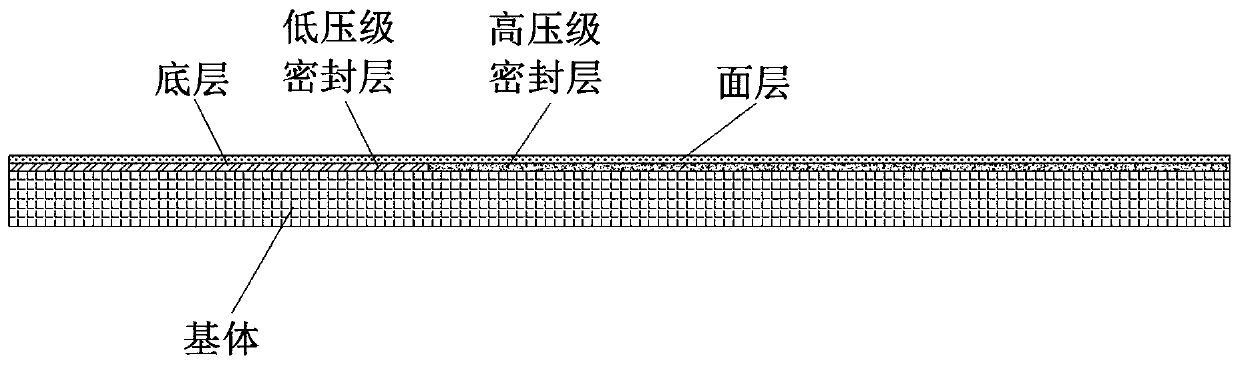

Coal-gas-corrosion-resistant gradient sealing coating structure and preparation method thereof

A technology of sealing coating and sealing layer, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of sealing layer damage and falling off, shortening the service life of sealing coating, etc., to increase the bonding strength and meet the requirements of Anti-corrosion of gas pollutants, effect of improving thickness and bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of a gas corrosion-resistant gradient seal coating structure, comprising the following steps:

[0047] S1. Preparation of matrix: Manganese, chromium, silicon, nickel, copper, niobium and iron are mixed and smelted in proportion, and cooled to obtain Cr which is resistant to tar, naphthalene, benzene and sulfide corrosion 17 Ni 4 Cu 4 Nb corrosion-resistant steel, in terms of mass percentage, the corrosion-resistant steel is prepared from the following raw materials: manganese: 0-1%; chromium: 15.5-17.5%; silicon: 0-1%; nickel: 3-5% ; Copper: 3-5%; Niobium: 0.15-0.45%; the balance is iron;

