Pulverized Anthracite modifying agent and coal blending and coking method using same

A coking technology of anthracite coal powder and coal blending, which is applied in the field of anthracite coal powder modifiers and coal blending coking, can solve the problems of poor coke quality and unsatisfactory coke, and achieve reduced coking costs, significant economic benefits, and saving coking coal resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of anthracite coal powder modifier: make coal powder modifier in the amount of 1kg, boric acid accounts for 60% of the weight of coal powder modifier in acidic substances, α-alanine 10%; Dialkyl dimethyl benzyl ammonium chloride accounts for 5% of the weight of the coal powder modifier, cationic cellulose polymer accounts for 10%; 10% by weight, and calcium-based bentonite accounts for 5% by weight of the coal powder modifier, which is ground and mixed uniformly;

[0035] Anthracite pulverized coal modification: take 0.4 kg of the above-mentioned pulverized coal modifier (accounting for 0.4‰ of the weight of the coking coal blend), and 50 kg of anthracite (accounting for 5% of the weight of the coking blend coal), and put them into a reformer with an automatic heating device Fully mix, react, and modify, the temperature in the modifier is controlled at 35°C, and the reaction time is 20 minutes;

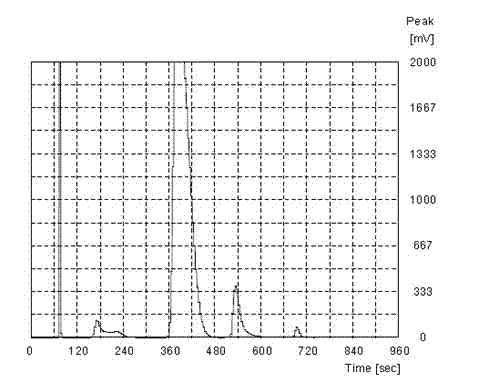

[0036] Coal blending and coking: Take 50 kg of the above-ment...

Embodiment 2

[0039] The preparation of anthracite coal powder modifier: make coal powder modifier with the amount of 2kg, boric acid accounts for 55% of coal powder modifier weight, malonic acid 10%, azelaic acid 5% in acidic substance; Dodecyl dimethyl benzyl ammonium chloride accounts for 10% of the weight of the coal powder modifier, and cationic cellulose polymer accounts for 6% of the weight of the coal powder modifier; dicyclohexyl phthalate accounts for 6% of the weight of the coal powder 10% of the weight of the coal powder modifier, calcium-based bentonite accounts for 4% of the weight of the coal powder modifier, put into a ball mill and mix evenly through ball milling;

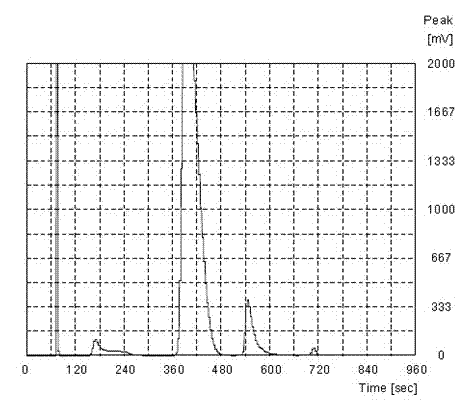

[0040] Anthracite pulverized coal modification: Take 2 kg of the above-mentioned pulverized coal modifier (accounting for 2‰ of the weight of the coking coal blend), and 100 kg of anthracite (accounting for 10% of the weight of the coking blend coal), and put them into the reformer with an automatic heating devic...

Embodiment 3

[0044] Preparation of anthracite coal powder modifier: make coal powder modifier in the amount of 5kg, boric acid accounts for 50% of coal powder modifier weight, azelaic acid accounts for 2%, a-alanine accounts for 10% of the weight of the coal powder modifier in acidic substances %; in surface active substances, dodecyl dimethyl benzyl ammonium chloride accounts for 8% of the weight of coal powder modifier, cationic cellulose polymer accounts for 5%, sodium stearate lactate accounts for 5%; plasticizer substances Dicyclohexyl phthalate accounts for 7% of the weight of the coal powder modifier, triphenyl phosphate 10%; calcium-based bentonite 3%, put into a ball mill, ball mill, and mix evenly;

[0045] Anthracite pulverized coal modification: Take 5 kg of the above-mentioned pulverized coal modifier (accounting for 5‰ of the weight of coking coal blend), 150 kg of anthracite (accounting for 15% of the weight of coking blend coal), and put them into the reformer with automatic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| abrasion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com