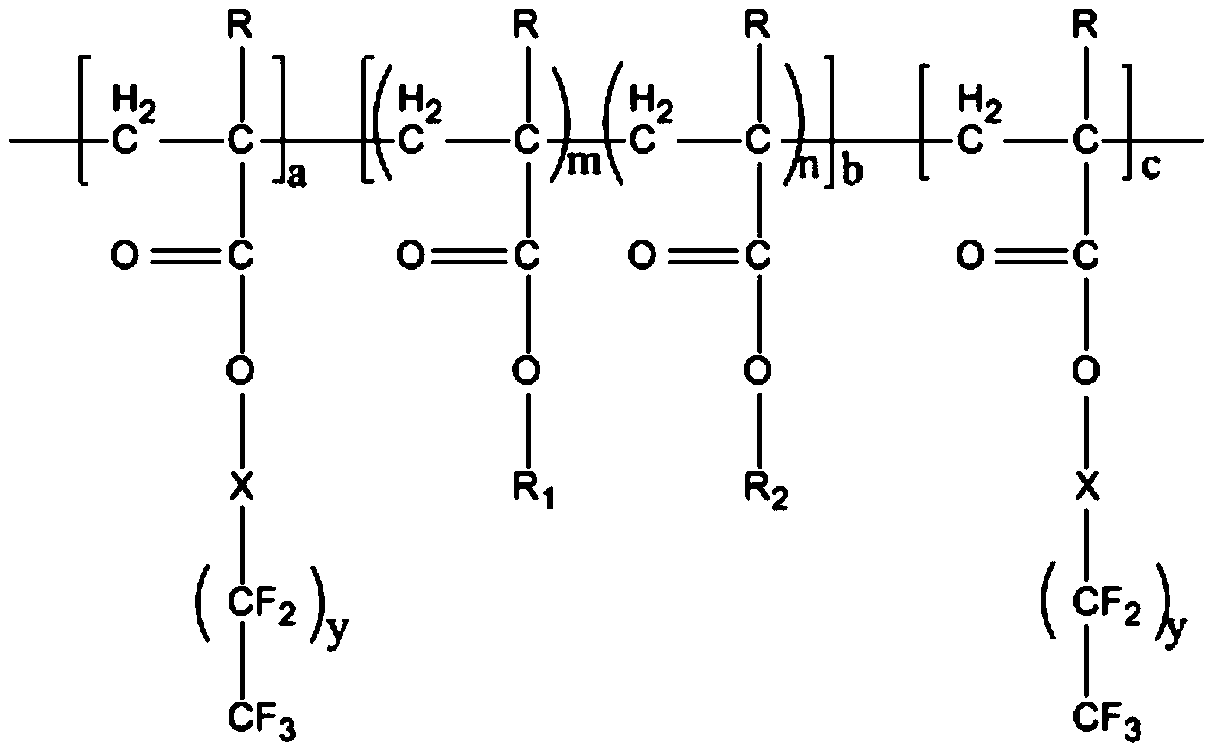

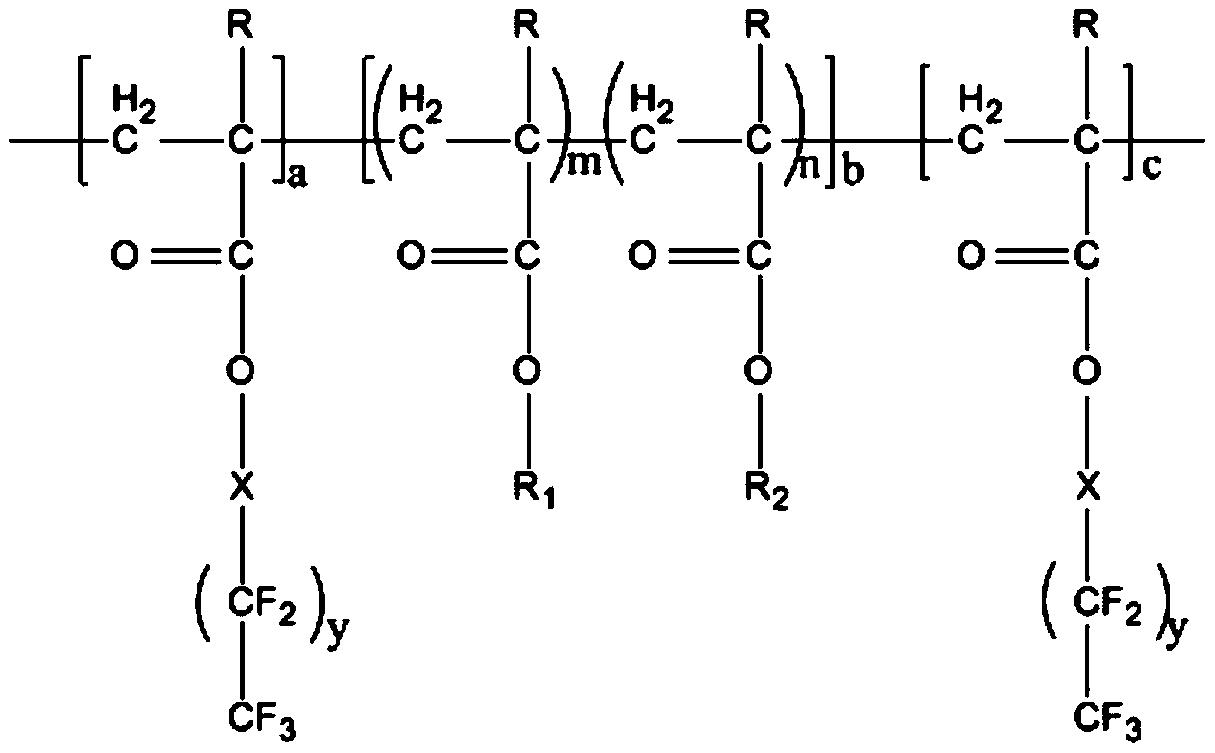

Multi-component triblock fluorosilicone copolymer electronic protective agent with sequence structure and preparation method thereof

A technology of fluorine-silicon copolymer and three-block, which is applied in the field of multi-component tri-block fluorine-silicon copolymer electronic protective agent and its preparation, and can solve the problems of high fluorine monomer content, difficult coating, and low coating efficiency , to achieve the effect of improving the overall performance, improving the hydrophobic and oleophobic properties of the surface, and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

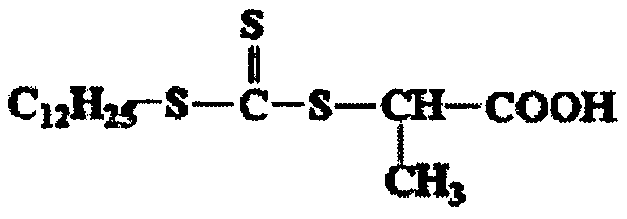

[0024] 0.3 g of RAFT reagent 2-[(dodecylsulfanyl)thioacyl]-sulfanyl propionic acid, 0.5 g of 3-trimethoxysilane propyl acrylate, and 10 g of butyl acrylate were mixed with 21 g of perfluorohexanone Mix evenly, raise the temperature to 60°C, add 0.08 g of initiator AIBN, and keep the reaction in a nitrogen atmosphere for 5 hours to obtain a prepolymer with active groups at both ends. At this temperature, a mixed solution composed of 6 g of perfluorobutyl ethyl acrylate and 18 g of perfluorohexanone was added dropwise to carry out a block copolymerization reaction. The dropping time was 4 hours. After cooling to room temperature, a fluorosilicone triblock copolymer solution can be obtained.

Embodiment 2

