A kind of resin wave-absorbing coating and preparation method thereof

A technology of wave-absorbing paint and resin, applied in epoxy resin paint, radiation-absorbing paint, coating, etc., can solve the problems of poor wave-absorbing performance of wave-absorbing paint, limited application range, narrow frequency band, etc. The effect of uneven and easy to agglomerate, low cost and wide absorption frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The present invention also provides a preparation method of resin wave-absorbing coating, comprising the following steps:

[0075] A) after mixing graphene oxide and ferric oxide for the first time, obtain the composite material of graphene and ferric oxide;

[0076]B) After mixing the composite material of graphene and ferroferric oxide obtained in the above steps, resin, dispersant, anti-sedimentation agent and solvent, the resin wave-absorbing coating is obtained.

[0077] In the present invention, the selection and composition of raw materials required in the above-mentioned preparation process, as well as the corresponding optimization principles, can correspond to the selection and composition of the corresponding raw materials in the aforementioned resin wave-absorbing coating, as well as the corresponding optimization principles, and will not be repeated here Let me repeat them one by one.

[0078] In the present invention, firstly, the composite material of gr...

Embodiment 1

[0127] Graphene / Ferric Oxide Composite

[0128]1. Prepare a graphene oxide aqueous solution, and obtain a 0.1mg / ml graphene oxide dispersion solution after ultrasonic dispersion treatment; then prepare a ferrous sulfate aqueous solution with a concentration of 0.2mol / L;

[0129] 2. Heat the graphene oxide dispersion solution in step 1 to 50°C and continue ultrasonication for 30 minutes, slowly add the ferrous sulfate aqueous solution to the graphene oxide dispersion solution at a rate of 5ml / min to obtain a precursor mixed solution;

[0130] 3. Heat the precursor mixed solution in step 2 to 90°C and continue ultrasonication for 30 minutes, add 30ml of 0.1mol / L sodium hydroxide aqueous solution, and adjust the pH of the system to 10;

[0131] 4. After the reaction system was kept at 90°C and the ultrasonic reaction was continued for 120 minutes, the reaction product was obtained, and after magnetic separation several times, it was vacuum-dried at 60°C for 8 hours, and the black...

Embodiment 2

[0138] In terms of weight percentage, first add 20.7% xylene and 34.5% graphene / iron tetroxide composite material and mix and ultrasonically stir for 30 minutes, then add 0.5% polyvinylpyrrolidone and mix and stir for 10 minutes at a speed of 300r / min; 10.3% xylene and 27.6% epoxy resin DY128 medium-speed ultrasonic dispersion, then cast 5% carbon black, 0.5% MONORAL 3300 for 1500r / min high-speed dispersion, add 0.4% phthalate, then 900r / min low-speed dispersion, and then filter, paint and filter, blend and defoam and pack to get the finished product.

[0139] The application performance test of the wave-absorbing coating prepared in Example 2 of the present invention was carried out.

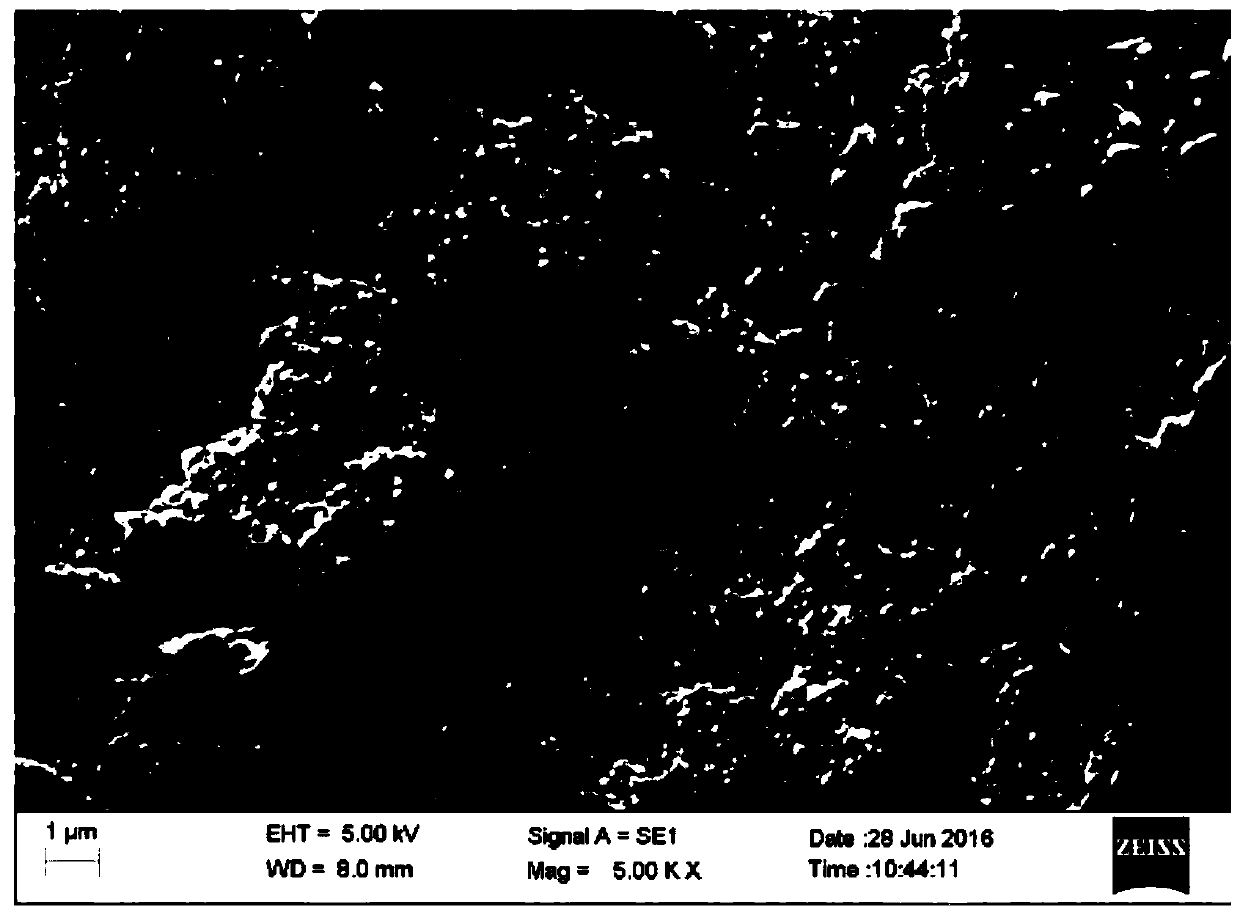

[0140] see figure 2 , figure 2 The section result diagram of the coating when the wave-absorbing coating prepared for the present invention is used. Depend on figure 2 It can be seen that the graphene / ferroferric oxide is densely arranged at the cross-section, showing a sheet state, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com