Automatic assembling technology for LED filament lamp

A technology for LED filament lamps and assembly processes, which is applied in the direction of lighting devices, light sources, semiconductor devices of light-emitting elements, etc., can solve problems such as low welding strength, low assembly efficiency of LED filament lamps, and complicated welding processes, so as to improve assembly efficiency, The effect of reducing the probability of assembly errors and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

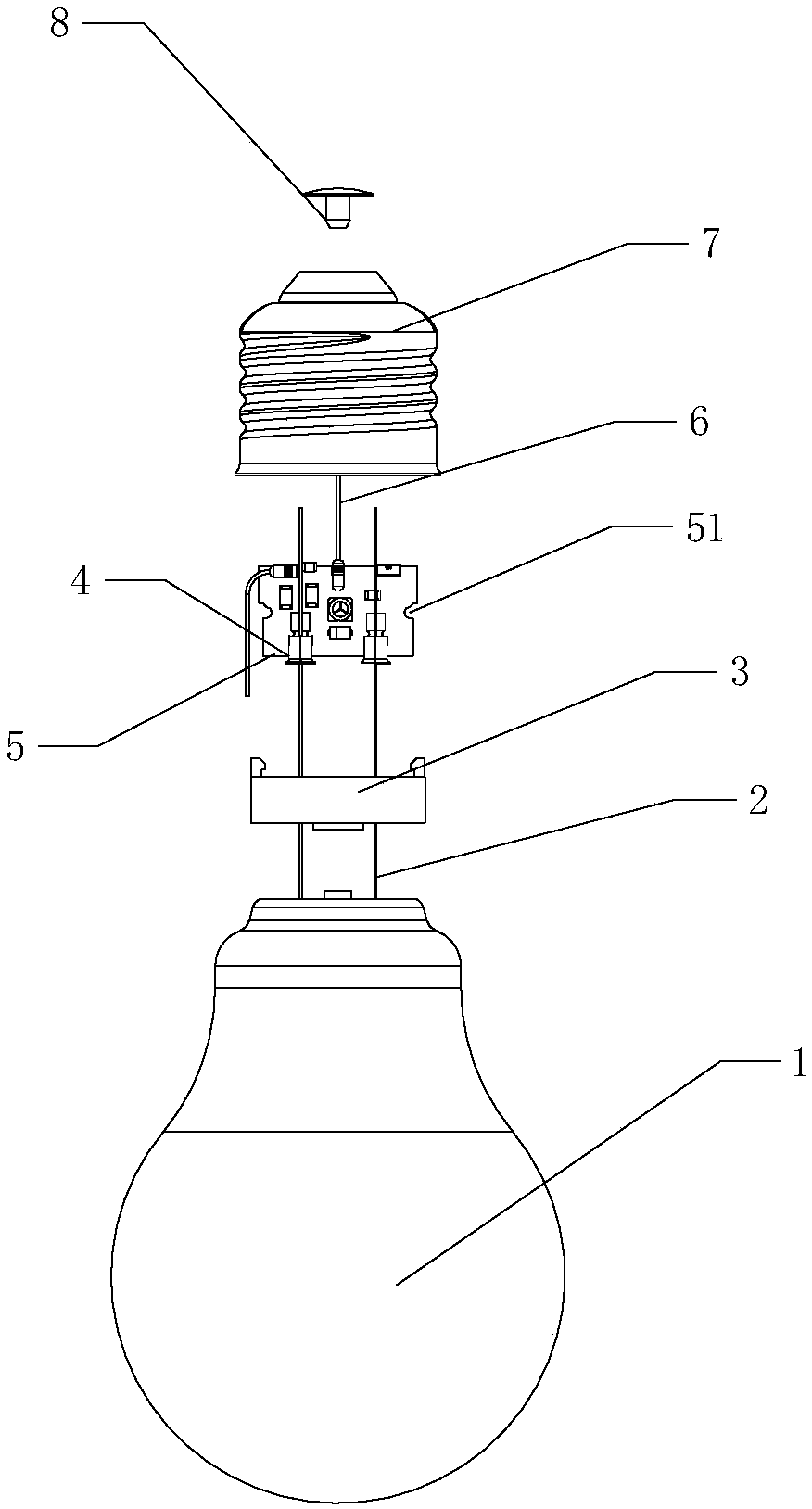

[0040] like figure 1 , Figure 3-7 In the shown embodiment, an LED filament lamp automatic assembly process, the specific flow of the assembly process is as follows:

