Digestion-desliming-reverse flotation method for processing low-grade high-silicon and high-calcium magnesite

A high-calcium magnesite and reverse flotation technology, applied in flotation, grain treatment, solid separation, etc., can solve the problems of poor desiliconization selectivity of reverse flotation, complicated flotation process, etc., and achieve easy thickening and filtration operations, The effect of shortening the process flow and easy filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

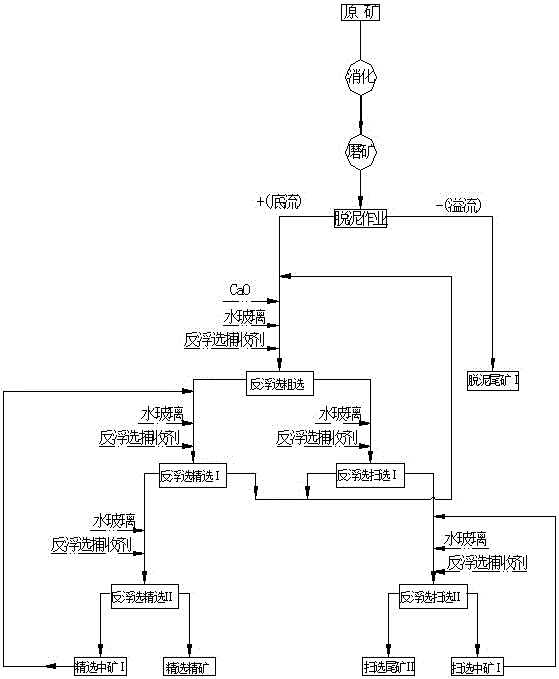

[0020] Embodiment 1, with reference to figure 1 , a digestion-desliming-reverse flotation method for processing low-grade high-silicon and high-calcium magnesite, the steps are as follows:

[0021] (1) Crushing low-grade, high-silicon and high-calcium magnesite raw ore to -12mm~-200mm, feeding the crushed material into a rotary kiln or fluidized bed furnace, and roasting at 450°C for 60 minutes;

[0022] (2) Grind the roasted material to -0.074mm by a ball mill, accounting for 70% of the total weight of all materials, and then add water to make raw ore pulp with a weight concentration of 20%;

[0023] (3) Put the raw ore pulp into the desliming cyclone to remove the -30μm~-10μm sludge;

[0024] (4) Put the deslimed ore pulp into the flotation equipment, under the condition of stirring speed of 1200rpm, first add the regulator sodium carbonate or CaO, adjust the pH value of the ore pulp to 8.5, then add water glass 600g / t, stir, Then add reverse flotation collector, stir, the...

Embodiment 2

[0025] Embodiment 2, with reference to figure 1 , a digestion-desliming-reverse flotation method for processing low-grade high-silicon and high-calcium magnesite, the steps are as follows:

[0026] (1) Crushing low-grade, high-silicon and high-calcium magnesite raw ore to -12mm~-200mm, feeding the crushed material into a rotary kiln or fluidized bed furnace, and roasting at 600°C for 20s;

[0027] (2) Grind the roasted material to -0.074mm by a ball mill, accounting for 95% of the total weight of all materials, and then add water to make raw ore pulp with a weight concentration of 40%;

[0028] (3) Put the raw ore pulp into the desliming cyclone to remove the -30μm~-10μm sludge;

[0029] (4) Put the deslimed ore pulp into the flotation equipment, under the condition of stirring speed of 1800rpm, first add the regulator sodium carbonate or CaO, adjust the pH value of the ore pulp to 12.0, then add water glass 6000g / t, stir, Then add reverse flotation collector, stir, the amou...

Embodiment 3

[0030] Embodiment 3, with reference to figure 1 , a digestion-desliming-reverse flotation method for processing low-grade high-silicon and high-calcium magnesite, the steps are as follows:

[0031] (1) Crushing low-grade, high-silicon and high-calcium magnesite raw ore to -12mm~-200mm, feeding the crushed material into a rotary kiln or fluidized bed furnace, and roasting at 500°C for 30 minutes;

[0032] (2) Grind the roasted material to -0.074mm by a ball mill, accounting for 85% of the total weight of the whole material, and then add water to make raw ore pulp with a weight concentration of 30%;

[0033] (3) Put the raw ore pulp into the desliming cyclone to remove the -30μm~-10μm sludge;

[0034] (4) Put the deslimed ore pulp into the flotation equipment, under the condition of stirring speed of 1600rpm, first add the regulator sodium carbonate or CaO, adjust the pH value of the ore pulp to 10.0, then add water glass 3000g / t, stir, Then add reverse flotation collector, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com