High-permeability sand-burning-preventing paint for casting and preparation method thereof

A high-permeability, anti-sticking sand technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of inability to effectively fill the gap between sand grains, insufficient high-temperature strength of the coating, and easy sedimentation and agglomeration of the coating. problems, to achieve the effect of improving stability and brushability, ensuring hanging and coating strength, and preventing sticky sand defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 50 kg of zircon powder, 50 kg of chromite powder, 1.5 kg of phenolic resin, 0.1 kg of oxidized rosin, 0.4 kg of ethyl silicate, 0.03 kg of alkylphenol polyoxyethylene ether, 95 kg of ethanol, polyvinyl alcohol 0.2 kg of butyraldehyde, 3 kg of lithium-based bentonite, 0.05 kg of n-butanol; the particle size of zircon powder and chromite powder is 325-500 mesh, which can be purchased from the market with a particle size of 325-500 mesh, or through grinding 325-500 mesh.

[0036] First, make the lithium-based bentonite fully swell with an appropriate amount of water, and use part of ethanol (alcohol) to make a saturated solution of phenolic resin, oxidized rosin, and polyvinyl butyral respectively, and wait for use; when using (in order to achieve the best effect) , the rest of the ingredients are best prepared at the time of use), part of ethanol, phenolic resin solution, oxidized rosin solution, polyvinyl butyral solution, ethyl silicate, swollen lithium-based bent...

Embodiment 2-20

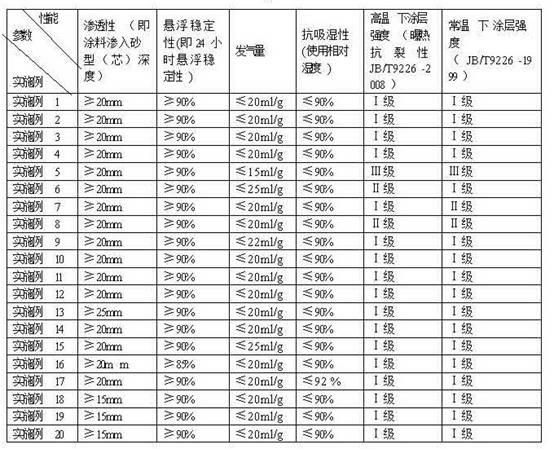

[0038] Embodiment 2-20 except that raw material composition and proportion are different from embodiment 1, its manufacturing process is the same as embodiment 1, and the raw material composition that all embodiment 1-20 adopts is shown in the following table 1.

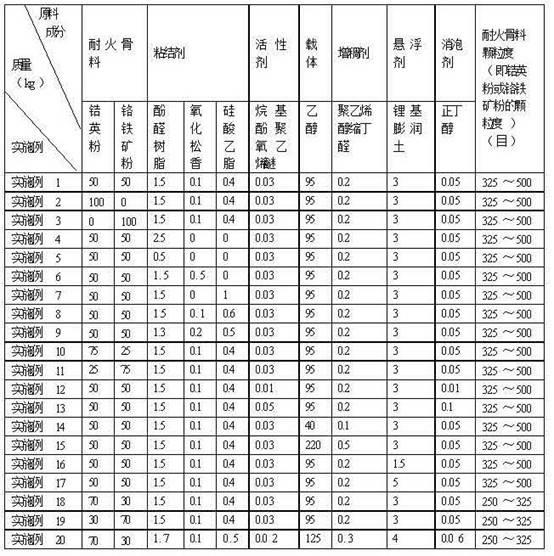

[0039] The test characteristics of the high-permeability anti-sand sticking coatings for foundry obtained in Examples 1-20 are shown in Table 2 below.

[0040] Table 1

[0041]

[0042] Table 2

[0043]

[0044] During use, the thickness of 0-0.5mm before the molding sand coating, the particle size of the refractory aggregate used in the coating obtained by the present invention is 325-500 mesh zircon powder and chromite powder, and the refractory aggregate is more likely to penetrate into the pores of the sand mold, improving the Penetration properties of coatings, filling the gaps between sand grains, and preventing castings from sticking to sand; after the molding sand is coated with a thickness of 0.5-2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com