[0041] The first station: first fix the glass bulb 1 in the fixture, then straighten the filament wire 2 with a robot, and then flow the fixed glass bulb 1 and the straightened filament wire 2 into the second station;

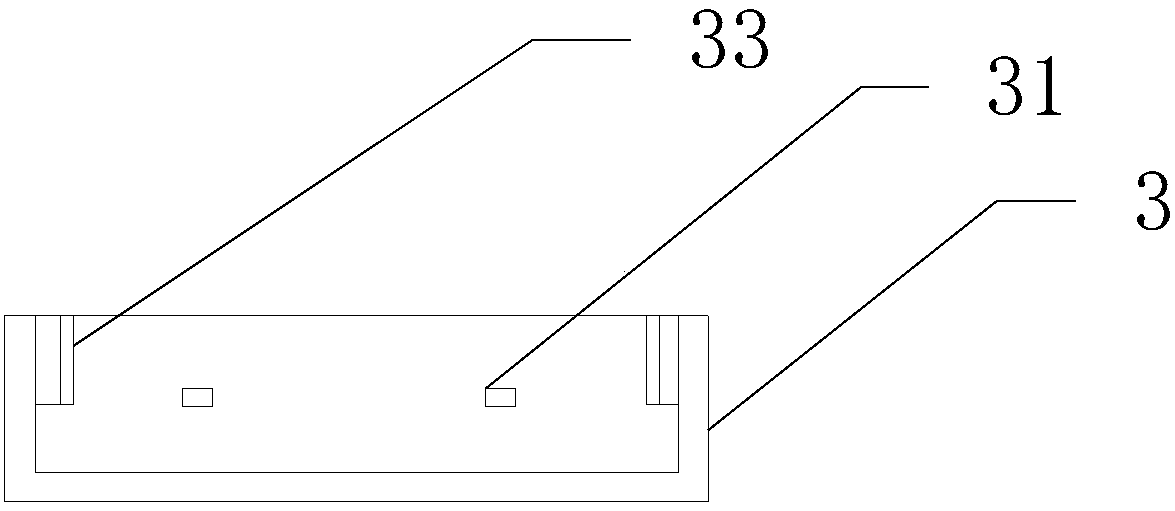

[0042]The second station: Use mechanical claws to grab the plastic support 3, pass the straightened filament wire 2 flowing in from the first station through the filament hole 31 in the plastic support 3, and place the plastic support 3 on the glass bulb 1 fixedly connected, and then flow into the third station; wherein the bottom end of the plastic support 3 is provided with a support buckle 32, and the end of the glass bulb 1 is provided with a support slot 13 matching the support buckle 32, and the support snaps Buckle 32 cooperates with bracket slot 13 so that plastic bracket 3 is fixedly c...

