Composition dispersing liquid for fabric waterproof treatment

A water-repellent treatment and composition technology, applied in fiber treatment, textiles and papermaking, liquid-repellent fibers, etc., can solve the problems of fabrics feeling astringent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 70 parts by mass of stearyl acrylate, 30 parts by mass of dodecyl acrylate, 5 parts by mass of alcohol a, 5 parts by mass of triethylene glycol, 2 parts by mass of S-60, 4 parts by mass of AEO-9, 1 part by mass of AC -1810, 3 parts by mass of octadecyltrimethylammonium chloride, 0.5 parts by mass of acetic acid and 200 parts by mass of water were added to the reaction kettle, and the temperature was raised to 40-45°C for pre-emulsification. Then homogenize under high pressure for 30 minutes at a pressure of 30 MPa, transfer the homogenized solution to the reaction kettle, and start stirring. 0.5 parts by mass of the initiator AIBA was dissolved in 2 parts by mass of water to form a homogeneous solution, which was added to the reaction kettle. Then the temperature was raised to 70-75° C. for 5 hours of reaction to obtain the dispersion liquid of the fabric waterproofing treatment composition of the present invention.

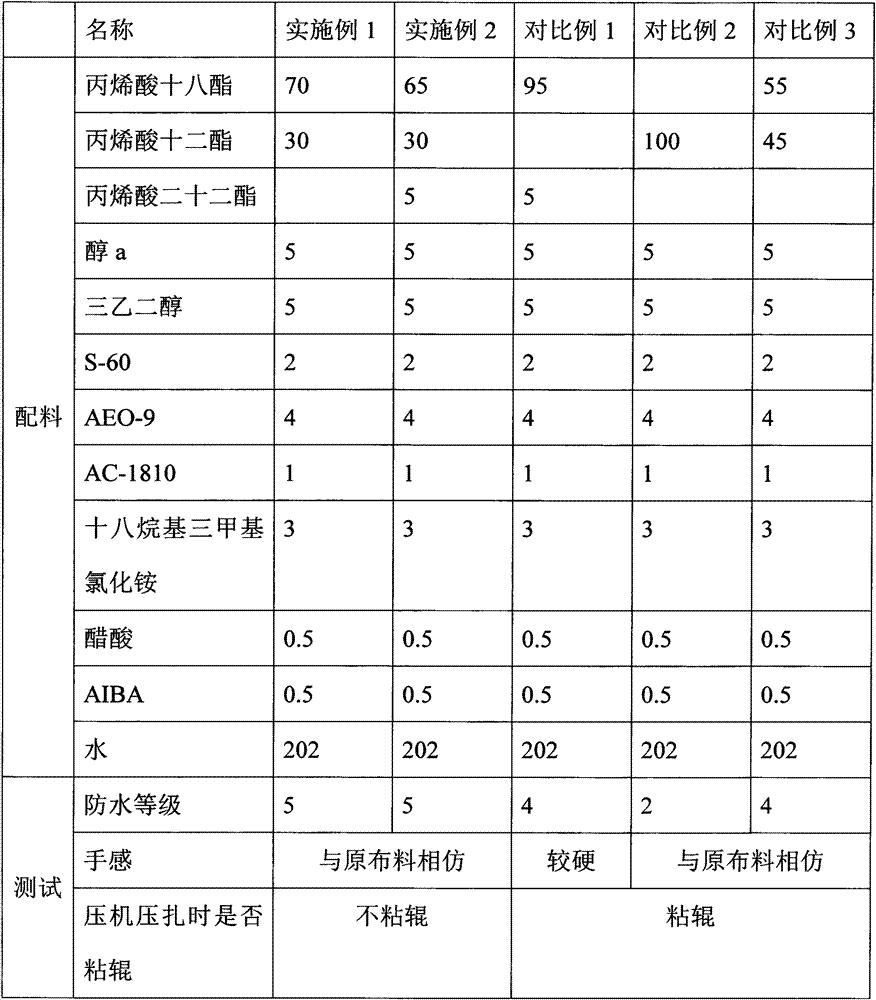

Embodiment 2 and comparative example 1~3

[0064] Using the same process as in Example 1, the specific formula is shown in Table 2.

[0065] Table 2 Process formula table (mass parts in the table)

[0066]

[0067] AIBA is azobisisobutylamidine hydrochloride, the same below.

