Tissue paper compounding hot melt adhesive and preparation method thereof

A technology of hot-melt adhesives and paper towels, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of increased energy consumption, not too high adhesive strength, short shelf life, etc., to reduce transportation costs, good reliability Peelability and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

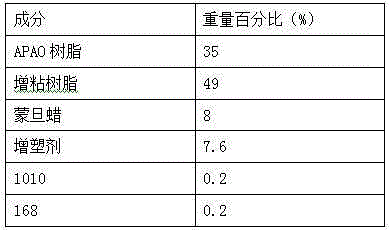

[0033] (1) Accurately weigh the raw materials in the following weight percentages:

[0034] Table 1:

[0035]

[0036] (2) Mix the above-mentioned montan wax, APAO resin, 1010, and 168 evenly, heat to 90°C, and vacuumize while stirring until each component is completely melted; then add tackifying resin and plasticizer, and heat at 90°C After melting, vacuumize the system and keep it warm for 1 hour. After stirring and mixing evenly, the material is pumped into a single-screw extruder, cooled, and pelletized to form a hot melt adhesive for paper towel compounding.

Embodiment 2

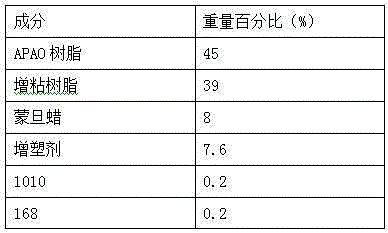

[0038] (1) Accurately weigh the raw materials in the following weight percentages:

[0039] Table 2:

[0040]

[0041] (2) Mix the above-mentioned montan wax, APAO resin, 1010, and 168 evenly, heat to 100°C, and vacuumize while stirring until each component is completely melted; then add tackifying resin and plasticizer, and heat at 110°C After melting, vacuumize the system and keep it warm for 1 hour. After stirring and mixing evenly, the material is pumped into a single-screw extruder, cooled, and pelletized to form a hot melt adhesive for paper towel compounding.

Embodiment 3

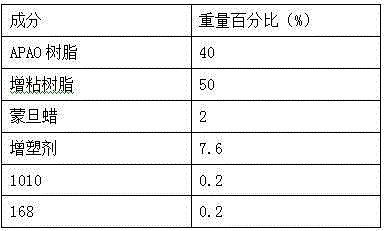

[0043] (1) Accurately weigh the raw materials in the following weight percentages:

[0044] table 3:

[0045]

[0046] (2) Mix the above wax, APAO resin, 1010, 168 evenly, heat to 120°C, evacuate while stirring until all components are completely melted; then add tackifying resin and plasticizer, and heat to melt at 130°C , evacuate the system, keep it warm for 1 hour, stir and mix evenly, pump the material into a single-screw extruder, cool, cut into pellets, and obtain a hot melt adhesive for paper towel compounding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com