Production technology of fluorescent cotton fabric

A production process and technology of cotton fabrics, applied in the field of printing and dyeing, can solve the problems of unsatisfactory fluorescence durability and cotton fabrics cannot be dyed, and achieve the effect of excellent wearability, soft hand feeling and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

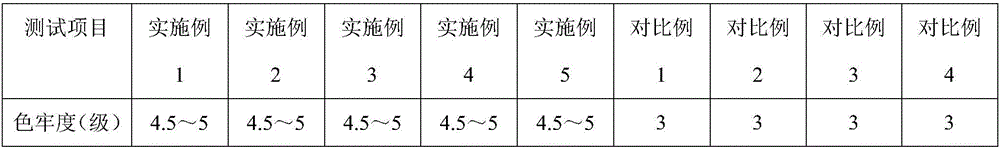

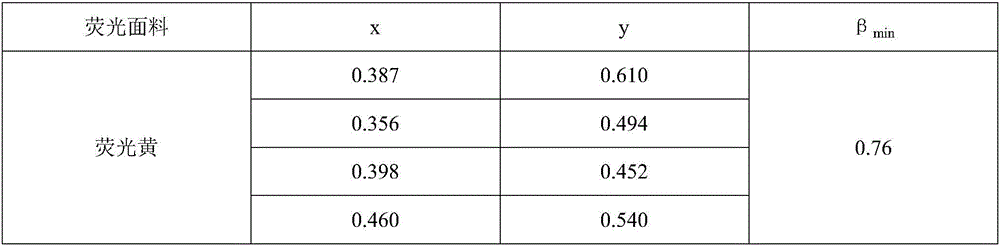

Examples

Embodiment 1

[0023] A kind of production technology of fluorescent cotton fabric of the present invention comprises steps:

[0024] (1) Modification of cotton fabric: immerse cotton fabric in 18g / L polyepichlorohydrin aminate solution, pH=10, bath ratio 30:1, initial temperature 30°C, rise to 5°C / min Keep at 70°C for 20 minutes, then rise to 90°C at 1°C / min and keep for 20 minutes, take it out, rinse with water, and dry at room temperature;

[0025] (2) Immerse in warm water at 60°C, soak for 30 minutes, take out, and dry at room temperature;

[0026] (3) Preparation of dyes: Add sodium carboxymethyl cellulose to water, stir for 12 hours, slowly add cationic dye fluorescent yellow X-10GFF300%, stir and mix well; cationic dye fluorescent yellow X-10GFF300%, carboxymethyl cellulose The mass ratio of sodium and water is 1:0.1:89;

[0027] (4) Fluorescent dyeing: immerse the cotton fabric treated in step (2) in the dye prepared in step (3) for dyeing, pH=5, bath ratio 30:1, initial temperatu...

Embodiment 2

[0029] A kind of production technology of fluorescent cotton fabric of the present invention comprises steps:

[0030] (1) Modification of cotton fabric: immerse cotton fabric in 18g / L polyepichlorohydrin aminate solution, pH=10, bath ratio 30:1, initial temperature 30°C, rise to 5°C / min Keep at 70°C for 20 minutes, then rise to 90°C at 1°C / min and keep for 20 minutes, take it out, rinse with water, and dry at room temperature;

[0031] (2) Immerse in warm water at 60°C, soak for 30 minutes, take out, and dry at room temperature;

[0032] (3) Preparation of dyes: Add sodium carboxymethyl cellulose to water, stir for 24 hours, slowly add cationic dye Fluorescent Yellow X-10GFF300%, stir and mix well; cationic dye Fluorescent Yellow X-10GFF300%, carboxymethylcellulose The mass ratio of sodium and water is 1:0.2:102;

[0033] (4) Fluorescent dyeing: immerse the cotton fabric treated in step (2) in the dye prepared in step (3) for dyeing, pH=6, bath ratio 30:1, initial temperatu...

Embodiment 3

[0035] A kind of production technology of fluorescent cotton fabric of the present invention comprises steps:

[0036] (1) Modification of cotton fabric: immerse cotton fabric in 18g / L polyepichlorohydrin aminate solution, pH=10, bath ratio 30:1, initial temperature 30°C, rise to 5°C / min Keep at 70°C for 20 minutes, then rise to 90°C at 1°C / min and keep for 20 minutes, take it out, rinse with water, and dry at room temperature;

[0037] (2) Immerse in warm water at 60°C, soak for 30 minutes, take out, and dry at room temperature;

[0038] (3) Preparation of dyes: Add sodium carboxymethyl cellulose to water, stir for 24 hours, slowly add cationic dye Fluorescent Yellow X-10GFF300%, stir and mix well; cationic dye Fluorescent Yellow X-10GFF300%, carboxymethylcellulose The mass ratio of sodium and water is 1:0.1:95;

[0039] (4) Fluorescent dyeing: immerse the cotton fabric treated in step (2) in the dye prepared in step (3) for dyeing, pH=6, bath ratio 30:1, initial temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com