Pin-type gripper device

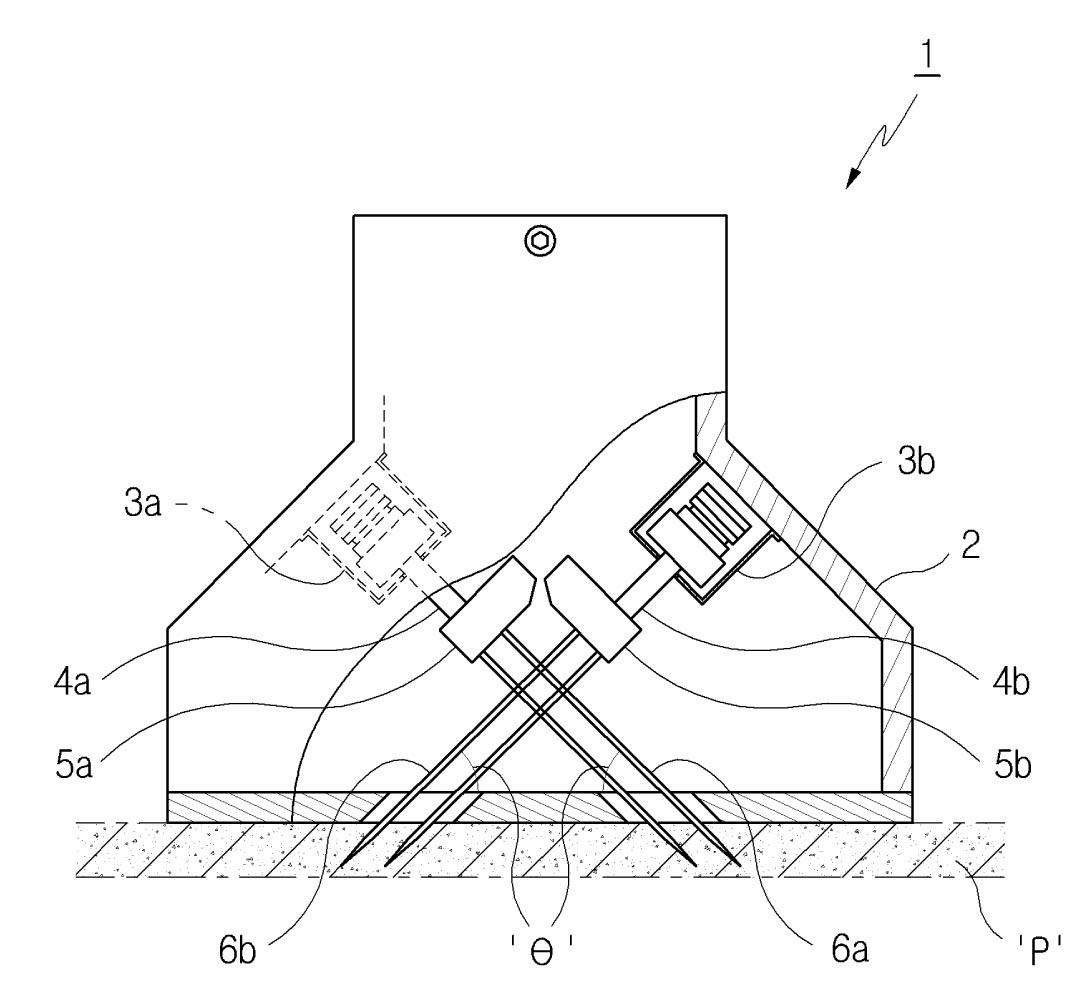

A fixture device and nail-type technology, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of large device scale, increased probability of failure and error, high cost and time, etc., and achieves simple structure and control. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

