Catalytic selective hydrogenation

A technology for selective hydrogenation and catalytic bed, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical stationary reactors, etc. Application technology and other issues to achieve the effect of shortening the reaction time, inhibiting side reactions, and eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

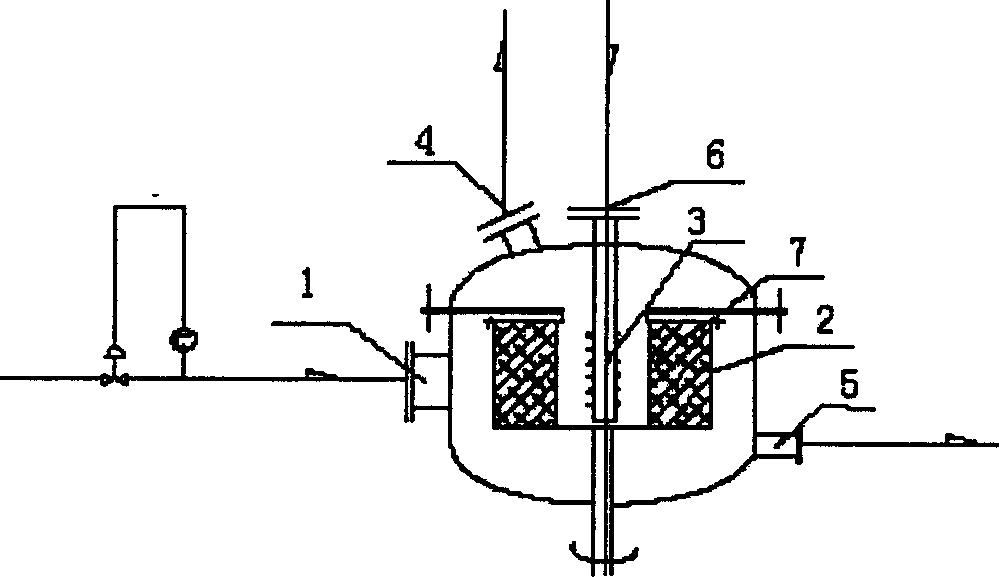

Image

Examples

Embodiment 1

[0042] Using a rotating bed reactor in a supergravity field for C 2 Selective hydrogenation of distillates to remove acetylene impurities. C 2 The acetylene content in the distillate is 1.0%, and the commercially available C 2 Select the hydrogenation catalyst (BC-H-21B) into the mesh support inner part (the catalyst is separated into a small grid of about 15 cm × 15 cm × 15 cm in the rotor with a 40-mesh stainless steel wire mesh), and fixed in the super The gravity field rotates on the rotor of the bed reactor. The C2 fraction and the hydrogen pass through the catalytic bed in a co-current manner.

[0043] Carry out the processing condition of selective hydrogenation reaction as follows:

[0044] Gas space velocity: 10000h -1 , Reaction temperature: 70°C, Reaction pressure: 2.0MPa

[0045] Hydrogen / Alkyne: 1.1mol / mol,

[0046] Rotor speed: 1250-1500rpm, catalytic bed radial thickness: 135mm

[0047] Select hydrogenation result:

[0048] Residual acetylene content in...

Embodiment 2

[0050] Using a rotating bed reactor in a supergravity field for C 4 Selective hydrogenation reaction of raffinate to remove butadiene. C 4 The raffinate contains C4-alkanes: 10-20%, C4-mono-olefins: 80-90%; C4-di-olefins: 0.5-2%. C 4 Selective hydrogenation catalyst (containing 0.2% Pd / Al 2 o 3 ) is prepared according to the method disclosed in CN1321544A, the catalyst is put into the ring-shaped supporting inner part, and fixed on the rotor of the high-gravity field rotating bed reactor. The ring-shaped supporting inner part is made of two rings with 4 mm stainless steel plate, supported by 6 mm stainless steel columns between the two rings, and the ring-shaped supporting inner part is formed, wherein the outer circle is made of 10 , 8 inner circles, the gap formed between the stainless steel pillars of the inner and outer circles is sealed with stainless steel wire mesh, and 4 small holes with a diameter of 25 mm are punched on the stainless steel plate of the upper cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com