Permeability detecting device and saturated permeability detecting method fiber spread layer surface and thickness direction

A fiber lay-up and testing device technology, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. problem, to achieve the effect of high test efficiency, small measurement error and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

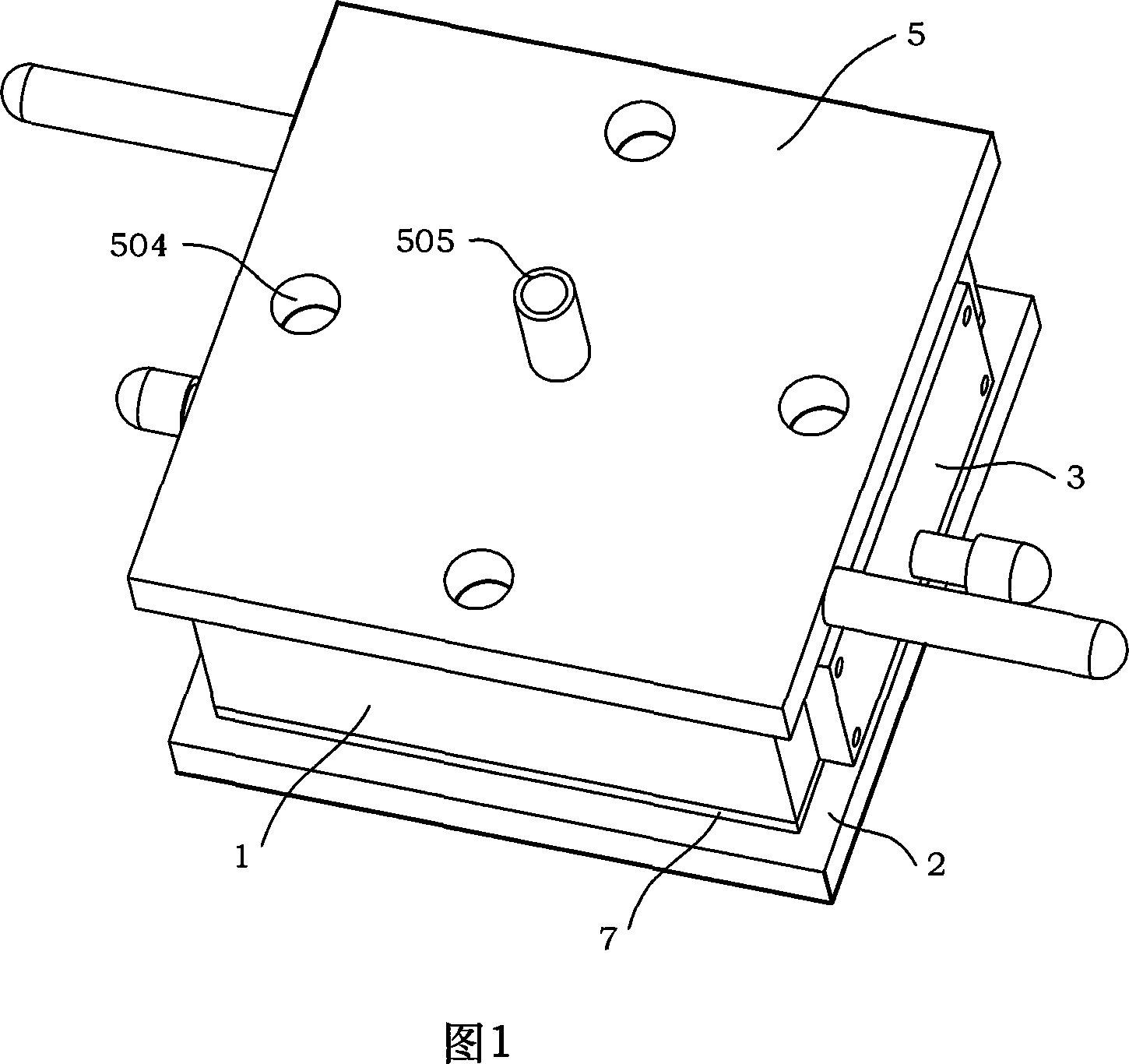

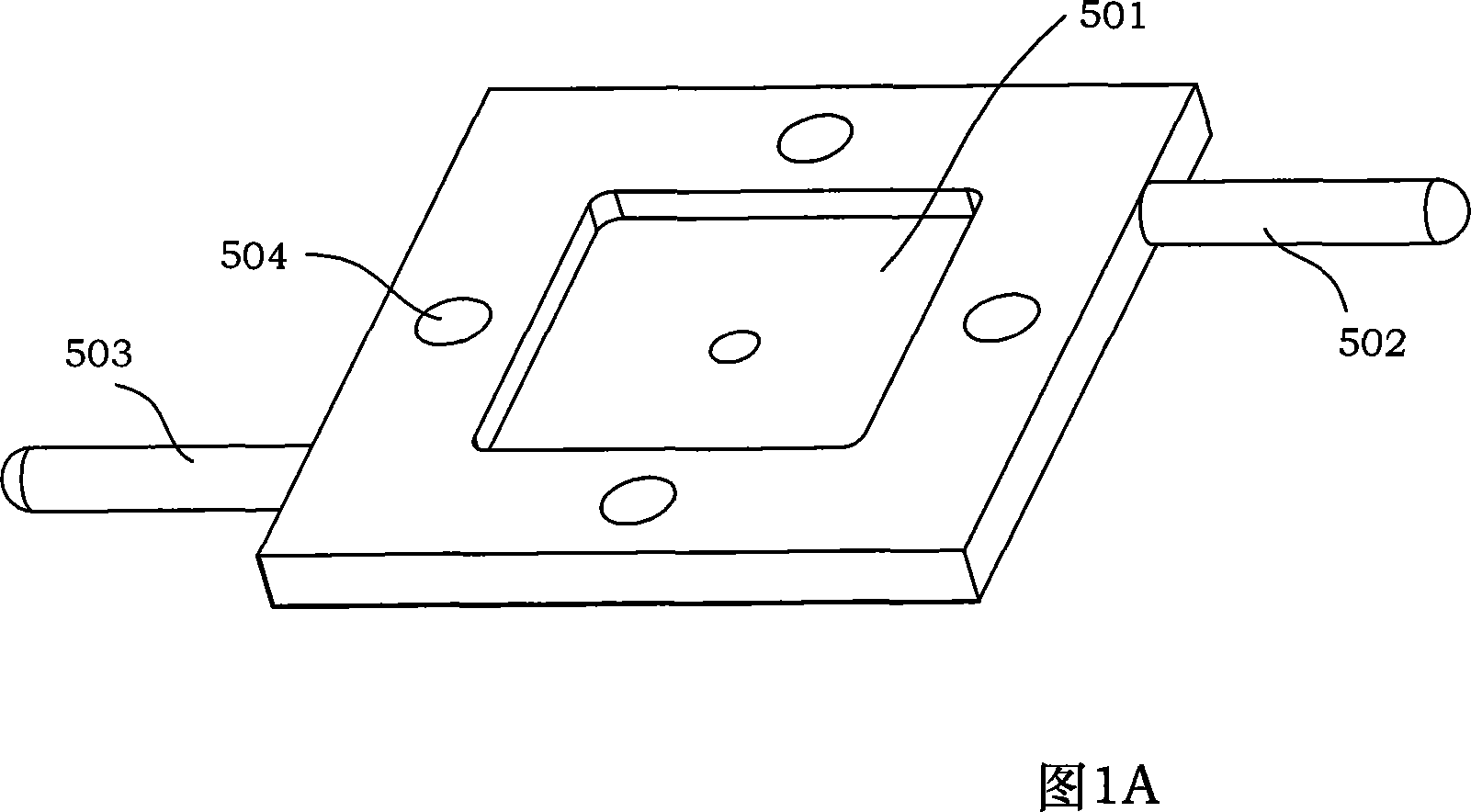

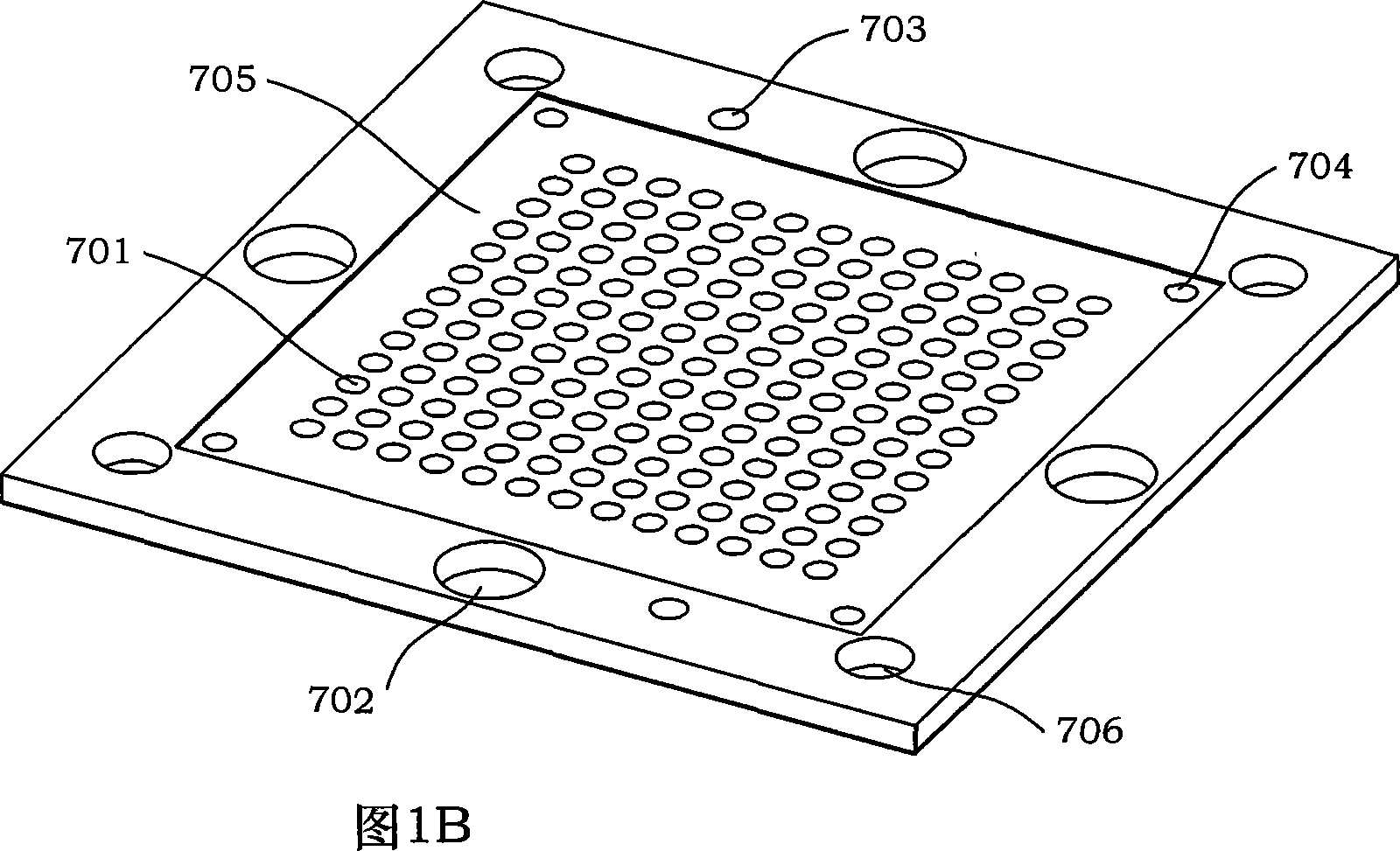

Method used

Image

Examples

Embodiment 1

[0078] S-2 high-strength glass fiber / epoxy E51 resin unidirectional prepreg is used as the test object. Cut the prepreg into 10×10cm 2 Finally, 40 layers are laid, and the laying method is one-way laying; after dissolving the epoxy E51 resin with acetone, soak the fiber laying layer with soybean oil, and then use a small press as a pressurizing device, and use soybean oil as a test liquid. Measure the