Production of diesel fuel from renewable feedstocks containing phosphorus

a technology of renewable feedstocks and diesel fuel, which is applied in the direction of catalytic naphtha reforming, hydrocarbon oil treatment products, naphtha reforming, etc., can solve the problem of common contamination of phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

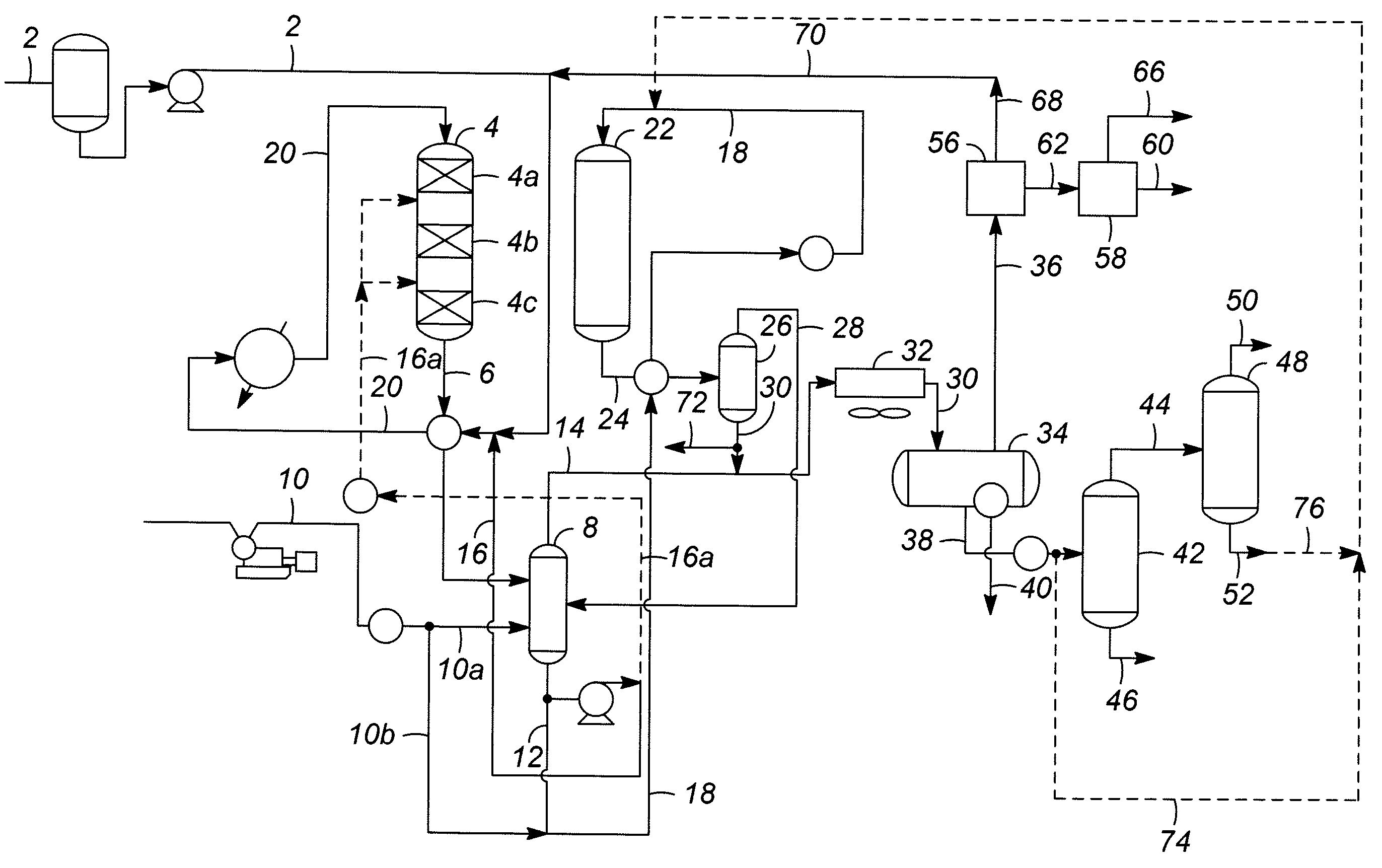

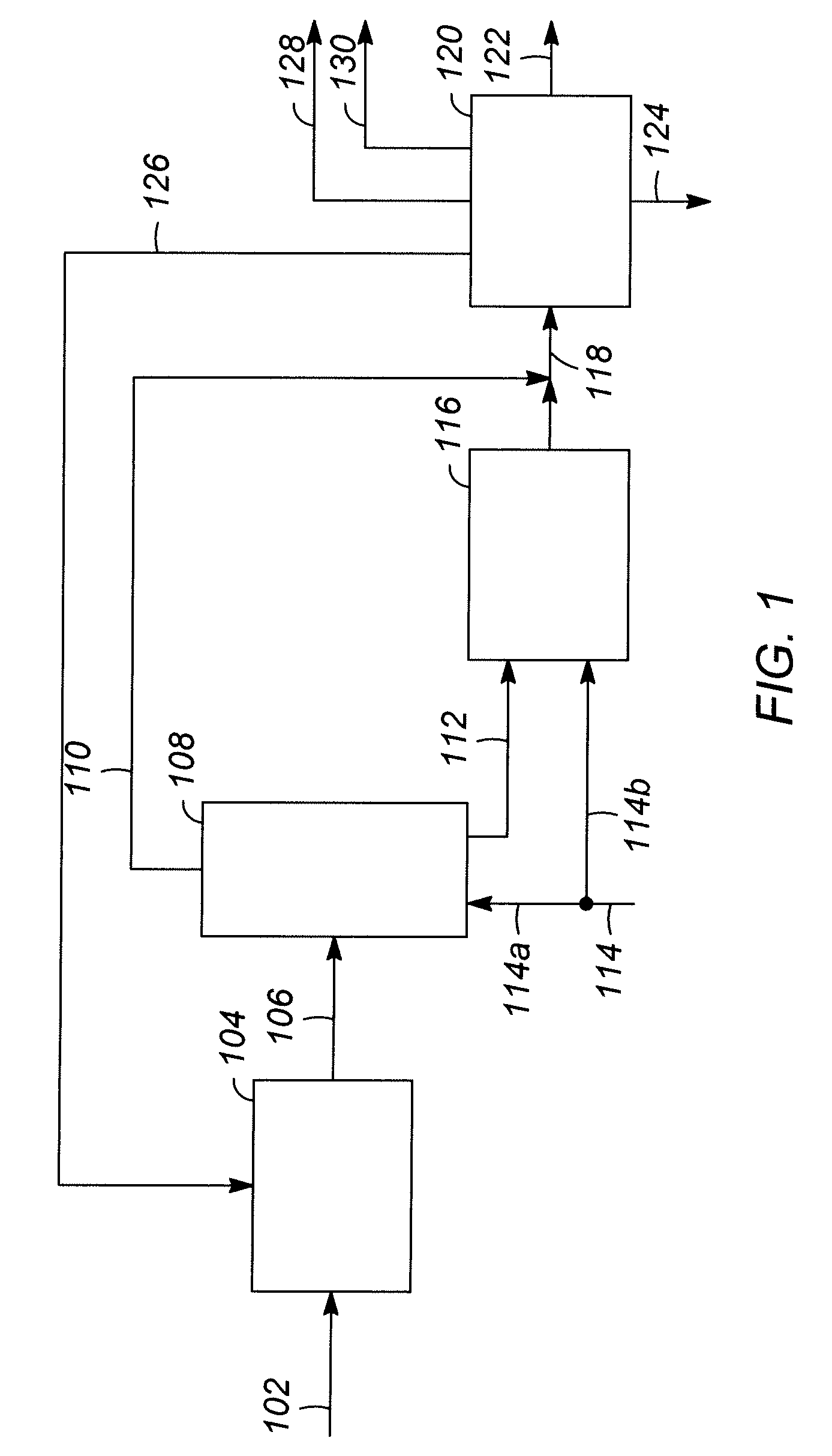

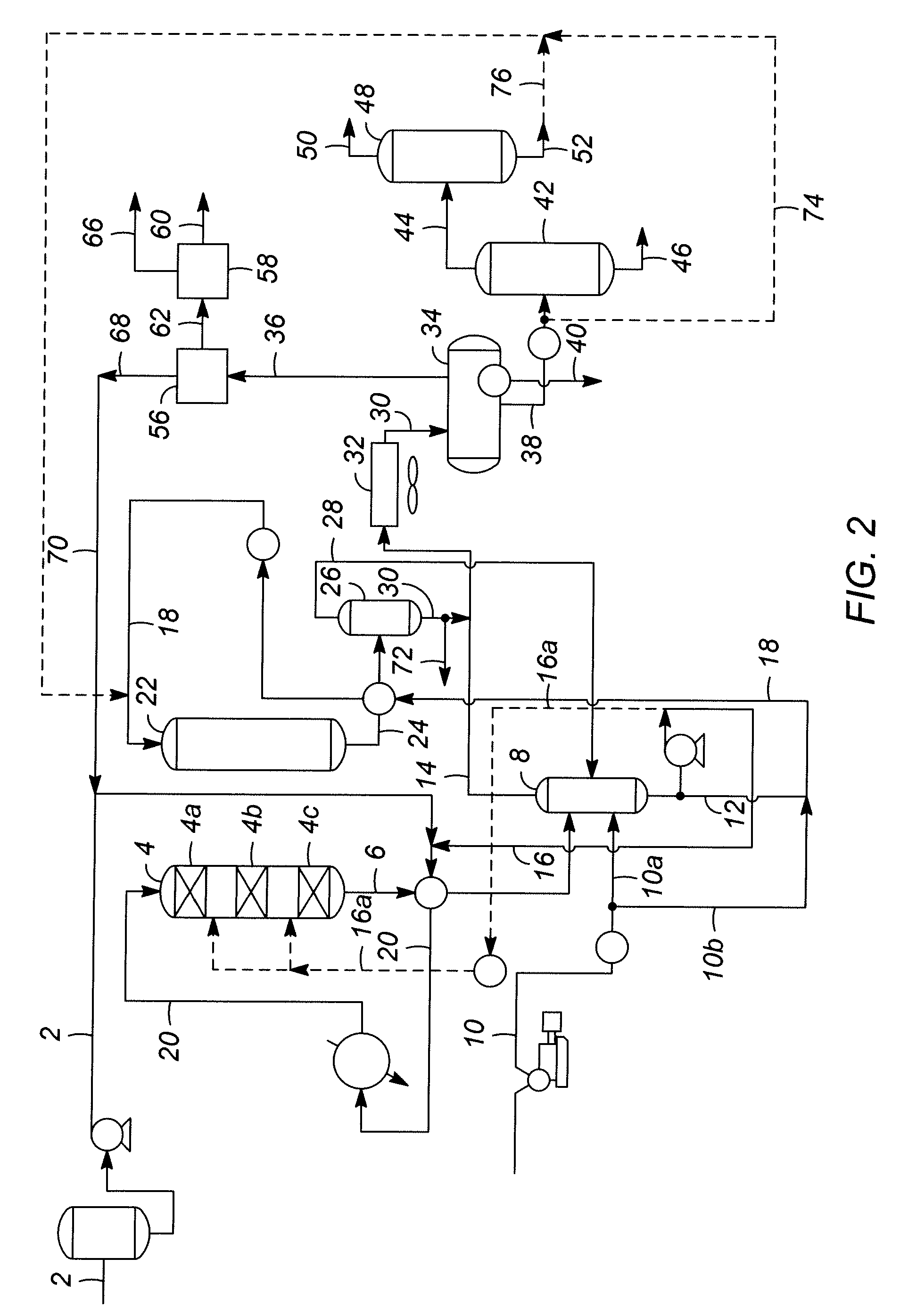

Method used

Image

Examples

example

[0034]Several renewable feedstocks, each having different levels of phosphorus were hydrogenated and deoxygenated (some were also isomerized), and the occurrence of plugging in the pre-heater or in the reactors was noted. Some of the experiments were conducted with a hydrocarbon recycle and some of the experiments were conducted without a hydrocarbon recycle. The renewable feedstocks tested included vegetable oils, grease, and tallow. For all cases except the yellow grease, the beef tallow, and the cooking oil, the feedstocks were processed at 1 LHSV with respect to fresh feedstock in a down-flow trickle bed reactor containing 150 cc of a promoted nickel-molybdenum on alumina catalyst. The feedstocks were continuously added at a rate of 150 cc / hr or 1LHSV over a period of 1000 hours at an operating pressure of about 3447 kPa absolute (500 psia) and about 310 to about 332° C. (590 to 650° F.). The H2 / hydrocarbon ratio in the feed was about 3700 to about 5000 scfb.

[0035]The Table show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| total pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com