Titanium dioxide textile and preparation method thereof

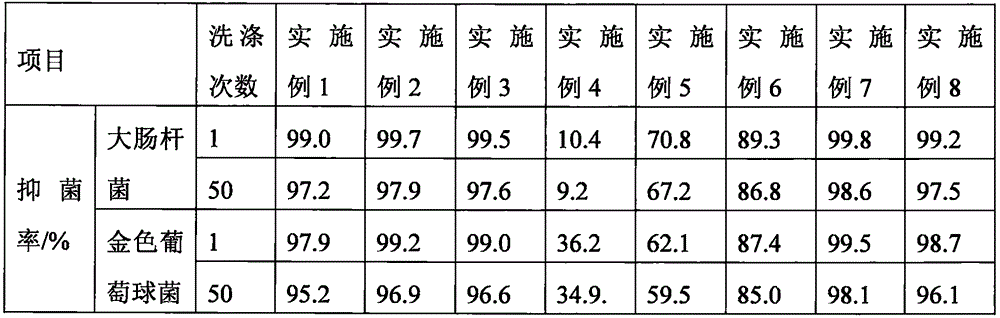

A technology of titanium dioxide and antibacterial textiles, applied in the antibacterial field, can solve the problems of poor washing resistance, lack of broad-spectrum, and high dosage of antibacterial agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of described titanium dioxide antibacterial textile, comprises the steps:

[0031] S100 Add titanium dioxide antibacterial agent into water, add dispersant, adhesive and thickener in turn and stir at a constant speed to disperse evenly to obtain a slurry;

[0032] S200 Scouring pure cotton cloth in lye at 60-80°C for 5-15 minutes, then drying at 100°C; and

[0033] S300 Use the screen printing method to evenly coat the slurry on the fabric at 15-30°C, pre-bake the coated fabric at 80-100°C for 3-8 minutes, and then dry it at 100-140°C Bake at the bottom for 2-5 minutes to obtain titanium dioxide antibacterial textiles.

[0034] Wherein, the preparation of described titanium dioxide antibacterial agent comprises steps:

[0035] S110 slowly add tetrabutyl titanate into 1-acetoxy-3-propanesulfonate imidazolium bromide, and stir under the condition of 600-800r / min to prepare a 40%-50% mixed solution;

[0036] S120 Add water and metal-organic framew...

Embodiment 1

[0055] A kind of preparation method of titanium dioxide antibacterial agent is:

[0056] (1) Preparation of metal organic framework material MIL-100:

[0057] Fully dissolve ferric chloride hexahydrate in deionized water, add trimesic acid and stir for 30 minutes to form a mixed solution, put the resulting mixed solution into an autoclave, react at 130°C for 70 hours, cool to room temperature, and wash with methanol several times , boiled in boiling methanol for 12 hours, and dried in vacuum at 150°C for 12 hours to obtain MIL-100, wherein the mass volume ratio of ferric chloride hexahydrate to deionized water was 0.05g / mL, ferric chloride hexahydrate and benzenetricarboxylic acid The mass ratio is 1.5:1;

[0058] (2) Slowly add tetrabutyl titanate into the ionic liquid 1-acetoxy-3-propanesulfonate imidazolium bromide, and stir at room temperature at 600 r / min to prepare a 40% mixed solution;

[0059] (3) Add distilled water and MIL-100 of the same quality as the ionic liqui...

Embodiment 2

[0067] A kind of preparation method of titanium dioxide antibacterial agent is:

[0068] (1) Preparation of metal organic framework material MIL-100:

[0069] Fully dissolve ferric chloride hexahydrate in deionized water, add trimesic acid and stir for 30 minutes to form a mixed solution, put the resulting mixed solution into an autoclave, react at 130°C for 70 hours, cool to room temperature, and wash with methanol several times , boiled in boiling methanol for 12 hours, and dried in vacuum at 150°C for 12 hours to obtain MIL-100, wherein the mass volume ratio of ferric chloride hexahydrate to deionized water was 0.05g / mL, ferric chloride hexahydrate and benzenetricarboxylic acid The mass ratio is 2:1;

[0070] (2) Slowly add tetrabutyl titanate into the ionic liquid 1-acetoxy-3-propanesulfonate imidazolium bromide, and stir at room temperature at 800 r / min to prepare a 50% mixed solution;

[0071] (3) Add distilled water and MIL-100 of the same quality as the ionic liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com