Fiber-toughened cement-emulsified asphalt-based mixture and preparation method thereof

A cement emulsified asphalt and fiber toughening technology, which is applied in the field of fiber toughened cement emulsified asphalt base mixture and its preparation, can solve the problem of increasing the brittle cracking of cement emulsified asphalt concrete, not fully exerting the composite effect of materials, and not paying attention to the bridging and strengthening effect. and other problems, to achieve the effect of solving insufficient adhesion, good construction performance and moderate price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

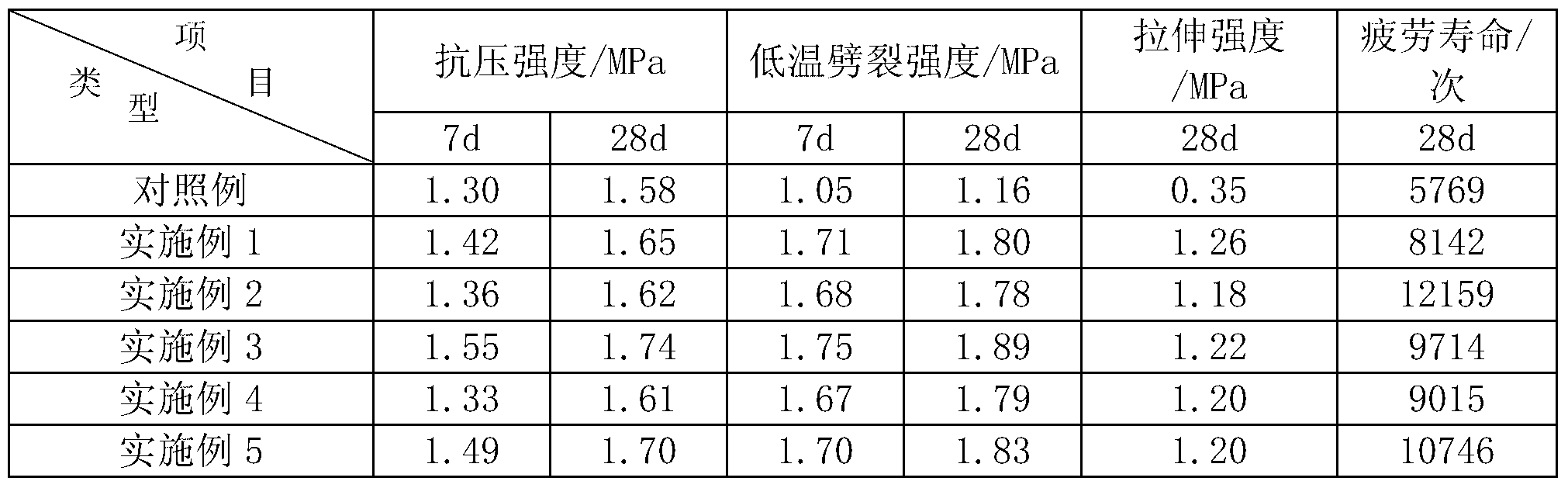

Examples

Embodiment 1

[0029] Aggregate gradation type: AC-13

[0030] Brucite mineral fiber: cement: emulsified asphalt: bisphenol A type epoxy resin: diethylenetriamine: aggregate = 0.2 parts: 2.8 parts: 7.0 parts: 1.3 parts: 0.4 parts: 88.3 parts.

[0031] First, weigh brucite mineral fiber, cement, emulsified asphalt, bisphenol A epoxy resin, diethylenetriamine, and aggregate according to the proportion of ingredients, and set aside; then add brucite mineral fiber to the aggregate at room temperature After medium-dry mixing, add appropriate amount of water and mix again, then add emulsified asphalt, bisphenol A epoxy resin and diethylenetriamine in turn for mixing, and finally add cement and mix evenly to obtain a fiber-toughened cement emulsified asphalt-based mixture material.

Embodiment 2

[0033] Aggregate gradation type: AC-13

[0034] Brucite mineral fiber: cement: emulsified asphalt: bisphenol A type epoxy resin: diethylenetriamine: aggregate = 0.4 parts: 2.0 parts: 8.0 parts: 1.5 parts: 0.5 parts: 87.6 parts.

[0035] According to the operation steps of Example 1, the fiber-toughened cement emulsified asphalt-based mixture can be prepared.

Embodiment 3

[0037] Aggregate Grading Type: AC-13

[0038] Brucite mineral fiber: cement: emulsified asphalt: bisphenol A type epoxy resin: diethylenetriamine: aggregate = 0.5 parts: 2.5 parts: 6.0 parts: 1.9 parts: 0.6 parts: 88.5 parts.

[0039] According to the operation steps of Example 1, the fiber-toughened cement emulsified asphalt-based mixture can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com