Heating-antibacterial antistatic and high-simulation cashmere blended knitting yarn and fabric thereof

A technology of antistatic and blended yarn, which is applied in the direction of textile, fabric, textile and paper making, etc. It can solve the problems affecting the aesthetics of cashmere sweaters, expensive cashmere products, and limited cashmere resources, so as to ensure the hand feel, plump appearance, good Antibacterial and antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Spinning

[0021] Antibacterial, anti-static, high-fidelity cashmere blended yarn with 26 counts, composed of 7% wool, 8% acrylic, 15% nylon compounded with graphene, 30% polyester compounded with graphene, and 40% high-simulation cashmere fiber , The high-simulation cashmere fiber is composed of 10% rabbit hair fiber, 30% cashmere-like high-shrinkage acrylic fiber and 60% cashmere-like acrylic fiber. The fineness of the cashmere-like high-shrinkage acrylic fiber is 0.8 denier and the length is 38mm.

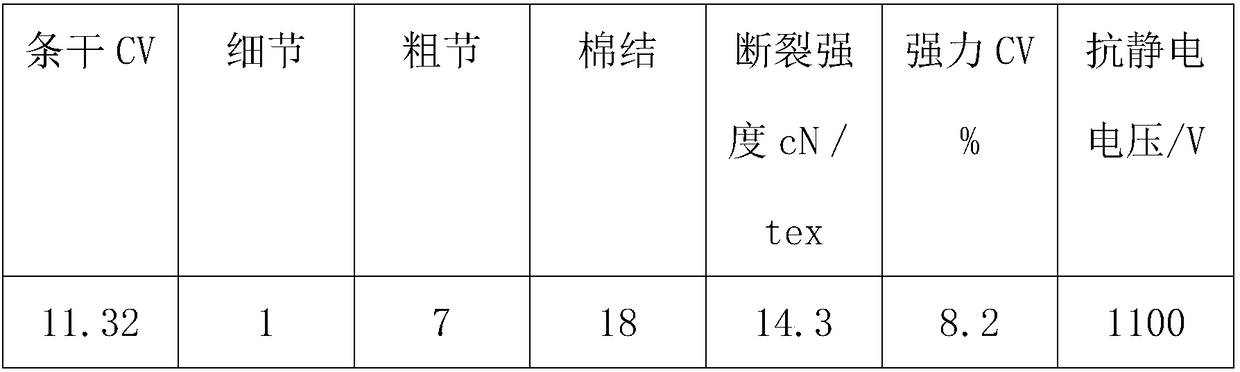

[0022] The performance parameters of the yarn obtained in the present embodiment are:

[0023]

[0024] (2) Weaving

[0025] A heat-generating, antibacterial and antistatic high-simulation cashmere fabric is produced from antibacterial high-simulation cashmere blended yarn through ply twisting, dyeing, knitting and post-finishing steps.

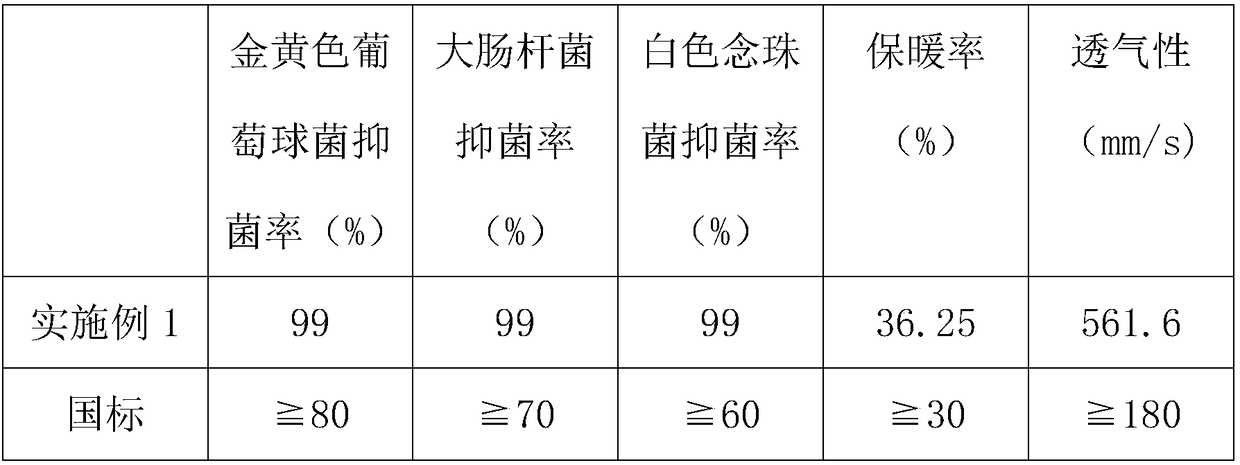

[0026] The performance parameter of the lining of present embodiment gained is:

