Microwave sintering method for SiC ceramic roller

A ceramic roller and microwave sintering technology, which is applied in the field of SiC ceramics, can solve the problems of over-burning at the flame port, long sintering time of silicon carbide ceramic rollers under normal pressure, and uneven sintering of materials, so as to achieve short sintering time and solve the problems The effect of long sintering time at normal pressure, improving uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The microwave sintering method of the SiC ceramic roller rod of the present embodiment comprises the following steps:

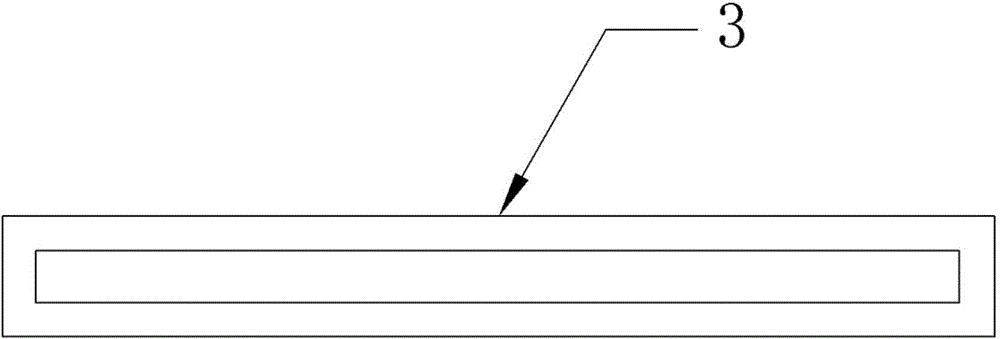

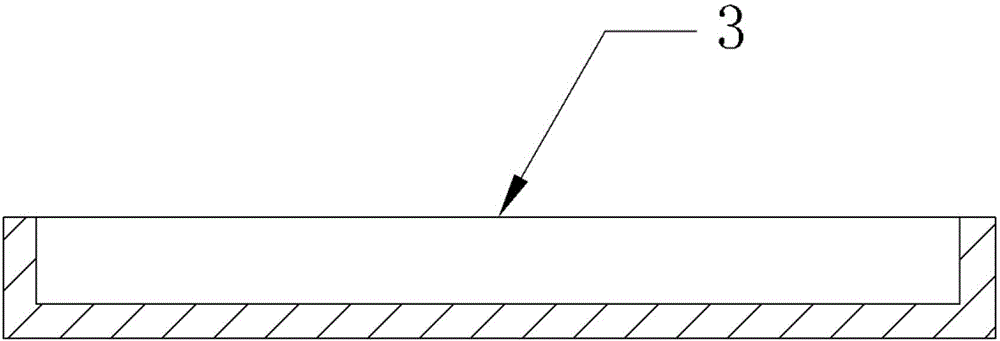

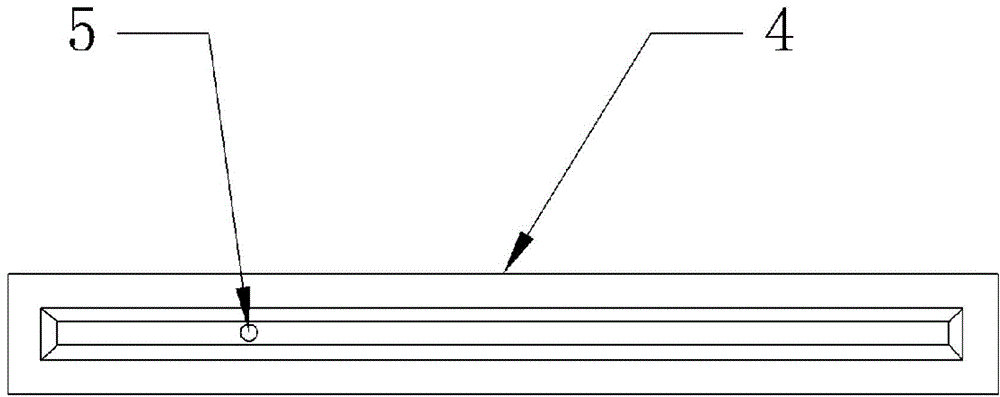

[0033] 1) Put the SiC ceramic roller green body into the heat preservation device, and then place it together with the heat preservation device in the microwave resonant cavity; the function of the heat preservation device is to ensure the uniform temperature distribution of the roller during the sintering process; The billet is provided by Foshan Ceramics Research Institute with a length of 1220mm, an outer diameter of 62mm, and an inner diameter of 56mm. There is an axially hollow SiC ceramic roller rod, which is made of alumina, silicon carbide, and clay. It is prepared by compression molding and 260MPa cold isostatic pressing; the weight ratio of alumina, silicon carbide and clay is 29:55:13.

[0034] 2) Turn on the microwave source, adjust the microwave input frequency, raise the temperature at a rate of 6°C / min in the low temperature stage to the...

Embodiment 2

[0038] The microwave sintering method of the SiC ceramic roller rod of the present embodiment comprises the following steps:

[0039] 1) Put the SiC ceramic roller green body into the heat preservation device, and then place it together with the heat preservation device in the microwave resonant cavity; the function of the heat preservation device is to ensure the uniform temperature distribution of the roller during the sintering process; The billet is provided by Foshan Ceramic Research Institute with a length of 1000mm, an outer diameter of 50mm, and an inner diameter of 45mm. There is an axially hollow SiC ceramic roller rod, which is made of alumina, silicon carbide, and clay. It is prepared by pressing and 260MPa cold isostatic pressing; the weight ratio of alumina, silicon carbide and clay is 30:35:10.

[0040] 2) Turn on the microwave source, adjust the microwave input frequency, raise the temperature at a rate of 15°C / min in the low temperature stage to the end of moi...

Embodiment 3

[0042] The microwave sintering method of the SiC ceramic roller rod of the present embodiment comprises the following steps:

[0043] 1) Put the SiC ceramic roller green body into the heat preservation device, and then place it together with the heat preservation device in the microwave resonant cavity; the function of the heat preservation device is to ensure the uniform temperature distribution of the roller during the sintering process; The billet is provided by the Foshan Ceramic Research Institute with a length of 1160mm, an outer diameter of 55mm, and an inner diameter of 50mm. There is an axially hollow SiC ceramic roller rod, which is made of alumina, silicon carbide, and clay. It is prepared by pressing; the weight ratio of alumina, silicon carbide and clay is 33:45:15.

[0044] 2) Turn on the microwave source, adjust the microwave input frequency, raise the temperature at a rate of 10°C / min in the low temperature stage until the end of dehumidification and smoke exha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com