Anti-backflow leak-stopping agent, preparation method and applications thereof

A plugging agent and anti-return technology, which is applied in the field of plugging agents, can solve the problems of bridging material regurgitation, plugging operation failure, poor anti-flowback ability of the plugging layer, etc., and achieve a relaxed use environment, moderate economic cost, The effect of improving the anti-reverse discharge ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

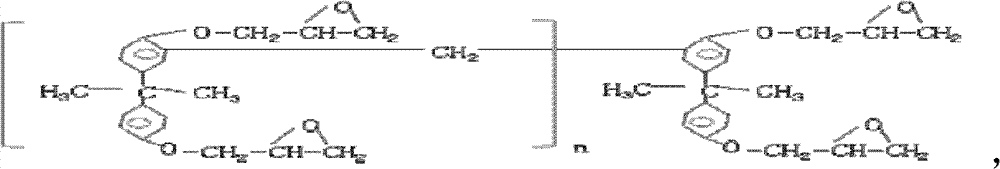

[0038] Add 100g bisphenol A type epoxy resin in 1L high temperature and high pressure reactor, as

[0039]

[0040] Add 500ml of benzene, add 0.2g of benzoyl peroxide, heat up to 150°C, dissolve under stirring at a speed of 300r / min, add 20g of maleic anhydride through a feeder, and react at a constant temperature for 120min. The pressure in the kettle must not exceed 0.3MPa. After the pressure in the kettle dropped to zero, the material was discharged at room temperature, and distilled under reduced pressure at 90°C to obtain a brownish-yellow viscous liquid, which was the modified self-emulsifying epoxy resin. Then take 10-30 mesh quartz sand and heat it to 166°C; in mechanical stirring, add modified self-emulsifying epoxy resin to the hot quartz sand, wherein the quartz sand and modified self-emulsifying epoxy resin The weight ratio is 94:6, and the stirring is continued for 100-120 minutes; the temperature of the mixture of quartz sand and modified self-emulsifying epox...

Embodiment 2

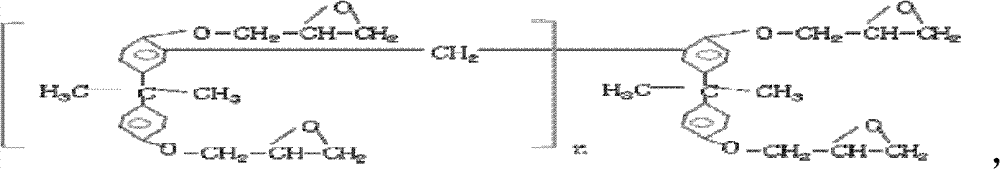

[0042] Add 100g bisphenol A type epoxy resin in 1L high temperature and high pressure reactor, as

[0043]

[0044]Add 500ml of benzene, add 0.2g of benzoyl peroxide, heat up to 150°C, dissolve under stirring at a speed of 300r / min, add 20g of maleic anhydride through a feeder, and react at a constant temperature for 120min. The pressure in the kettle must not exceed 0.3MPa. After the pressure in the kettle dropped to zero, the material was discharged at room temperature, and distilled under reduced pressure at 90°C to obtain a brownish-yellow viscous liquid, which was the modified self-emulsifying epoxy resin. Then take 10-30 mesh quartz sand and heat it to 166°C; in mechanical stirring, add modified self-emulsifying epoxy resin to the hot quartz sand, wherein the quartz sand and modified self-emulsifying epoxy resin The weight ratio is 84:16, and the stirring is continued for 100-120 minutes; the temperature of the mixture of quartz sand and modified self-emulsifying epox...

Embodiment 3

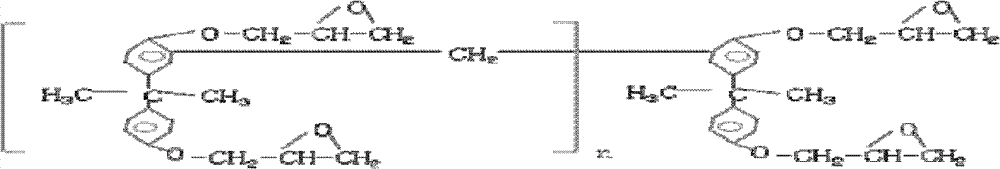

[0046] Add 100g bisphenol A type epoxy resin in 1L high temperature and high pressure reactor, as

[0047]

[0048] Add 500ml of benzene, add 0.2g of benzoyl peroxide, heat up to 150°C, dissolve under stirring at a speed of 300r / min, add 20g of maleic anhydride through a feeder, and react at a constant temperature for 120min. The pressure in the kettle must not exceed 0.3MPa. After the pressure in the kettle dropped to zero, the material was discharged at room temperature, and distilled under reduced pressure at 90°C to obtain a brownish-yellow viscous liquid, which was the modified self-emulsifying epoxy resin. Then take 10-30 mesh quartz sand and heat it to 166°C; in mechanical stirring, add modified self-emulsifying epoxy resin to the hot quartz sand, wherein the quartz sand and modified self-emulsifying epoxy resin The weight ratio is 72:28, and the stirring is continued for 100-120 minutes; the temperature of the mixture of quartz sand and modified self-emulsifying epo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com