fiber volume fraction in the range of 47% to 71% and the saturated permeability in the thickness direction of the fiber layer, the pressure P is adjusted in the range of 0.01 to 0.08MPa, the experimental temperature is 20°C, and the viscosity of soybean oil at this temperature is 0.06Pa s, the test results are shown in Table 1 and Table 2.

[0079] Fiber volume fraction (%)

[0080] Fiber volume fraction (%)

Embodiment 2

[0082] T700 carbon fiber plain weave fabric is used as the test object. Cut the fabric to 10×10cm 2 After laying 20 layers, the laying method is orthogonal laying; use a small press as the pressurizing equipment, and use corn steep liquor as the test liquid to measure the saturated permeability in the fiber laying layer and in the thickness direction when the fiber volume fraction is 60%. , the pressure P is adjusted within the range of 0.03-0.05MPa, the experimental temperature is 15°C, the viscosity of corn steep liquor at this temperature is 0.04Pa·s, and the saturated permeability in the fiber layup layer and in the thickness direction obtained from the test is 6.2×10 -12 m 2 and 7.8×10 -13 m 2 .

Embodiment 3

[0084] T300 carbon fiber twill fabric is used as the test object. Cut the fabric to 10×10cm 2 After laying 35 layers, the layering method is quasi-isotropic layering; a small press is used as a pressurized device, soybean oil is used as a test liquid, and the fiber layer and thickness direction saturation are measured when the fiber volume fraction is 55%. Permeability, the pressure P is adjusted in the range of 0.07-0.09MPa, the experimental temperature is 25°C, the viscosity of soybean oil at this temperature is 0.03Pa·s, and the saturated permeability in the fiber layer and thickness direction obtained from the test are 13.2× 10 -12 m 2 and 10.1×10 -14 m 2 .

[0085] V f

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com