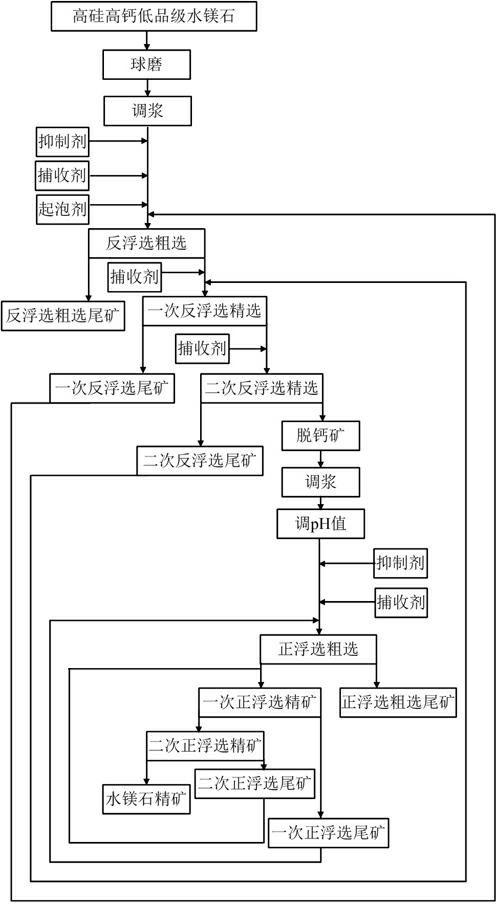

Step-by-step flotation method for high-silicon high-calcium low-grade brucite

A step-by-step flotation, low-grade technology, used in flotation, solid separation, etc., to achieve the effect of improving the flotation environment, stable operation and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The main components of high silicon, high calcium and low grade brucite raw materials contain MgO53.08%, SiO 2 12.29%, CaO 4.75%, Al 2 o 3 0.07%, the balance is impurities;

[0027] Ball mill high-silicon, high-calcium and low-grade brucite to a fineness of ≤0.074mm, accounting for 70% of the total weight of all materials, and then add water to make raw ore pulp with a weight concentration of 20%;

[0028] Put the raw ore slurry into the flotation equipment, under the condition of stirring speed 1600rpm, first add inhibitor water glass and stir for 3min, the amount of water glass added is 800g / t, then add collector dodecylamine and stir for 3min, dodecylamine The addition amount is 100g / t raw ore pulp, then add foaming agent terpineol oil and stir for 60s, the addition amount of terpineol oil is 10g / t raw ore pulp, and then carry out 4min reverse flotation roughing to sort out calcium-containing tailings , to obtain rough concentrate;

[0029] The coarse concentra...

Embodiment 2

[0036]The main components of high-silicon, high-calcium and low-grade brucite raw materials contain MgO58.08%, SiO 2 5.29%, CaO4.75%, Al 2 o 3 0.07%, the balance is impurities;

[0037] Ball mill high-silicon, high-calcium and low-grade brucite to a fineness of ≤0.074mm, accounting for 80% of the total weight of all materials, and then add water to make raw ore pulp with a weight concentration of 30%;

[0038] Put the raw ore slurry into the flotation equipment, under the condition of stirring speed 1700rpm, first add inhibitor water glass and stir for 4min, the addition of water glass is 900g / t raw ore pulp, then add collector dodecylamine and stir for 4min, ten The amount of diamine added is 150g / t raw ore pulp, then terpineol oil is added and stirred for 80s, the amount of terpineol oil added is 15g / t raw ore pulp, and then 5min reverse flotation roughing is carried out to separate the calcium-containing tailings , to obtain rough concentrate;

[0039] The coarse concen...

Embodiment 3

[0046] The main components of high silicon, high calcium and low grade brucite raw materials contain MgO59.08%, SiO 2 3.29%, CaO3.75%, Al 2 o 3 0.07%, the balance is impurities;

[0047] Ball mill high-silicon, high-calcium and low-grade brucite to a fineness of ≤0.074mm, accounting for 95% of the total weight of all materials, and then add water to make raw ore pulp with a weight concentration of 40%;

[0048] Put the raw ore pulp into the flotation equipment, under the condition of stirring speed 1800rpm, first add inhibitor water glass and stir for 3min, the water glass addition is 1500g / t raw ore pulp, then add collector dodecylamine and stir for 3min, twelve The amount of amine added is 200g / t of raw ore pulp, then terpineol oil is added and stirred for 90s, the amount of terpineol oil added is 20g / t of raw ore pulp, and then reverse flotation roughing is carried out for 4min to separate the tailings containing calcium. obtain crude concentrate;

[0049] The coarse co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com