Method for manufacturing bonded fabric with improved moisture permeability

A technology for laminating fabrics and manufacturing methods, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc. Problems such as fabric moisture permeability, to achieve the effect of ensuring fabric feel, improving moisture permeability, and improving moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

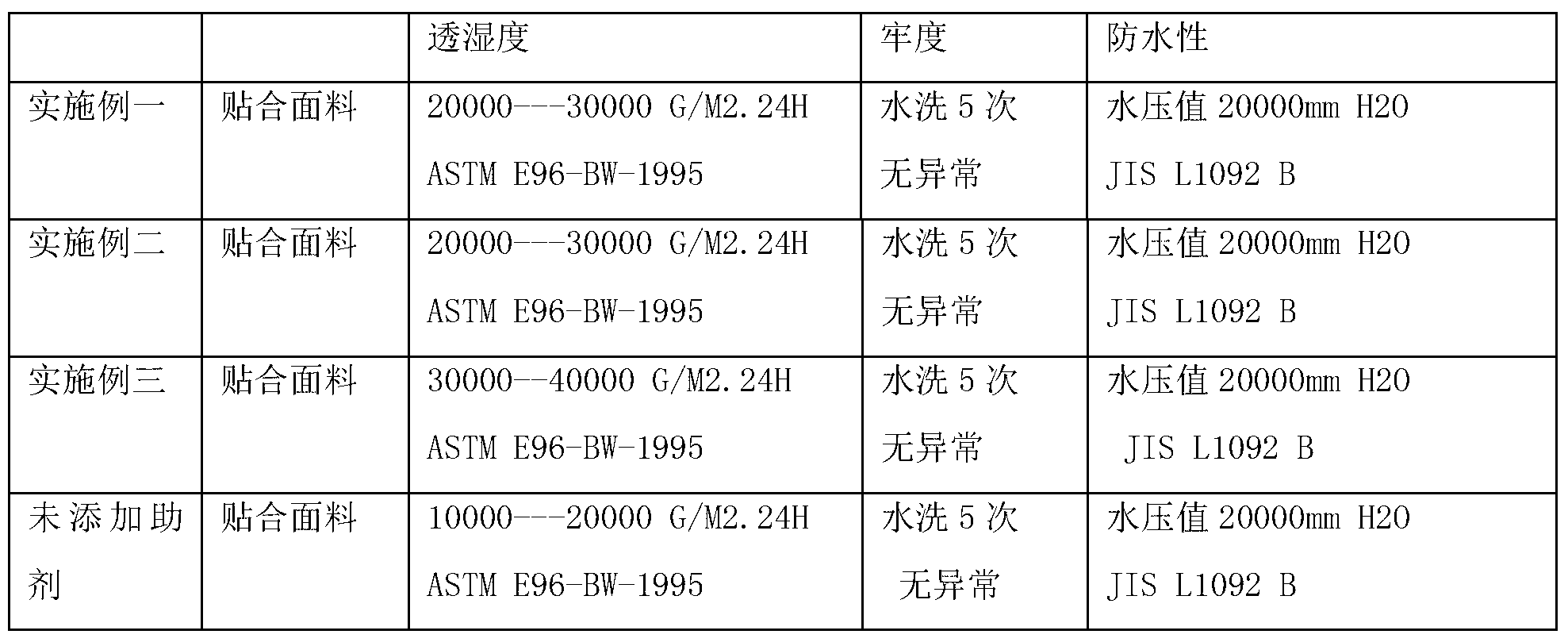

Embodiment 1

[0033] A method for manufacturing a laminated fabric that improves moisture permeability. The laminated fabric includes a top rubber layer, a primer layer, and a fabric layer. The fabric layer is a fabric with a relatively high surface roughness. The manufacturing method includes:

[0034] a. Glue configuration: Mix 100 parts by weight of hydrophilic waterproof and moisture-permeable polyurethane resin with a solid content of 25-35%, 10 parts by weight of surface glue solvent, 1 part of anti-sticking agent, and 1 part of release agent Surface glue, the surface glue solvent is selected from DMF or toluene, and the anti-adhesive agent is selected from silicon derivatives, more preferably waxed silicon dioxide. The release agent is organic macromolecular silicon, and the hydrophilic waterproof and moisture-permeable polyurethane resin is one-component polyurethane resin. The viscosity of the surface glue is controlled at 500-3000cps;

[0035] The configuration process of the sur...

Embodiment 2

[0047]This embodiment is basically the same as Example 1, except that there are differences in the formulation. The proportion of the top glue in this embodiment is: 100 parts by weight of a hydrophilic waterproof and moisture-permeable polyurethane resin with a solid content of 25-35%, 50 parts by weight 10 parts of surface glue solvent, 5 parts of anti-adhesive agent, and 10 parts of release agent are mixed to configure the surface glue; the proportioning of primer is: 100 parts by weight of polyurethane resin with solid content of 40-60%, 50 parts of Peptizer, 10 parts by weight of bridging agent, 5 parts of bridging accelerator, 30 parts of hydrophilic waterproof and moisture-permeable polyurethane resin with a solid content of 25-35% in the surface glue, and 5 parts of PUR additives are mixed to configure the bottom Glue, the viscosity of the primer is controlled at 2000-8000cps. The addition of PUR additives in the primer can enhance the bonding strength of the primer, s...

Embodiment 3

[0060] This embodiment is basically the same as Example 1, except that there are differences in the formula. The proportion of the surface glue in this embodiment is: 100 parts by weight of a hydrophilic waterproof and moisture-permeable polyurethane resin with a solid content of 25-35%, 25 parts by weight 10 parts of surface glue solvent, 3 parts of anti-sticking agent, and 6 parts of release agent are mixed to configure the surface glue; the ratio of primer is: 100 parts by weight of polyurethane resin with a solid content of 40-60%, 25 parts of Peptizer, 5 parts by weight of bridging agent, 3 parts of bridging accelerator, 15 parts of hydrophilic waterproof and moisture-permeable polyurethane resin with a solid content of 25-35% in the surface glue, and 10 parts of PUR additives mixed to configure the bottom Glue, the viscosity of the primer is controlled at 2000-8000cps. The addition of PUR additives in the primer can enhance the bonding strength of the primer, so the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com