Ageing resistant power line sheath material and preparation method thereof

A technology for power cords and sheathing materials, applied in circuits, electrical components, insulated cables, etc., can solve the problems of poor anti-aging properties, affecting the work of power cords, easy aging and cracking, etc., achieving strong anti-aging properties and wide operating temperature. , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

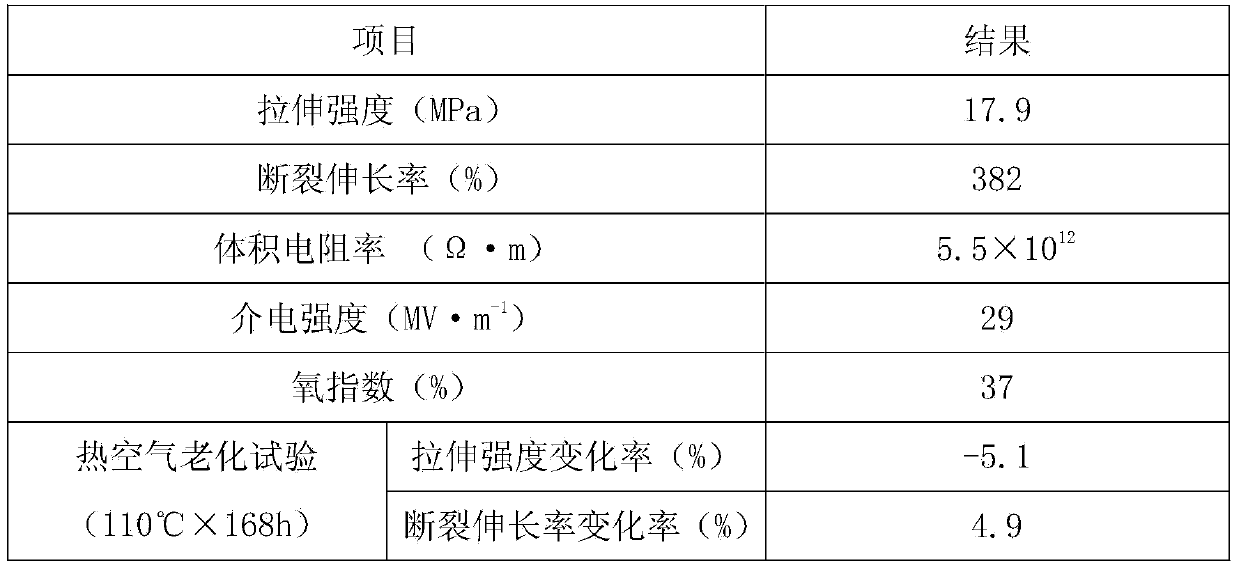

Examples

Embodiment Construction

[0010] An anti-aging power cord sheath material, made of the following raw materials in parts by weight: ultra-high molecular weight polyethylene 55, neoprene rubber 30, polybutylene terephthalate 15, vinyltrimethoxysilane 2, super Dicumyl oxide 2.5, basic magnesium carbonate 6, nano-kaolin 26, glass beads 22, glyceryl monoricinoleate 4, di-n-butyl nylon acid 12, dicyclohexyl phthalate 12, m-benzene Diphenol bis (diphenyl phosphate) 7, tris (2,3-dibromopropyl) isocyanurate 8, dibasic lead phosphite 1.5, calcium stearate 1, barium stearate 1, Paraffin oil 5, tetramethylthiuram monosulfide 1, 2-mercaptobenzothiazole 1.5, additive 24;

[0011] The preparation method of the auxiliary agent is as follows: a, take the following raw materials in parts by weight: siliceous shale 25, apatite 20, lapis lazuli 12, salicylanilide 3, tert-butyl chromate 2, diphenyl disulfide Dithiazole 1.5, zinc ethyl phenyl dithiocarbamate 2, hexachlorocyclotriphosphazene 8, barium metaborate 4, mica pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com