Cold-resistant seal ring based on graphene/polymer composite material and preparation method

A composite material, graphene technology, used in household components, applications, household appliances, etc., can solve problems such as particle size distribution deviation, poor cold resistance, affecting mud stability, etc., to ensure size, improve quality, and increase stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

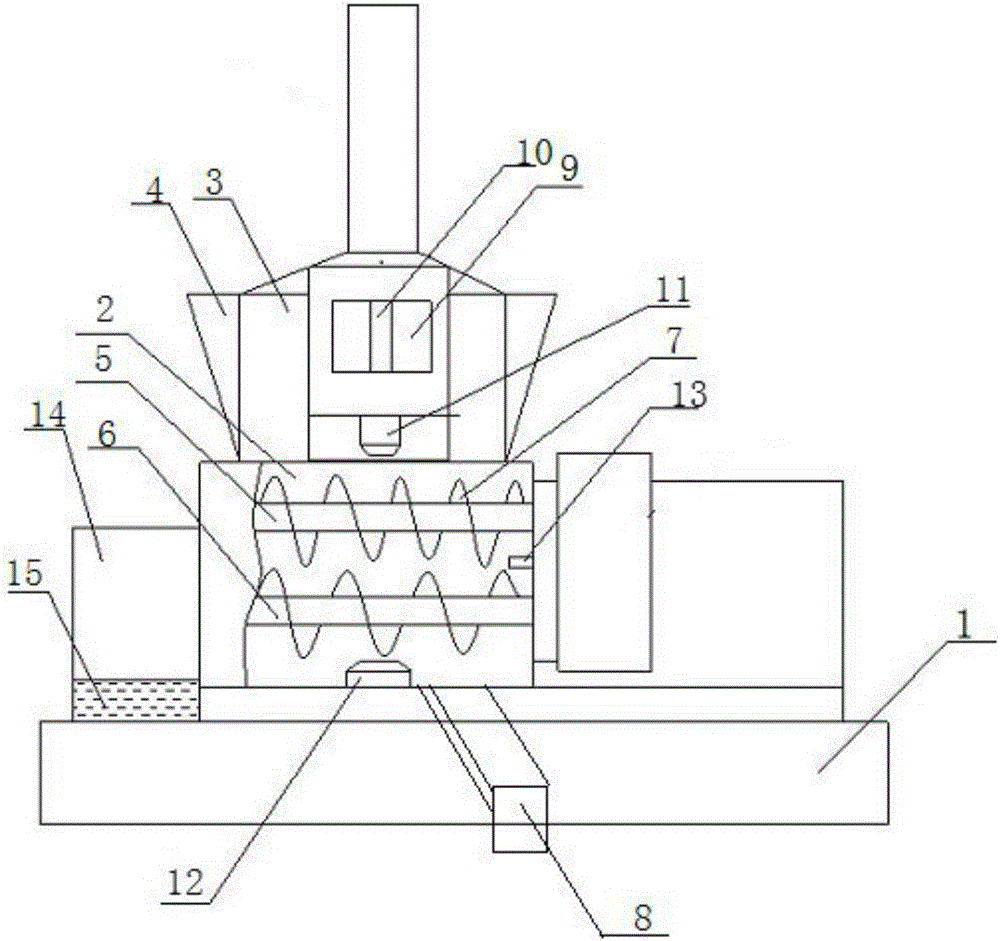

Image

Examples

Embodiment 1

[0028] A kind of cold-resistant sealing ring based on graphene / polymer composite material, this composite material is matrix with polymer, is filler with graphene, it is characterized in that, described polymer comprises by weight fraction: 100 parts of fluororubber; EO / PO block polyether 5 parts; active agent zinc oxide 15 parts; plasticizer dicyclohexyl phthalate 4 parts, anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinone 15 parts of morphine polymer, 9 parts of reinforcing agent phenolic resin; 20 parts of plasticizer dicyclohexyl phthalate; 3 parts of accelerator DETU; 10 parts of accelerator DPG; 0.6 part of sulfur; with graphene as filler, weight fraction for 18 servings.

[0029] A kind of preparation method of the cold-resistant sealing ring based on graphene / polymer composite material, comprises the following steps:

[0030] Step (1): Pour the graphene into the alcohol solution, prepare a suspension with a mass ratio of 1:10, and use an ultrasonic disperser to prep...

Embodiment 2

[0040] A kind of cold-resistant sealing ring based on graphene / polymer composite material, this composite material is matrix with polymer, is filler with graphene, it is characterized in that, described polymer comprises by weight fraction: 100 parts of fluororubber; EO 12 parts of / PO block polyether; 6 parts of active agent zinc oxide; 15 parts of plasticizer dicyclohexyl phthalate, anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinone 4 parts of morphine polymer, 16 parts of reinforcing agent phenolic resin; 12 parts of plasticizer dicyclohexyl phthalate; 10 parts of accelerator DETU; 3 parts of accelerator DPG; 1.2 parts of sulfur; with graphene as filler, weight fraction is 0.06 parts.

[0041] A kind of preparation method of the cold-resistant sealing ring based on graphene / polymer composite material, comprises the following steps:

[0042] Step (1): Pour the graphene into the alcohol solution, prepare a suspension with a mass ratio of 1:50, and use an ultrasonic disperse...

Embodiment 3

[0052] A kind of cold-resistant sealing ring based on graphene / polymer composite material, this composite material is matrix with polymer, is filler with graphene, it is characterized in that, described polymer comprises by weight fraction: 100 parts of fluororubber; EO 8 parts of / PO block polyether; 12 parts of active agent zinc oxide; 6 parts of plasticizer dicyclohexyl phthalate, anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinone 12 parts of morphine polymer, 12 parts of reinforcing agent phenolic resin; 18 parts of plasticizer dicyclohexyl phthalate; 5 parts of accelerator DETU; 8 parts of accelerator DPG; 0.8 part of sulfur; with graphene as filler, weight fraction Makes 12 servings.

[0053] A kind of preparation method of the cold-resistant sealing ring based on graphene / polymer composite material, comprises the following steps:

[0054] Step (1): Pour the graphene into the alcohol solution, prepare a suspension with a mass ratio of 1:10, and use an ultrasonic disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com