[0027]

Embodiment 2

[0029] (1) Spinning

[0030] Fever, antibacterial and antistatic high-simulation cashmere blended yarn specification is 28 yarns, made of 10% wool, 10% acrylic, 15% nylon compounded with graphene, 30% polyester compounded with graphene, 35% high-simulation cashmere fiber The high-simulation cashmere fiber is composed of 10% rabbit hair fiber, 30% cashmere-like high-shrinkage acrylic fiber and 60% cashmere-like acrylic fiber. The fineness of the cashmere-like high-shrinkage acrylic fiber is 0.8 denier and the length is 38mm.

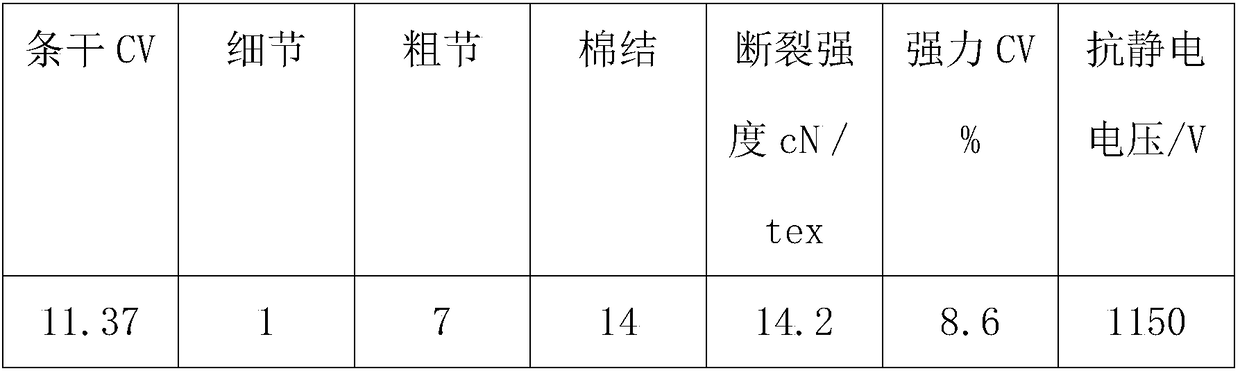

[0031] The performance parameters of the yarn obtained in the present embodiment are:

[0032]

[0033] (2) Weaving

[0034] A heat-generating, antibacterial and antistatic high-simulation cashmere fabric is produced from antibacterial high-simulation cashmere blended yarn through ply twisting, dyeing, knitting and post-finishing steps.

[0035] The performance parameter of the lining of present embodiment gained is:

[0036]

Embodiment 3

[0038] (1) Spinning

[0039] Fever, antibacterial, antistatic, high-simulation cashmere blended yarn specification is 32 yarns, composed of 15% wool, 10% acrylic, 15% nylon compounded with graphene, 30% polyester compounded with graphene, 30% high-simulation cashmere fiber , The high-simulation cashmere fiber is composed of 10% rabbit hair fiber, 30% cashmere-like high-shrinkage acrylic fiber and 60% cashmere-like acrylic fiber. The fineness of the cashmere-like high-shrinkage acrylic fiber is 0.8 denier and the length is 38mm.

[0040] The performance parameters of the yarn obtained in the present embodiment are:

[0041]

[0042] (2) Weaving

[0043] A heat-generating, antibacterial and antistatic high-simulation cashmere fabric is produced from antibacterial high-simulation cashmere blended yarn through ply twisting, dyeing, knitting and post-finishing steps.

[0044] The performance parameter of the lining of present embodiment gained is:

[0045]

[0046] The inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com