Embodiment 2

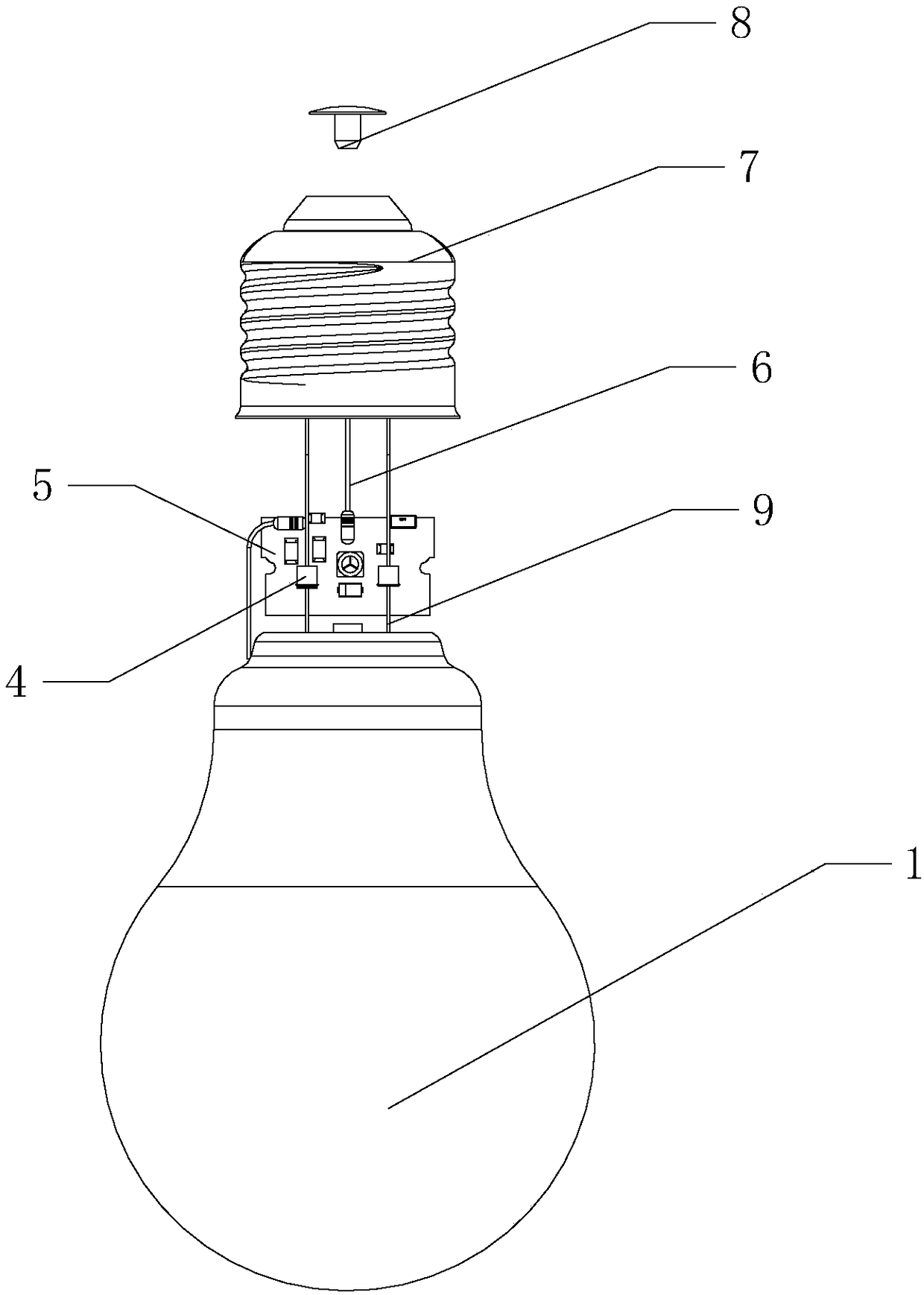

[0047] like figure 2 , Figure 5-7 In the shown embodiment, an LED filament lamp automatic assembly process, the specific flow of the assembly process is as follows:

[0048] The first station: first fix the glass bulb 1 in the fixture, and then flow into the second station;

[0049] The second station: manually weld the connector 4 to the drive assembly 5, then fix one end of the hard filament 9 to the connector 4, extend the other end into the glass bulb 1 and fix it, and cut off the excess The hard filament 9, then the whole flows into the third station;

[0050] The third station: Use mechanical claws to grab the lamp cap 7, apply glue inside the lamp cap 7, fix the lamp cap 7 and the glass bulb 1 to form a whole, cut off the redundant output line 6, and then install the lamp cap The thumbtack 8 flows into the fourth station; the end of the lamp cap 7 near the glass bulb 1 is provided with a lamp cap buckle 71 passing through the lamp cap 7, and the number of the lamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com