[0026] 0.35 g of RAFT reagent 2-[(dodecylsulfanyl)thioacyl]-sulfanylpropionic acid, 1.0 g of 3-(methacryloyloxy)propyl]trimethoxysilane, methacrylic acid Mix 8 g of isooctyl ester with 20 g of hydrofluoroether evenly, raise the temperature to 58°C, add 0.10 g of initiator azobisisoheptanonitrile, and keep it in a nitrogen atmosphere for 6 hours to obtain a prepolymerized compound with active groups at both ends. things. At this temperature, a mixed solution consisting of 8 g of trifluorooctyl methacrylate and 20 g of hydrofluoroether was added dropwise to carry out a block copolymerization reaction. The dropwise addition time was 3 hours. After cooling to room temperature, a fluorosilicone triblock copolymer solution can be obtained.

Embodiment 3

[0028]0.4 g of RAFT reagent 2-[(dodecylsulfanyl)thioacyl]-sulfanyl propionic acid, 1 g of 3-acryloyloxypropyltriethoxysilane, and 8 g of hexyl acrylate were mixed with 25 g of six Fluorotoluene was mixed evenly, the temperature was raised to 68°C, 0.08 g of dimethyl azobisisobutyrate was added as an initiator, and the reaction was maintained for 4 hours in a nitrogen atmosphere to obtain a prepolymer with active groups at both ends. At this temperature, a mixed solution composed of 5 g of perfluorohexylethyl acrylate and 16 g of hexafluorotoluene was added dropwise to carry out block copolymerization reaction. The time for the addition was 4 hours. Fluorosilicone triblock copolymer solution can be obtained at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com