Ore smashing and screening device for mining

A screening device and ore crushing technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of inability to layer sieve, inability to control the falling speed, etc., and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

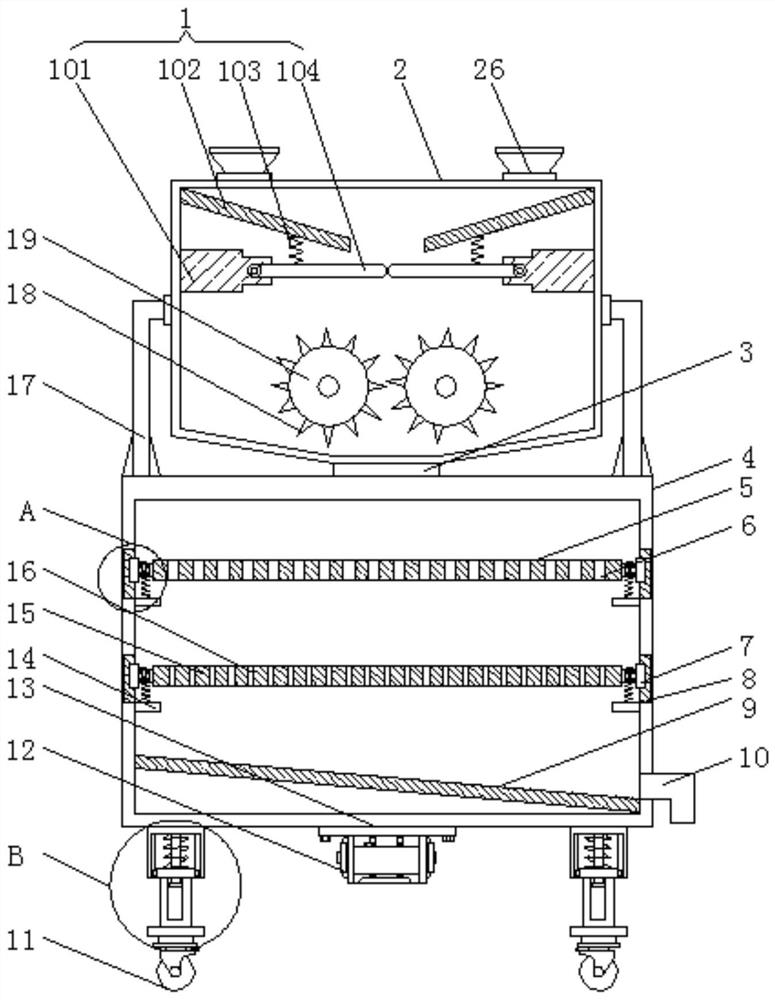

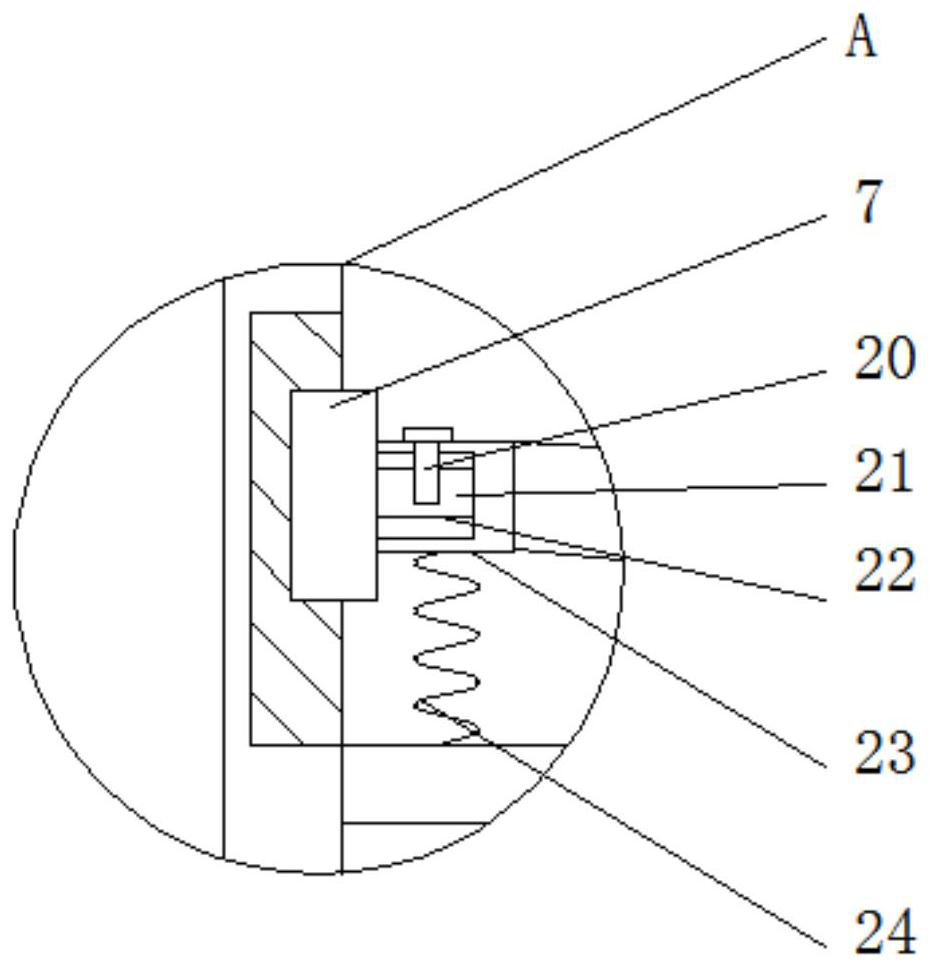

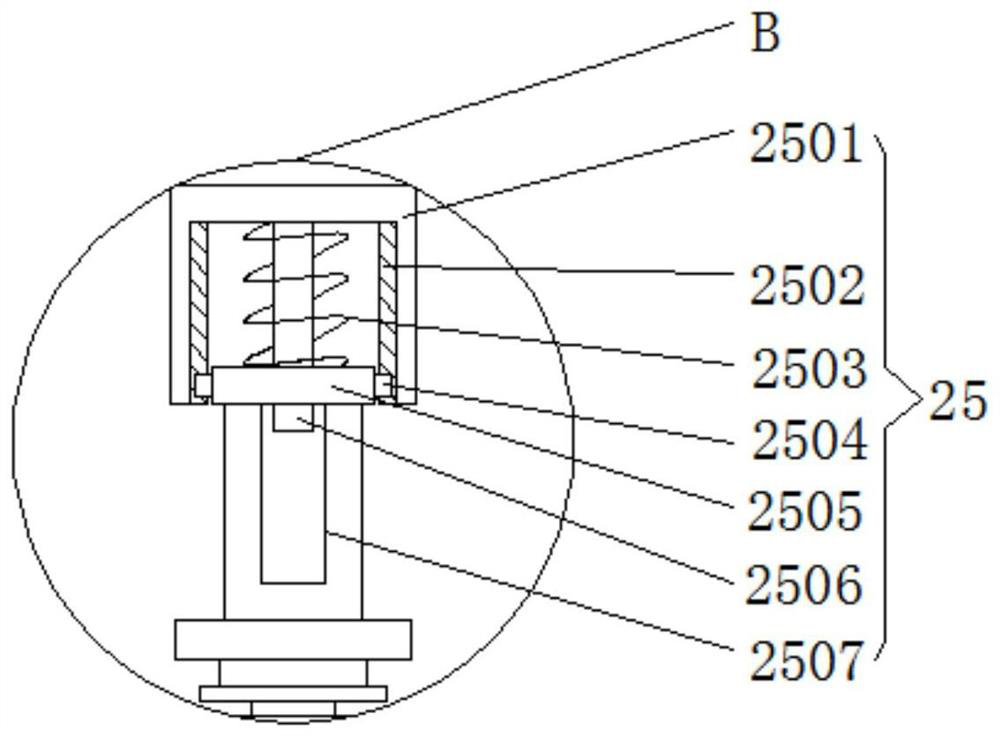

[0031] The present invention provides a technical solution: an ore crushing and screening device for mining, including a screening box 4, and a lifting mechanism 25 is installed at the four corners of the bottom of the screening box 4, and the lifting mechanism 25 includes a housing 2501, a slide Rail 2502, damping spring 2503, moving block 2504, movable plate 2505, vertical bar 2506 and cavity 2507, the housing 2501 of lifting mechanism 25 is positioned at the four corners of screening box 4 bottoms, the top of housing 2501 cavity A vertical rod 2506 is vertically installed, and slide rails 2502 are symmetrically provided at the left and right ends of the inner wall of the housing 2501. The inside of the slide rail 2502 is slidably installed with a moving block 2504, and a mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com