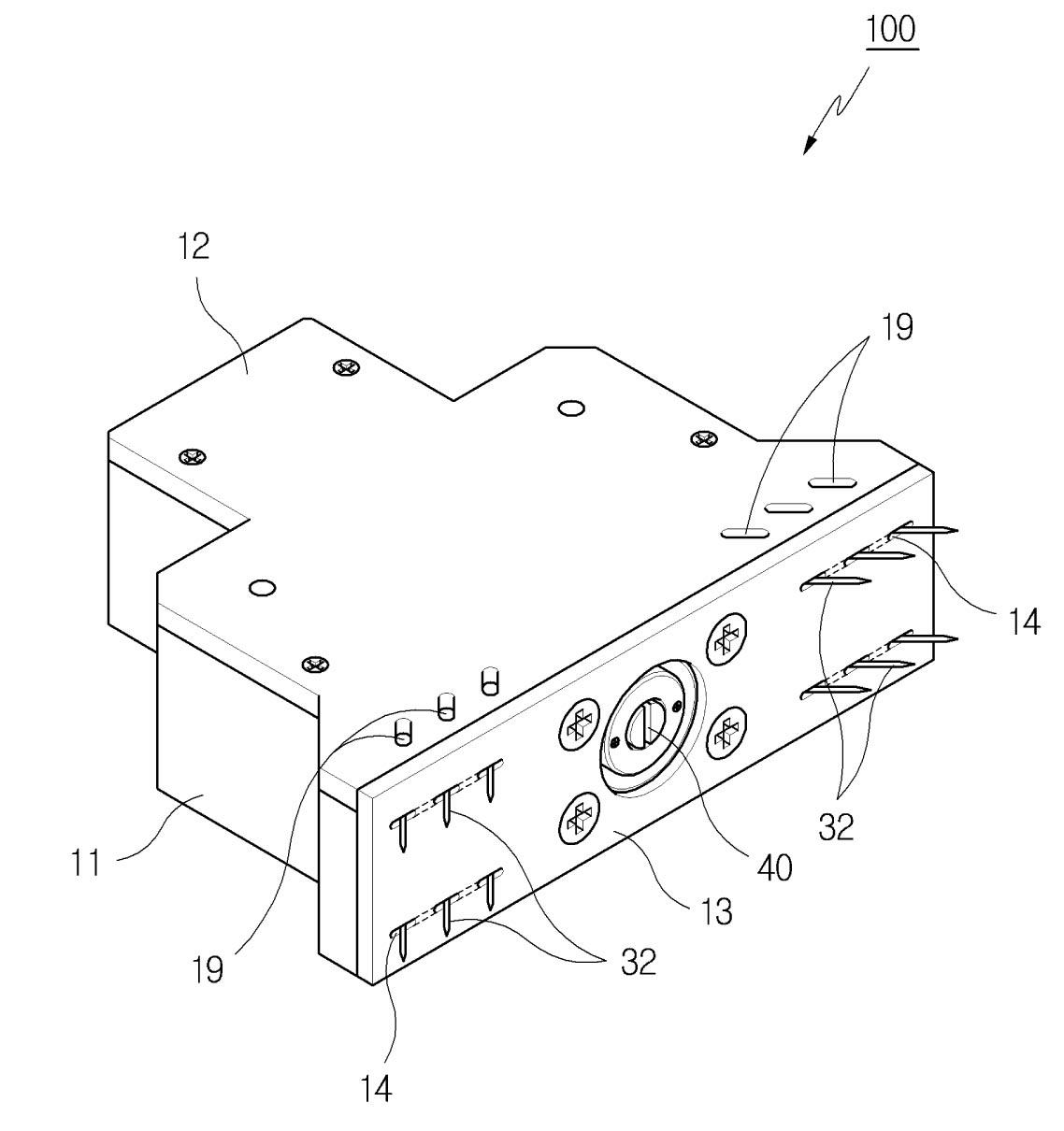

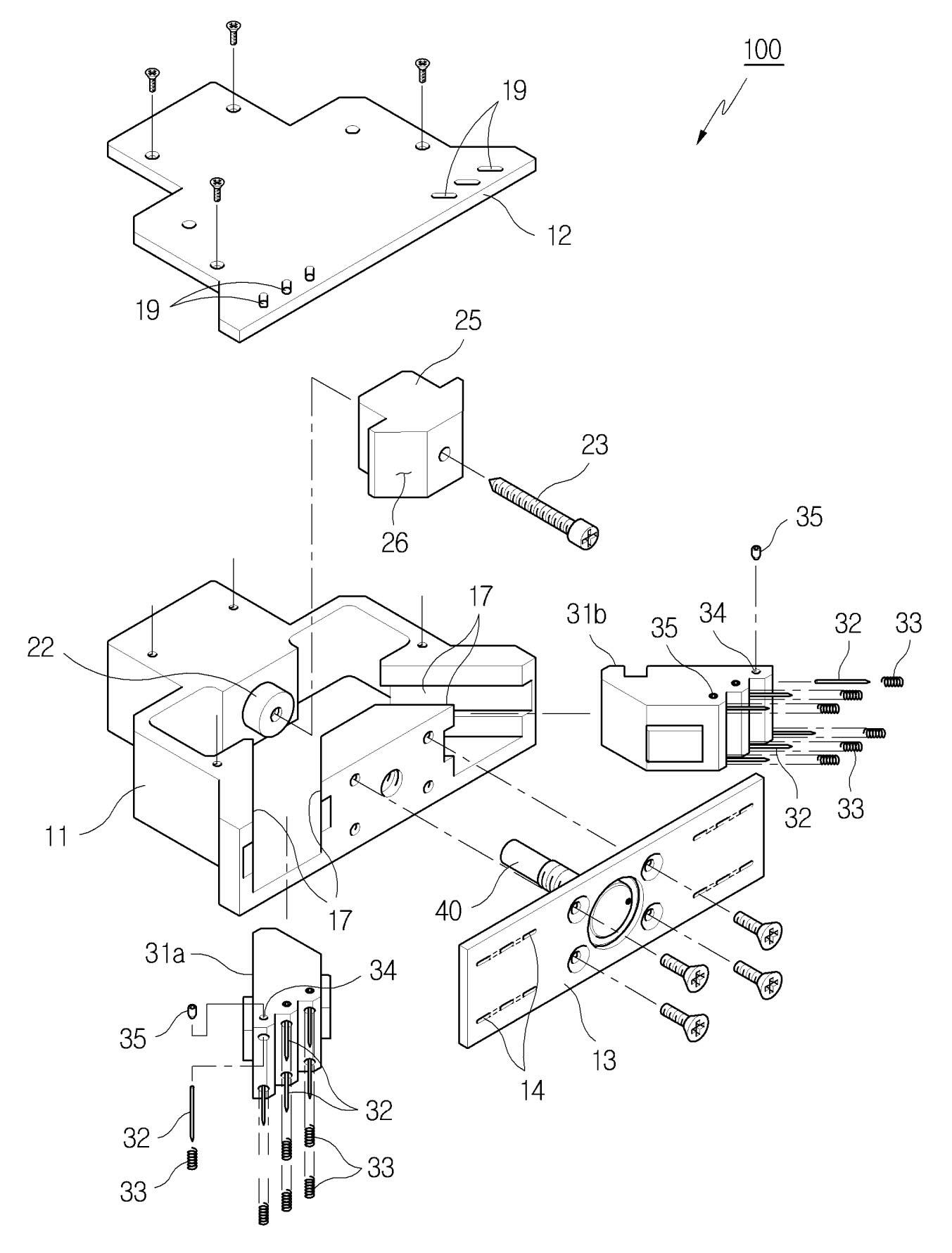

[0034] The features and effects of the present invention described or not described above will be further illustrated by the embodiments described below with reference to the accompanying drawings. figure 2 In the subsequent drawings, the nail clamp device of the present invention is indicated by the symbol 100.

[0035] Reference Figure 2 to Figure 4 It can be seen that the nail clamp device (100) of the present invention includes an outer cover (10), an air cylinder unit (20) organically arranged in the outer cover (10), and a running part (30). The number of the pump unit (10) provided in the device (100) of the present invention is only one.

[0036] The body (11) of the outer cover (10) is provided with an internal space that can ensure the most suitable installation and movement of the air cylinder unit (20) and the operating part (30). The body (11) is closed by a cover plate (12) and a bottom plate (13). The bottom plate (13) is the bottom surface of the outer cover (10)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com