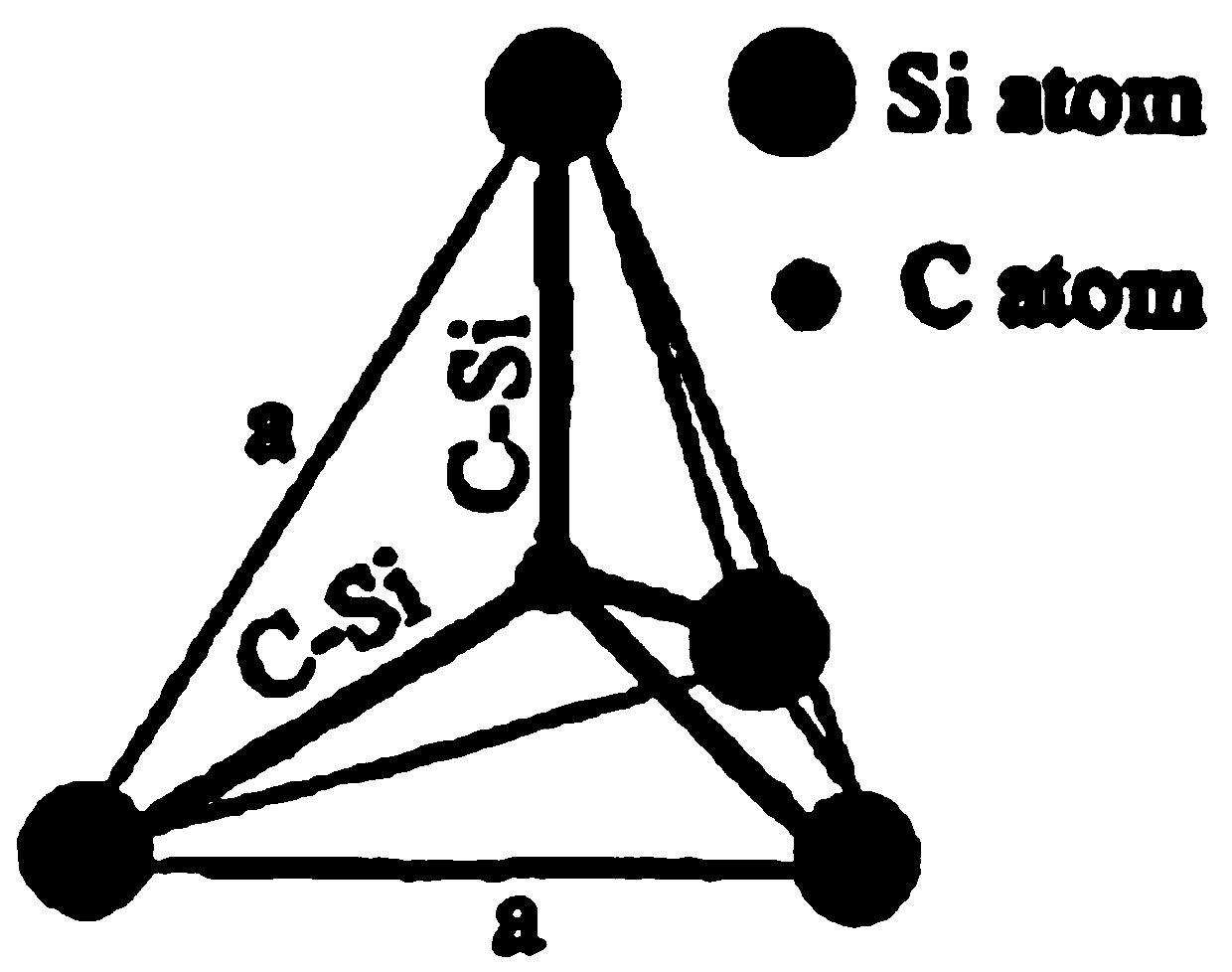

[0048] S2. Prepare the bottom layer: wrap a layer of aluminum metal particles on the surface of the nickel to obtain a nickel-aluminum mixed powder with complete coating and good structure uniformity. In the nickel-aluminum mixed powder, the mass percentage of nickel and aluminum is: nickel The mass percentage is 75-85%, an...

Embodiment 1

[0059] The seal of a CCPP seven-stage gas compressor in a steel plant is taken as an example: the performance test of three types of sealing coatings with the substrate and transition layer material composition, the same spraying process as plasma spraying, and the surface layer material structure and composition.

[0060] Matrix The base material is corrosion-resistant steel; the bottom layer is nano-scale nickel-aluminum powder with complete coating and good uniformity. The percentage is 80%, and the aluminum mass percentage is 20%;

[0061] The material of the surface layer is a composite material of aluminum-silicon polyphenylene, the mass percentage of aluminum and silicon elements is 65%, the mass percentage of polyphenylene is 25%, and the mass percentage of Mo is 10%.

Embodiment 2

[0063] The seal of a CCPP seven-stage gas compressor in a steel plant is taken as an example: the performance test of three types of sealing coatings with the substrate and transition layer material composition, the same spraying process as plasma spraying, and the surface layer material structure and composition.

[0064] Matrix The base material is corrosion-resistant steel; the bottom layer is nano-scale nickel-aluminum powder with complete coating and good uniformity. The percentage is 3%, and the aluminum mass percentage is 3%;

[0065] The surface material is made of corrosion-resistant aluminum-silicon-graphite, the mass percentage of aluminum is 30%, the mass percentage of silicon is 35%, and the mass percentage of graphite is 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com