Heat-dissipating coating for LED lamp and preparation method thereof

A technology of LED lamps and heat-dissipating coatings, applied in the direction of epoxy resin coatings, coatings, etc., can solve problems such as troubles and low luminous efficiency, and achieve the effects of solving heat dissipation problems, high thermal conductivity, and large heat dissipation surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further explained through specific implementations below.

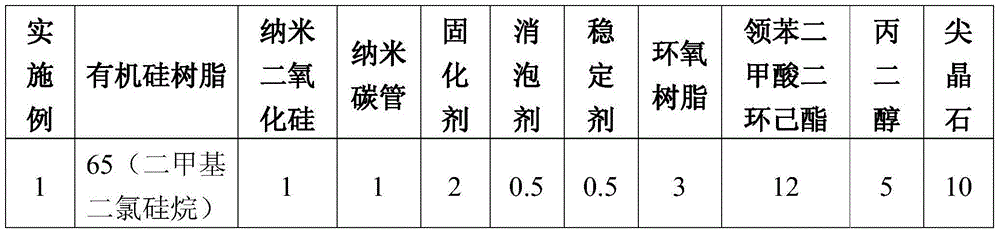

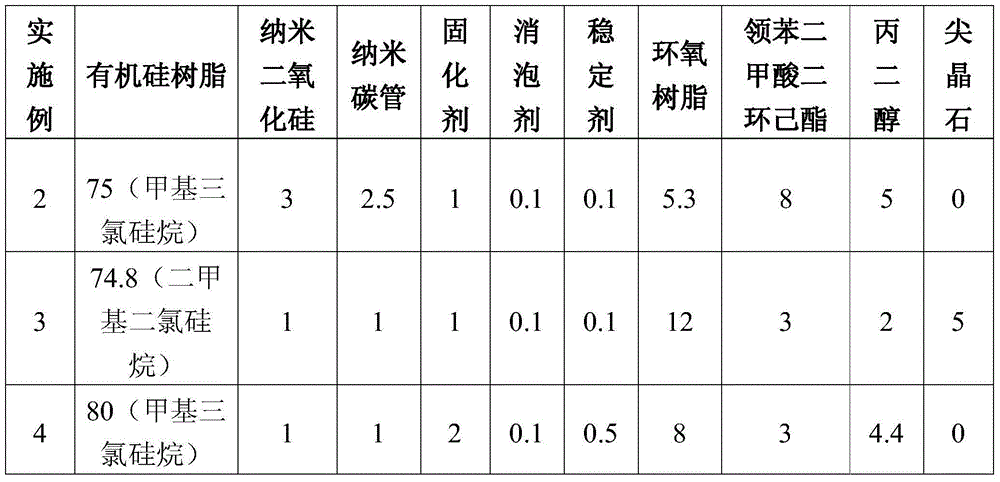

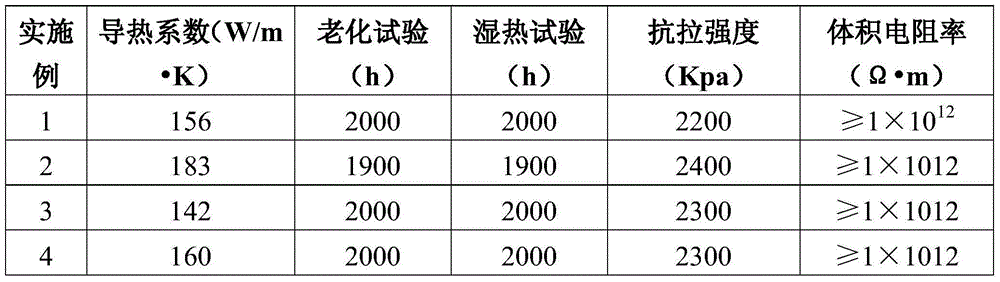

[0019] A heat-dissipating paint for LED lamps, which is prepared from the following raw materials in parts by weight: 65-80 parts by weight of organic silicon resin, 1-3 parts of nano-silica, 1-2.5 parts of carbon nanotubes, and 1-2 parts of curing agent Parts, 0.1~0.5 parts defoamer, 0.1~0.5 parts stabilizer, 3-12 parts epoxy resin, 3-12 parts dicyclohexyl phthalate, 2-5 parts propylene glycol; the silicone resin is One of dimethyldichlorosilane or methyltrichlorosilane.

[0020] Preferably, the carbon nanotubes are multi-walled carbon nanotubes, with a tensile strength of 10-60 GPa, an electrical conductivity of 106S / m, and a thermal conductivity of> 3000W / m·K, pipe diameter 12~15nm, length 3~15um,

[0021] The above-mentioned carbon nanotubes are multi-wall carbon nanotubes, and the specifications require elastic modulus 1 TPa, and the number of layers is 8-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com