Method for making cable-material flame-retardant of natural brucite magnesium hydrate

A technology of magnesium hydroxide and natural water, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of increasing costs and achieve the effect of low modification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

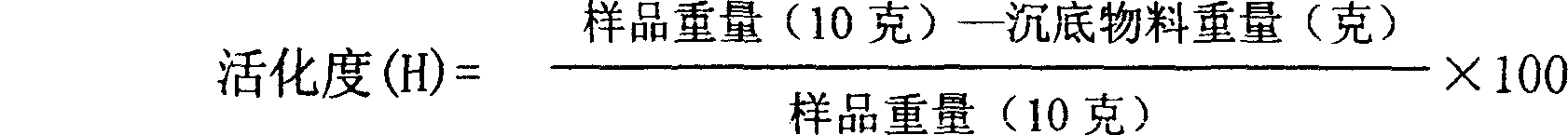

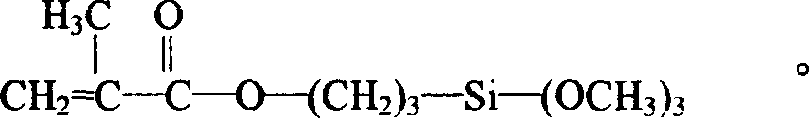

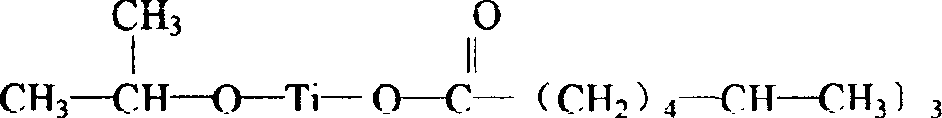

[0019] The preparation method of natural brucite magnesium hydroxide flame retardant for cable material of the present invention is made up of following steps:

[0020] (A) Selecting raw materials: choose flake natural brucite produced in Dandong as raw material. The natural brucite produced in Dandong has outstanding mineral properties, and all indicators fully meet the raw material requirements for making flame retardants;

[0021] (B), raw material pretreatment: the natural brucite raw material is carried out manual screening or machine screening to obtain the natural brucite ore with high content and good whiteness;

[0022] (C), crushing treatment: adopt airflow mill to carry out airflow collision crushing, obtain natural brucite magnesium hydroxide particles, adopt diffraction method to detect through laser particle size analyzer, its particle size is d 97 = 2μm;

[0023] (D), magnetization treatment: the brucite magnesium hydroxide particles obtained above are removed ...

Embodiment 2

[0029] The preparation method of natural brucite magnesium hydroxide flame retardant for cable material of the present invention is made up of following steps:

[0030] (A), select raw material: with embodiment 1;

[0031] (B), raw material pretreatment: with embodiment 1;

[0032] (C), crushing treatment: adopt airflow mill to carry out airflow collision crushing, obtain natural brucite magnesium hydroxide particles, adopt diffraction method to detect through laser particle size analyzer, its particle size is d 97 = 10 μm;

[0033] (D), magnetization treatment: with embodiment 1;

[0034] (E), the choice of modifier and magnetization treatment: the modifier chooses aminosilane coupling agent, with KH-550 (γ-aminopropyltriethoxysilane, its structural formula is: H 2 N(CH 2 ) 3 -Si-(OC 2 h 5 ) 3 For example, set KH-550 as coupling agent II; magnetize coupling agent II;

[0035] (F), modification treatment: put the above-mentioned natural brucite magnesium hydroxide par...

Embodiment 3

[0038] The preparation method of natural brucite magnesium hydroxide flame retardant for cable material of the present invention is made up of following steps:

[0039] (A), select raw material: with embodiment 1;

[0040] (B), raw material pretreatment: with embodiment 1;

[0041] (C), crushing treatment: adopt airflow mill to carry out airflow collision crushing, obtain natural brucite magnesium hydroxide particles, adopt diffraction method to detect through laser particle size analyzer, its particle size is d 97 = 5 μm;

[0042] (D), magnetization treatment: with embodiment 1;

[0043] (E), selection of modifying agent and magnetization treatment: the modifying agent selects olefin-based silane coupling agent, taking A-171 (vinyltrimethylsilane) as an example, A-171 is defined as coupling agent I; Carry out magnetization treatment to coupling agent I;

[0044] (F), modification treatment: put the above-mentioned natural brucite magnesium hydroxide particles into the mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com