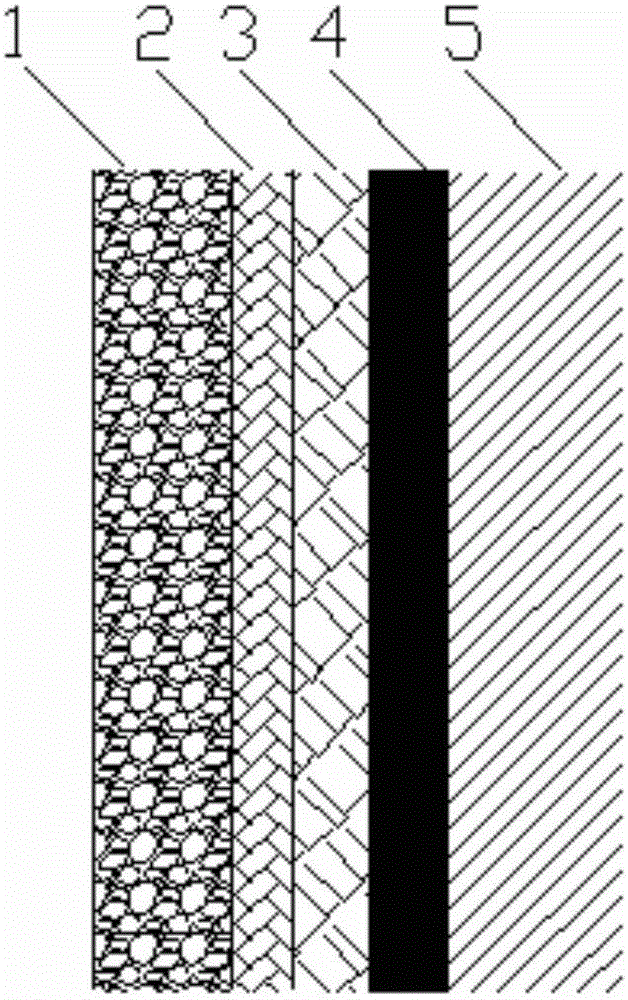

[0082] 2mm wave transparent foam + 0.4mm wave transparent layer + 0.4m electric loss absorbing layer + shielding bottom layer

[0083] Step 1: Preparation of Electric Loss Absorbing Cloth

[0084] Disperse the commercially available conductive carbon black material in the organic adhesive according to the required ratio, the mass ratio of carbon black to adhesive is 1:10, stir well, and configure the carbon black coating; use the spray gun to spray the carbon black coating evenly on the thickness of 0.2mm The surface of the wave-transparent fiber cloth, the deposition thickness of the carbon black material on the fiber cloth meets the design requirements by controlling the number of spraying times;

[0085] The above-mentioned fiber cloth is cured once, and the wave-absorbing cloth is obtained after drying.

[0086] Repeat the above steps to prepare electric loss absorbing cloths with different carbon black contents.

[0087] Step 2: Surface treatment of electric loss absorb...

Embodiment 2

[0092] 5mm wave transparent foam + 3mm wave transparent layer + 2mm electric loss absorbing layer + shielding bottom layer

[0093] Step 1: Preparation of Electric Loss Absorbing Cloth

[0094] Disperse the commercially available conductive carbon black material in the organic adhesive according to the required ratio, the mass ratio of carbon black and adhesive is 0.5:100\0.5:10\1:10, stir well, and configure it into a carbon black coating; use a spray gun to spray the carbon black The paint is evenly sprayed on the surface of the wave-transparent fiber cloth with a thickness of 0.2mm, and the deposition thickness of the carbon black material on the fiber cloth meets the design requirements by controlling the number of spraying times;

[0095] The above-mentioned fiber cloth is cured once, and the wave-absorbing cloth is obtained after drying.

[0096] Repeat the above steps to prepare electric loss absorbing cloths with different carbon black contents.

[0097] Step 2: Surf...

Embodiment 3

[0102] 15mm wave transparent foam + 5mm wave transparent layer + 5mm electric loss absorbing layer + shielding bottom layer

[0103] Step 1: Preparation of Electric Loss Absorbing Cloth

[0104] Disperse the commercially available conductive carbon black material in the organic adhesive according to the required ratio, the mass ratio of carbon black and adhesive is 0.5:100\0.5:10\1:10, stir well, and configure it into a carbon black coating; use a spray gun to spray the carbon black The paint is evenly sprayed on the surface of the wave-transparent fiber cloth with a thickness of 0.2mm, and the deposition thickness of the carbon black material on the fiber cloth meets the design requirements by controlling the number of spraying times;

[0105] The above-mentioned fiber cloth is cured once, and the wave-absorbing cloth is obtained after drying.

[0106] Repeat the above steps to prepare electric loss absorbing cloths with different carbon black contents.

[0107] Step 2: Sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com