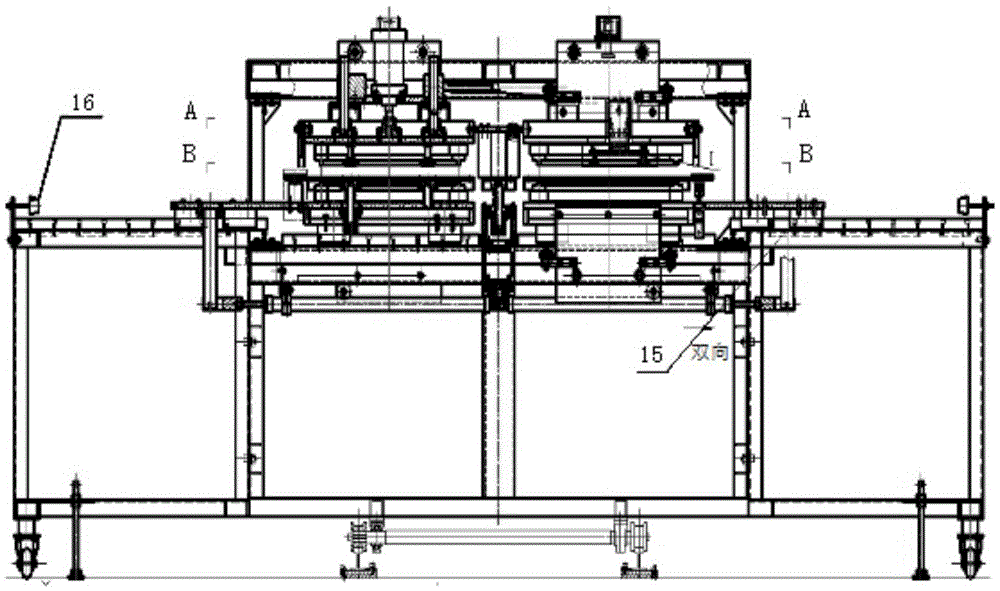

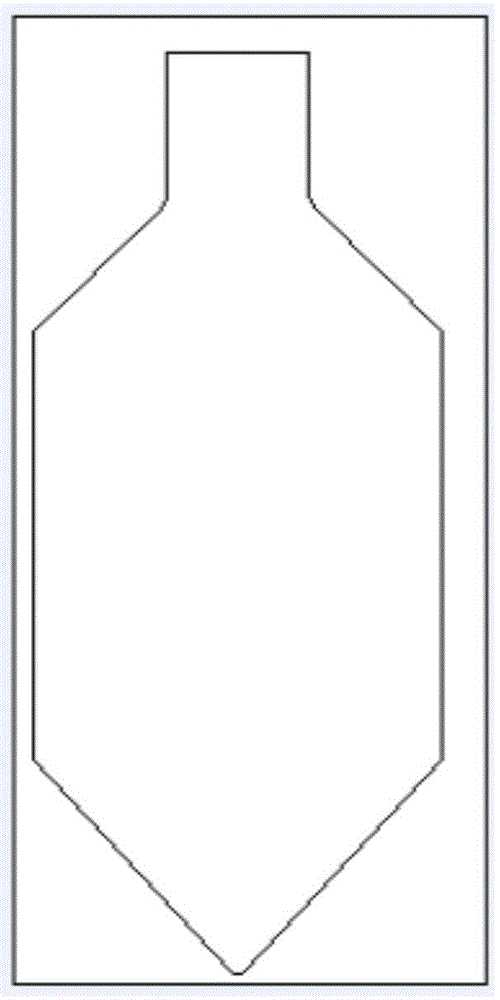

Automatic two-way blank-pressing ton bag machine

A ton bag machine, automatic technology, applied in the direction of envelope/bag manufacturing machinery, container manufacturing machinery, paper/cardboard containers, etc., can solve the problems of high labor intensity, low welding seam quality, low output, etc. Efficiency and product quality, high labor intensity, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

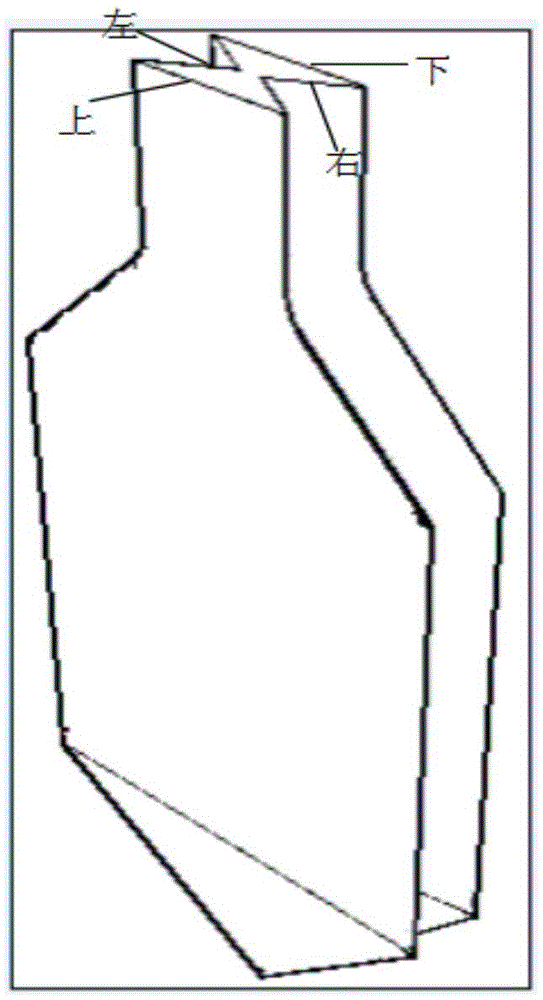

[0021] The present invention includes two machines, that is, a type I machine and a type II machine that are connected. Frame 14, first cylinder 7, second cylinder 6, third cylinder 4, fourth cylinder 1, fifth cylinder 9, floating support mechanism 2, floating plate 3, pressure head 10, insert plate 5, linear guide pair 8, Suction cup 12, upper ironing knife 11, lower ironing knife 13, and upper workbench 17; there are four inserting plates 5, and the four inserting plates 5 are respectively arranged on the left and right sides of the Type I machine and the left and right sides of the Type II machine, The frame 14 is provided with a linear guide rail pair 8, the linear guide rail pair 8 is equipped with a flashboard 5, and the flashboard 5 is lifted to the required position by the second cylinder 6, and the first A cylinder 7 drives the board 5 to advance and retreat, and the third cylinder 4 arranged on the frame 14 plays the role of supporting the front end of the board 5 so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com