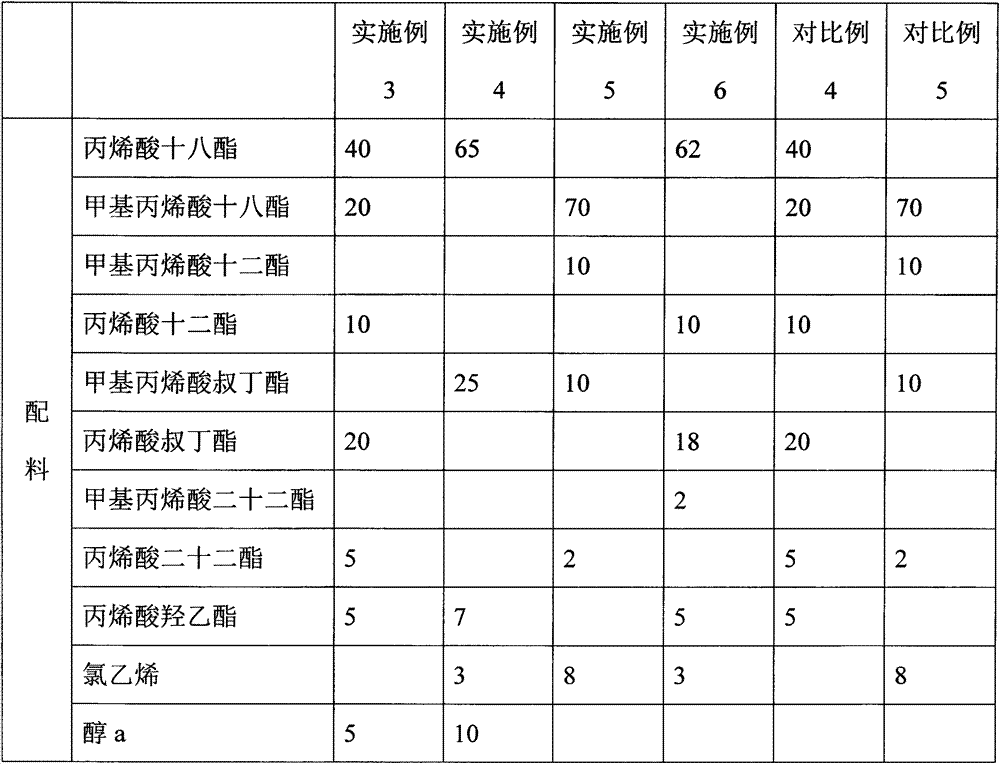

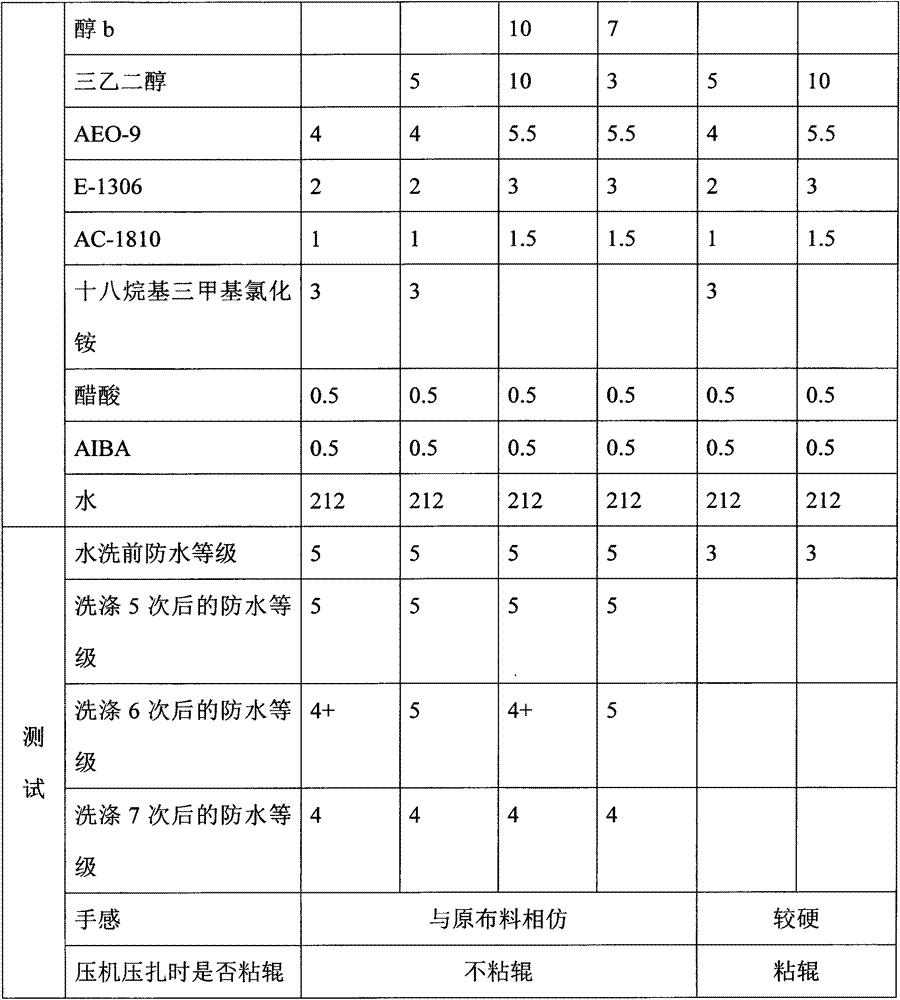

Embodiment 3 and comparative example 4

[0069] Using the same process as in Example 1, the specific formula is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com