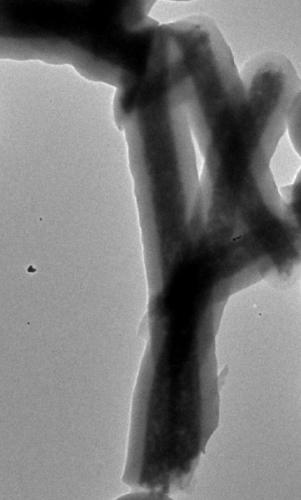

One-dimensional dual-core-shell structure nickel oxide@lanthanum nickelate@polypyrrole absorbing material and preparation method thereof

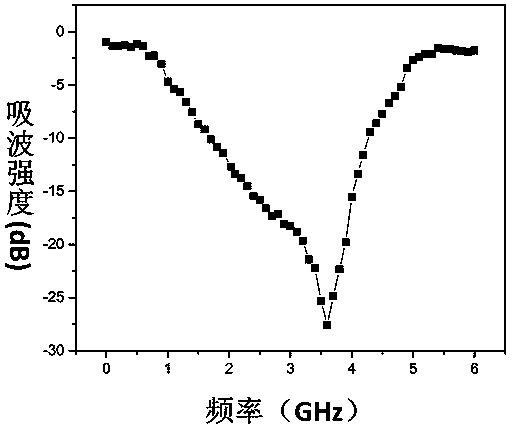

A technology of wave absorbing material and core-shell structure, applied in shielding materials, chemical characteristics of fibers, fiber processing, etc., can solve the problems of high density and narrow absorption frequency band, and achieve uniform size distribution, wide wave absorption frequency band, and excellent wave absorption. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of nickel oxide@lanthanum nickelate@polypyrrole absorbing material with one-dimensional double core-shell structure, the steps are as follows:

[0027] (1) Nickel oxide@lanthanum nickelate nanofibers were prepared by electrospinning, with Ni(NO 3 ) 2 As raw material, Ni(NO 3 ) 2 dissolved in deionized water, where Ni(NO 3 ) 2 The mass ratio to deionized water is 1:5, and the core layer spinning solution is prepared by adding polymer polyvinylpyrrolidone (PVP), and the mass ratio of polymer PVP to deionized water is 1:2; the NiCO 3 , La(NO 3 ) 3 Dissolved in 5% dilute nitric acid, where NiCO 3 and La(NO 3 ) 3 The mass ratio of the total mass of the polymer to dilute nitric acid is 1:15, while adding high polymer polyvinylpyrrolidone (PVP) to prepare the shell spinning solution, the mass ratio of high polymer PVP to dilute nitric acid is 1:5; The shell spinning solution and the core spinning solution are added to the spinning machine for s...

Embodiment 2

[0033] The preparation method of nickel oxide@lanthanum nickelate@polypyrrole absorbing material with one-dimensional double core-shell structure, the steps are as follows:

[0034](1) Nickel oxide@lanthanum nickelate nanofibers were prepared by electrospinning, with Ni(NO 3 ) 2 As raw material, Ni(NO 3 ) 2 dissolved in deionized water, where Ni(NO 3 ) 2 The mass ratio to deionized water is 1: 10, and the core layer spinning solution is prepared by adding polymer polyvinylpyrrolidone (PVP), and the mass ratio of polymer PVP to deionized water is 1: 4; the NiCO 3 , La(NO 3 ) 3 Dissolved in 8 % dilute nitric acid, where NiCO 3 , La(NO 3 ) 3 The mass ratio of high polymer PVP to dilute nitric acid is 1:18, and at the same time, high polymer polyvinylpyrrolidone (PVP) is added to prepare the shell spinning solution. The mass ratio of high polymer PVP to dilute nitric acid is 1:8; the shell spinning The silk solution and the core layer spinning solution were added to the ...

Embodiment 3

[0039] The preparation method of nickel oxide@lanthanum nickelate@polypyrrole absorbing material with one-dimensional double core-shell structure, the steps are as follows:

[0040] (1) Nickel oxide@lanthanum nickelate nanofibers were prepared by electrospinning, with Ni(NO 3 ) 2 As raw material, Ni(NO 3 ) 2 dissolved in deionized water, where Ni(NO 3 ) 2 The mass ratio to deionized water is 1:7, and the core layer spinning solution is prepared by adding high polymer polyvinylpyrrolidone (PVP), and the mass ratio of high polymer PVP to deionized water is 1:3; the NiCO 3 , La(NO 3 ) 3 Dissolved in 7% dilute nitric acid, where NiCO 3 , La(NO 3 ) 3 The mass ratio of high polymer PVP to dilute nitric acid is 1:17, and at the same time, high polymer polyvinylpyrrolidone (PVP) is added to prepare the shell spinning solution. The mass ratio of high polymer PVP to dilute nitric acid is 1:6; the shell spinning The silk liquid and the core layer spinning liquid were added to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com